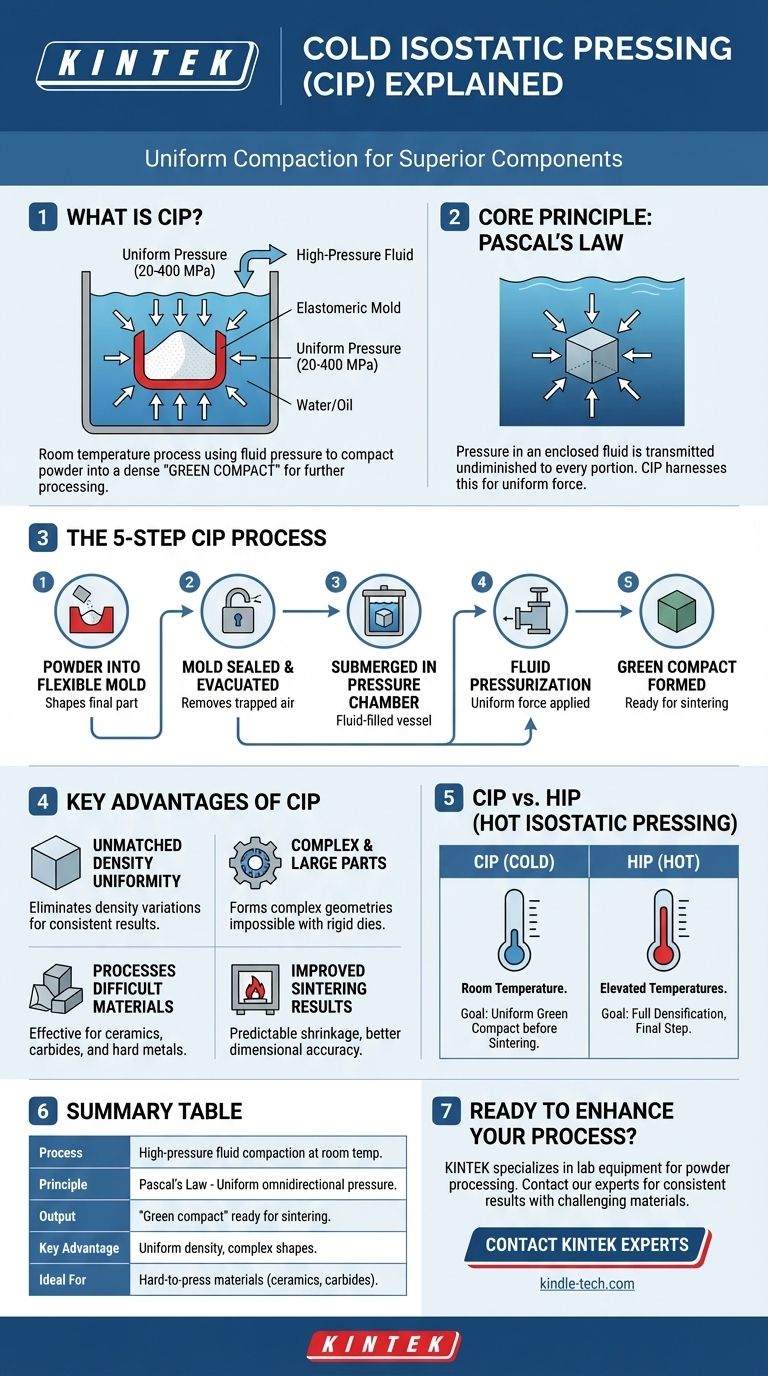

In essence, cold isostatic pressing (CIP) is a manufacturing process that uses high-pressure fluid to uniformly compact a powder into a solid shape. It operates at or near room temperature, applying pressure equally from all directions to create a dense, consolidated component known as a "green compact" that is ready for further processing.

By placing a powder-filled flexible mold into a liquid and pressurizing the entire chamber, cold isostatic pressing leverages fluid dynamics to overcome the limitations of traditional mechanical pressing, resulting in parts with superior density and uniformity.

How Cold Isostatic Pressing Works

To understand CIP, it's essential to grasp both its guiding principle and its practical execution. The method is valued for its elegant simplicity and highly effective results.

The Core Principle: Pascal's Law

The process functions based on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

An easy analogy is an object submerged deep underwater. The pressure it experiences comes equally from all sides, not just from above. CIP harnesses this exact principle in a controlled industrial setting.

The Step-by-Step Process

- A powder material is first placed into a flexible, elastomeric mold (like rubber or urethane). This mold defines the shape of the final part.

- The mold is sealed, often under vacuum, to remove any trapped air that could interfere with compaction.

- The sealed mold is then submerged in a pressure chamber filled with a working fluid, typically water (often with a corrosion inhibitor), oil, or a glycol mixture.

- An external pump pressurizes this fluid, with pressures ranging from 20 to 400 MPa. This immense pressure is exerted uniformly on the entire surface of the flexible mold.

- The powder inside the mold is compacted into a solid, cohesive mass. This resulting object is called a "green compact" or "green body" because it has handling strength but has not yet been fully strengthened through a final heating process.

Key Advantages of Using CIP

The uniform pressure application gives CIP several distinct advantages over conventional uniaxial (one-direction) pressing methods.

Unmatched Density Uniformity

Because pressure is applied from all directions simultaneously, CIP eliminates the density variations and internal stress points that can occur when pressing from only one or two directions. This results in a highly uniform green compact.

Forming Complex and Large Parts

Rigid metal dies can only form relatively simple shapes. The use of a flexible mold and fluid pressure allows for the creation of intricate, complex geometries and very large components that would be impossible to produce otherwise.

Processing Difficult Materials

Many advanced materials, such as hard metals, carbides, and certain ceramics, are notoriously difficult to compact effectively using traditional methods. CIP provides the necessary force and uniformity to successfully press these challenging powders.

Improved Final Sintering Results

The high, uniform density of the green compact means it will shrink less and more predictably during the final sintering (high-temperature firing) stage. This leads to better dimensional accuracy and a lower scrap rate for the finished parts.

Understanding the Trade-offs and Context

While powerful, CIP is not a one-step solution. It's a specific tool used for a specific purpose within a larger manufacturing workflow.

It Is an Intermediate Step

A crucial point to understand is that CIP produces a green compact, not a finished product. This part has enough strength to be handled and machined, but it requires a subsequent thermal treatment, like sintering, to fuse the powder particles and achieve its final mechanical properties and density.

Cold vs. Hot Isostatic Pressing (HIP)

CIP is often confused with its high-temperature counterpart, Hot Isostatic Pressing (HIP).

- Cold Isostatic Pressing (CIP): Used at room temperature to create a uniform green compact from powder. The primary goal is shaping and achieving uniform density before final sintering.

- Hot Isostatic Pressing (HIP): Used at elevated temperatures to fully densify a part, close internal porosity in castings, or bond dissimilar materials. It is often a final or near-final manufacturing step.

Equipment and Process Considerations

The process requires a specialized pressure vessel designed to withstand severe and repeated high-pressure cycles. The workflow involves multiple stages—powder preparation, molding, pressing, and sintering—which must be managed effectively.

When to Consider Cold Isostatic Pressing

Deciding to use CIP depends entirely on the material, the complexity of the part, and the desired quality of the final product.

- If your primary focus is producing complex shapes with uniform density: CIP is ideal because fluid pressure conforms to any geometry, eliminating the weak spots and density gradients common in uniaxial pressing.

- If your primary focus is working with hard-to-compact powders like carbides or ceramics: Use CIP to provide the immense, uniform force required to create a viable green compact from these challenging materials.

- If your primary focus is minimizing distortion and improving dimensional control during final sintering: Start with a CIP-produced green part, as its exceptional uniformity leads to more predictable and consistent results after firing.

Ultimately, cold isostatic pressing is a powerful tool for creating high-quality, uniform powder compacts that serve as a superior foundation for subsequent manufacturing operations.

Summary Table:

| Key Aspect | Details |

|---|---|

| Process | Uses high-pressure fluid to compact powder at room temperature |

| Principle | Pascal's Law - uniform pressure from all directions |

| Output | 'Green compact' ready for sintering |

| Key Advantage | Unmatched density uniformity and ability to form complex shapes |

| Ideal For | Hard-to-press materials like ceramics, carbides, and intricate parts |

Ready to produce complex, high-density parts with superior uniformity?

KINTEK specializes in lab equipment and consumables, providing solutions for all your powder processing needs. Our expertise in isostatic pressing technology can help you achieve consistent results for even the most challenging materials and geometries.

Contact our experts today to discuss how our equipment can enhance your laboratory's capabilities and streamline your manufacturing process.

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Vacuum Cold Mounting Machine for Sample Preparation

People Also Ask

- What is an example of cold isostatic pressing? Achieve Uniform Density in Complex Parts

- What is the specific function of a cold isostatic press in the sintering process of LiFePO4? Maximize Battery Density

- What is isostatic pressing used for? Achieve Superior Density and Uniformity in Critical Components

- What is the purpose of using a sealed laminated bag in CIP for battery components? Ensure Purity and High Density.

- For which types of components and materials is semi-isostatic pressing particularly suitable? Optimize Your Production

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What is the process of cold isostatic pressing? Achieve Uniform Density in Complex Parts

- Why is isostatic pressing better than regular uniaxial pressing when manufacturing ceramics? Achieve Superior Density and Complex Shapes