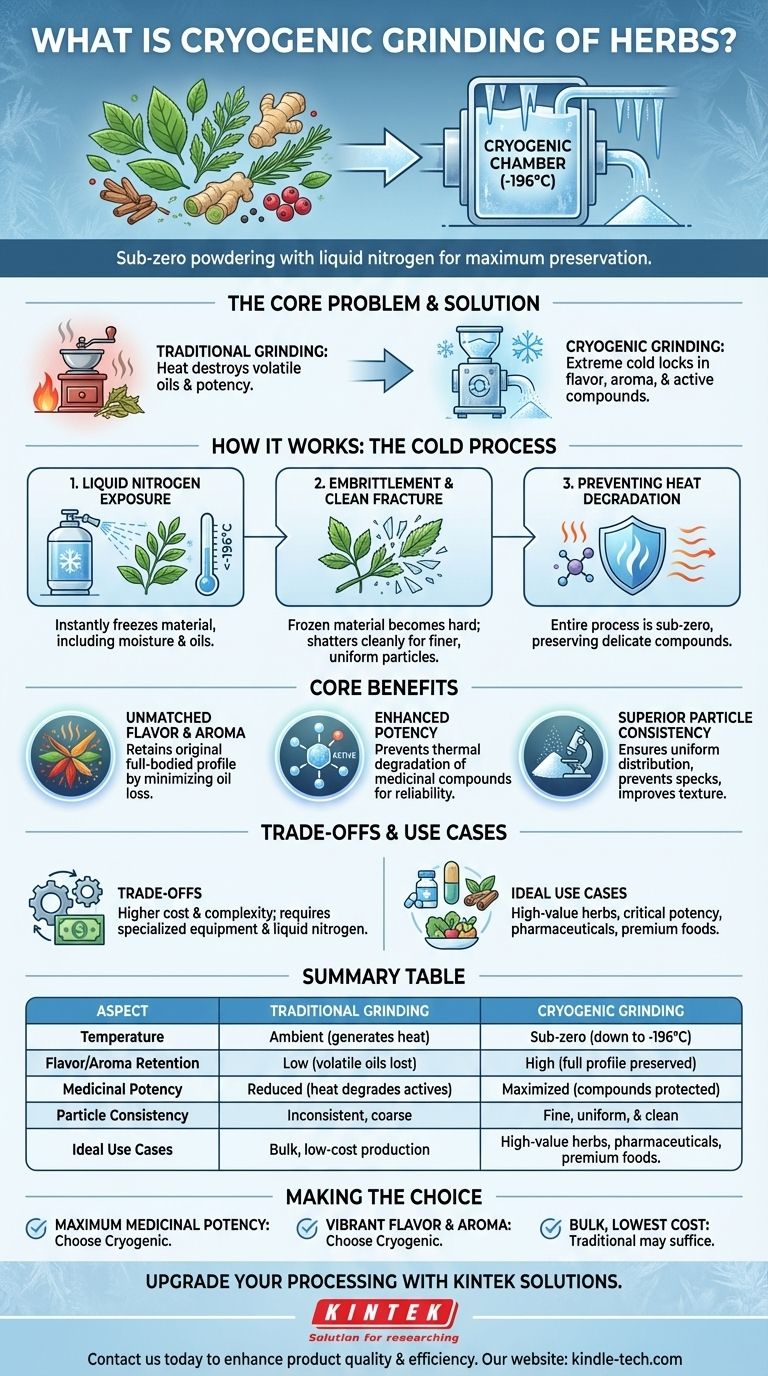

In essence, cryogenic grinding is a process where herbs and spices are powdered at sub-zero temperatures, often between 0°C and -196°C. The material is rapidly frozen using a cryogen like liquid nitrogen, which makes it brittle and easy to crush into a fine powder. This extreme cold protects the herb's delicate chemical structure from the heat and friction generated during conventional grinding.

The central problem with traditional grinding is that the heat it produces destroys the volatile oils and active compounds that give herbs their flavor, aroma, and medicinal potency. Cryogenic grinding solves this by using extreme cold to lock in these essential qualities, resulting in a significantly more potent and aromatic final product.

How Cryogenic Grinding Protects the Herb

Traditional grinding methods rely on friction and mechanical force, which generates significant heat. This heat causes a substantial loss of the delicate compounds that define an herb's value. Cryogenic grinding fundamentally changes this dynamic.

The Role of Liquid Nitrogen

The process begins by exposing the herb or spice to an extremely cold substance, most commonly liquid nitrogen. This instantly freezes the material, including all the moisture and volatile oils contained within its cellular structure.

Embrittlement and Clean Fracture

Freezing makes the plant material hard and brittle. Instead of being smeared, torn, or heated by the grinder's blades, the embrittled herb shatters cleanly like glass.

This clean fracture results in a finer and more uniform particle size. It also requires less energy to grind the material, as the brittleness makes it easier to break down.

Preventing Heat Degradation

The most critical advantage is the prevention of heat damage. The entire process occurs at sub-zero temperatures, ensuring that the volatile aromatic compounds (terpenes, esters) and sensitive medicinal components are not evaporated or degraded.

The Core Benefits of Cryogenic Grinding

By preserving the herb's natural state, this method produces a powder that is superior in nearly every measurable way.

Unmatched Flavor and Aroma Retention

Volatile oils are directly responsible for the taste and smell of herbs and spices. Cryogenic grinding has been scientifically proven to minimize the loss of these oils, retaining the original, full-bodied flavor profile that is often diminished in conventional powders.

Enhanced Pharmacological Potency

For medicinal herbs used in Ayurveda or other therapeutic systems, the active compounds are everything. By preventing their thermal degradation, cryogenic grinding ensures the final product delivers the intended pharmacological effect, making it more effective and reliable for medicinal use.

Superior Particle Consistency

The clean shattering of the frozen material allows for a much finer and more consistent grind. This is crucial in food production, as it prevents large specks, ensures uniform flavor distribution, and improves the overall texture of the final product.

Understanding the Trade-offs

While the benefits are clear, cryogenic grinding is a specialized industrial process with specific considerations. It is not a technique you would typically perform at home.

Higher Cost and Complexity

The primary trade-off is cost. The use of liquid nitrogen and the need for specialized, insulated grinding equipment make the process significantly more expensive and complex than standard ambient-temperature grinding.

When Is It Necessary?

This method is most valuable for high-value herbs and spices where aroma and medicinal potency are critical. For hardy seeds or applications where a slight loss in quality is acceptable, the added expense may not be justified. Its commercial application is primarily in the food and pharmaceutical industries where quality control is paramount.

Making the Right Choice for Your Product

The decision to use cryogenically ground herbs depends entirely on your goal for the final product.

- If your primary focus is maximum medicinal potency: Cryogenic grinding is the superior choice to ensure the herb's active compounds are preserved and bioavailable.

- If your primary focus is vibrant flavor and aroma: This method is the gold standard for producing spices that retain their true character for culinary applications.

- If your primary focus is bulk production at the lowest cost: Traditional grinding may be sufficient, but you must accept the inherent trade-off in lost flavor and potency.

Ultimately, choosing a cryogenically ground product is an investment in preserving the complete essence and integrity of the original herb.

Summary Table:

| Aspect | Traditional Grinding | Cryogenic Grinding |

|---|---|---|

| Temperature | Ambient (generates heat) | Sub-zero (down to -196°C) |

| Flavor/Aroma Retention | Low (volatile oils lost) | High (full profile preserved) |

| Medicinal Potency | Reduced (heat degrades actives) | Maximized (compounds protected) |

| Particle Consistency | Inconsistent, coarse | Fine, uniform, and clean |

| Ideal Use Cases | Bulk, low-cost production | High-value herbs, pharmaceuticals, premium foods |

Upgrade your herb processing with precision cryogenic grinding solutions from KINTEK.

Are you in the food, pharmaceutical, or nutraceutical industry and need to preserve the full potency and aroma of your herbal products? KINTEK specializes in advanced lab equipment and consumables designed for optimal sample preparation. Our expertise ensures you achieve the finest, most consistent powders while protecting sensitive compounds.

Contact us today to discuss how our solutions can enhance your product quality and efficiency.

Get in touch with our experts now

Visual Guide

Related Products

- Small Cryogenic Grinder Cryomill Cryogrinder with Liquid Nitrogen for Laboratory Use

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration

- Why is a cryogenic grinder required for cured alkyd resin HRMAS NMR? Ensure Structural Integrity & Sample Precision

- How does cryomilling work? Achieve Superior Nanostructures with Cryogenic Milling

- What was the cryogenic grinding process compared against in the study? Cryogenic vs. Dry Grinding Analysis

- What is a grinder used in labs? Essential for Homogeneous Sample Preparation & Analysis