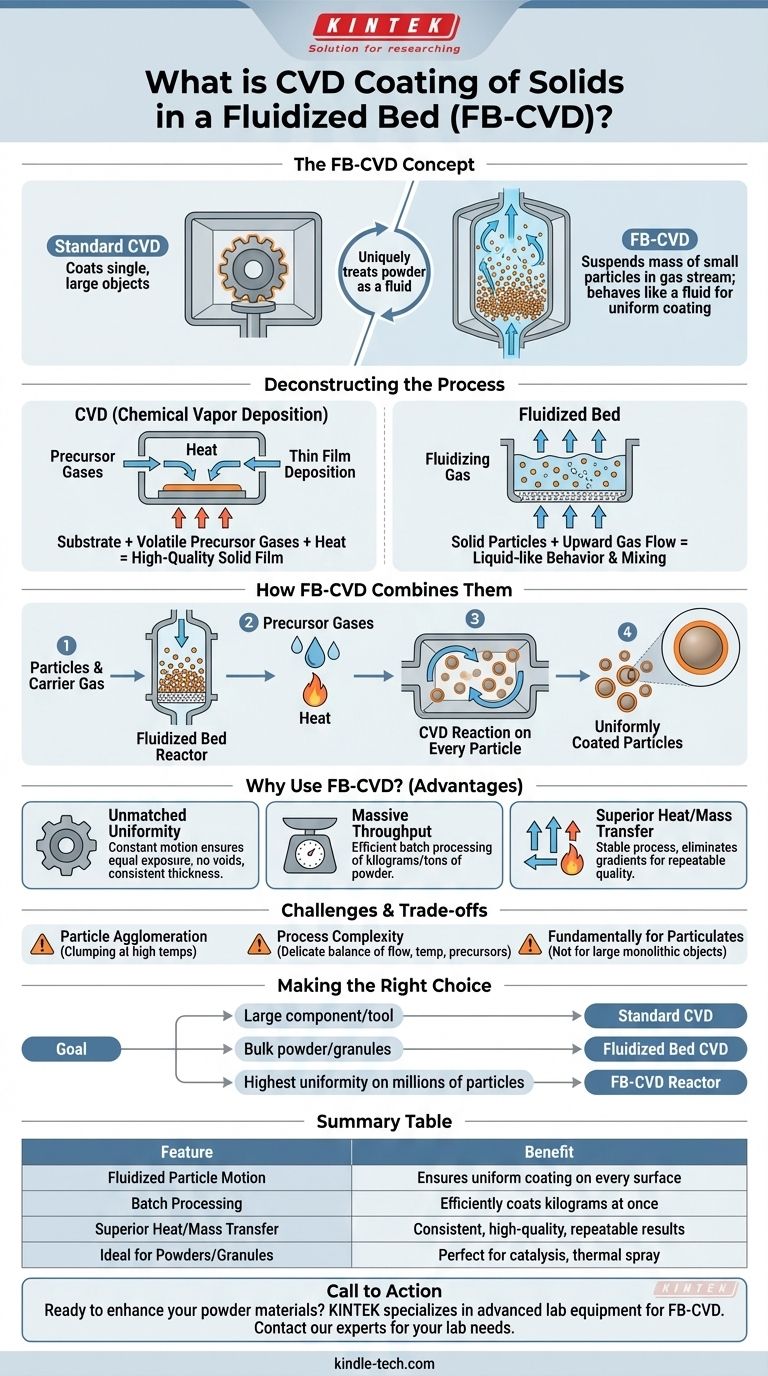

Fluidized Bed Chemical Vapor Deposition (FB-CVD) is an advanced manufacturing process for applying exceptionally uniform, thin-film coatings onto the surface of a large quantity of small particles or powders simultaneously. Unlike standard CVD, which coats stationary objects, this method suspends the particles in a gas stream, causing them to behave like a fluid and ensuring every particle is coated evenly.

While standard Chemical Vapor Deposition (CVD) is designed for coating single, large objects, FB-CVD uniquely treats a mass of fine powders or granules as a fluid. This approach ensures every individual particle receives a consistent, high-performance coating, making it unmatched for efficiently modifying the surface properties of bulk particulate materials.

Deconstructing the Process: CVD Meets Fluidization

To understand FB-CVD, it's essential to first understand its two core technologies: Chemical Vapor Deposition and fluidization.

What is Chemical Vapor Deposition (CVD)?

CVD is a process where a substrate (the object to be coated) is placed in a reaction chamber and exposed to one or more volatile precursor gases.

When heated, these gases react or decompose on and near the substrate's surface, depositing a thin, solid film. This film is often highly pure, dense, and of exceptional quality.

CVD coatings are used to provide properties like wear resistance, corrosion resistance, high-temperature protection, or specific electrical characteristics.

What is a Fluidized Bed?

A fluidized bed is a physical phenomenon where a quantity of a solid particulate substance (like sand or powder) is placed under conditions that cause it to behave like a liquid.

This is achieved by pumping a "fluidizing" gas (such as argon or nitrogen) up through the particle bed from below. At the right velocity, the gas flow counteracts gravity, suspending the particles and causing them to mix and circulate vigorously, much like boiling water.

How FB-CVD Combines Them

FB-CVD integrates these two concepts into a single, powerful process. The particles to be coated are placed into a reactor and turned into a fluidized bed using a carrier gas.

The chemical precursor gases required for the CVD reaction are then introduced into this fluidizing gas stream. The entire chamber is heated to the necessary reaction temperature.

As the particles tumble and circulate within the hot, reactive gas environment, the CVD reaction occurs on the surface of every individual particle, building up a highly uniform coating.

Why Use a Fluidized Bed for CVD?

Choosing FB-CVD over other methods is driven by the unique advantages it offers for coating powders and small parts.

Unmatched Coating Uniformity

The constant, random motion of the particles within the bed is the key benefit. It ensures that all surfaces of every particle are equally exposed to the precursor gases, preventing voids and creating a film of consistent thickness.

Massive Throughput and Efficiency

FB-CVD is a batch process capable of coating kilograms or even tons of powder at once. This is vastly more efficient than attempting to coat a large number of small parts individually.

Superior Heat and Mass Transfer

The fluid-like behavior of the bed eliminates temperature gradients and ensures the precursor gases are distributed evenly throughout the reactor. This process stability leads to highly repeatable and predictable coating quality.

Understanding the Trade-offs and Challenges

While powerful, FB-CVD is a complex process with specific limitations that make it unsuitable for certain applications.

Particle Agglomeration

At the high temperatures required for CVD, the freshly coated particles can become sticky. This can cause them to clump together, or "agglomerate," which disrupts fluidization and leads to non-uniform coatings.

Process Complexity

Controlling the delicate balance between gas flow rate, temperature, precursor concentration, and particle dynamics is significantly more complex than in a standard CVD reactor for a single part.

Fundamentally for Particulates

This technique is purpose-built for powders, granules, and other small, flowable solids. It is not suitable for coating large, monolithic objects like semiconductor wafers or machine tools.

Making the Right Choice for Your Goal

The decision to use FB-CVD depends entirely on the form of the material you need to coat.

- If your primary focus is coating a single, large component (like a tool or electronic part): Standard Chemical Vapor Deposition (CVD) is the appropriate method.

- If your primary focus is modifying the surface properties of a bulk powder or many small granules: Fluidized Bed CVD (FB-CVD) is the most efficient and effective solution.

- If your primary focus is achieving the highest possible coating uniformity on millions of individual particles for applications like catalysis or thermal spray powders: The superior heat and mass transfer of an FB-CVD reactor makes it the ideal choice.

Ultimately, selecting the right deposition technique requires matching the unique capabilities of the process to the physical form of your material.

Summary Table:

| Feature | Benefit |

|---|---|

| Fluidized Particle Motion | Ensures uniform coating on every particle surface |

| Batch Processing | Efficiently coats kilograms of powder at once |

| Superior Heat/Mass Transfer | Consistent, high-quality, repeatable results |

| Ideal for Powders/Granules | Perfect for catalysis, thermal spray feedstock |

Ready to enhance your powder materials with a uniform, high-performance coating?

KINTEK specializes in advanced lab equipment and consumables for processes like Fluidized Bed CVD. Whether you're developing catalysts, thermal spray powders, or other advanced materials, our expertise can help you achieve superior surface properties efficiently.

Contact our experts today to discuss how FB-CVD solutions can meet your specific laboratory needs.

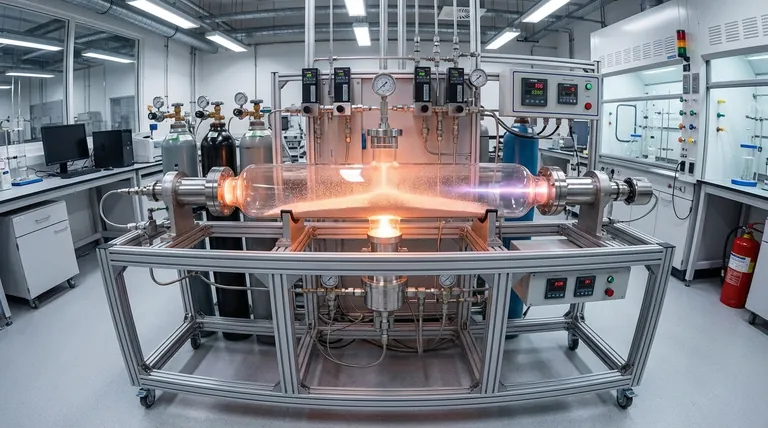

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods