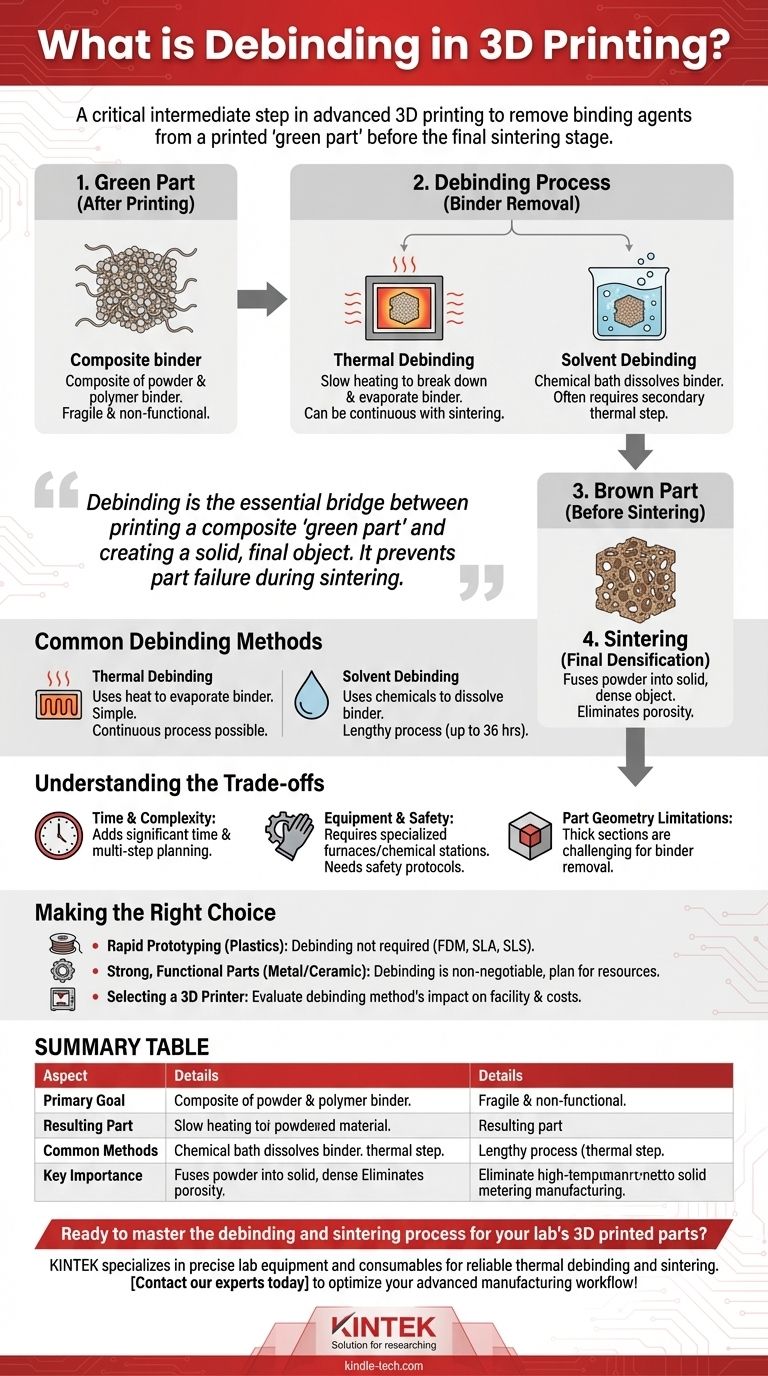

In advanced 3D printing processes, debinding is the critical intermediate step where binding agents are removed from a freshly printed part. This is done to purify the object, leaving behind only the core material—typically metal or ceramic powder—in preparation for the final sintering stage, which fuses the powder into a solid, dense object.

Debinding is the essential bridge between printing a composite "green part" and creating a solid, final object. It systematically removes the temporary polymer binder, which is necessary for printing but would ruin the part if left in during final densification.

Why Debinding is Necessary: The "Green Part" Problem

Many advanced 3D printing methods cannot print with pure metal or ceramic powder directly. Instead, they use a composite material where the powder is mixed with a polymer binder, creating a printable feedstock similar to a plastic filament or paste.

The Role of Binders in Printing

Binders act as a temporary glue. They give the material the right consistency to be extruded or shaped by the printer, holding the metal or ceramic powder together in the desired form. The initial object that comes off the printer is known as a "green part."

A green part is not a functional metal or ceramic object. It is a composite of powder and polymer, often fragile and possessing none of the desired final material properties.

From "Green" to "Brown"

The goal of debinding is to remove the polymer binder from the green part. This is a delicate process that must be done without disturbing the loosely-held-together powder particles.

Once the binder is removed, the part is referred to as a "brown part." It is now extremely fragile—essentially a porous skeleton of powdered material—but it is ready for the final step.

The Consequence of Not Debinding

If a green part were placed directly into a high-temperature sintering furnace, the trapped polymer binder would rapidly burn or boil. This would create intense internal pressure, causing the part to crack, bloat, or even explode, completely destroying it. Debinding ensures a controlled, gentle removal of the binder first.

Common Debinding Methods

The specific debinding method is determined by the type of binder used. The two most common approaches are thermal and solvent-based.

Thermal Debinding

This is the most straightforward method, where the part is slowly heated in a furnace or kiln. The heat breaks down and evaporates the polymer binder.

Some modern materials are designed for a streamlined process where debinding and sintering occur in a single, continuous heating cycle within one furnace.

Solvent Debinding

In this process, the green part is submerged in a chemical bath. The solvent is specifically chosen to dissolve the primary binding agent without affecting the powdered material.

This method often requires a secondary thermal debinding step to remove any remaining binding agents before sintering. The duration can be lengthy, sometimes taking up to 24-36 hours depending on the part's size and geometry.

Understanding the Trade-offs

Debinding is a powerful enabler for creating metal and ceramic parts, but it introduces significant considerations into the manufacturing workflow.

Time and Complexity

Debinding adds a substantial amount of time to the total part-making process. Unlike direct plastic printing, you cannot simply print an object and use it immediately. The multi-step nature requires careful planning and process control.

Equipment and Safety

This step requires specialized equipment beyond the 3D printer itself, such as a calibrated furnace, a chemical debinding station, or both. Handling high temperatures and specific chemicals also requires heat-resistant gloves, proper ventilation, and established safety protocols.

Part Geometry Limitations

The effectiveness of debinding is heavily influenced by a part's geometry. Very thick or dense sections are challenging because it takes much longer for the heat or solvent to penetrate the core and remove all the binder. This can be a critical design constraint.

Making the Right Choice for Your Process

Understanding debinding is key to choosing the right manufacturing technology for your specific needs. It marks the line between simple prototyping and more complex, industrial-grade part production.

- If your primary focus is rapid prototyping with plastics: You will likely not encounter debinding, as common processes like FDM, SLA, or SLS do not require it.

- If your goal is to produce strong, functional metal or ceramic parts: Debinding is a non-negotiable part of the workflow that you must plan and budget for in terms of time, equipment, and expertise.

- If you are selecting a metal 3D printing system: Carefully evaluate the specific debinding method it uses, as this will directly impact your facility requirements, turnaround time, and operational costs.

Ultimately, knowing when and why debinding is required empowers you to look beyond the printer itself and understand the entire ecosystem needed to achieve your final part.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Goal | Remove temporary polymer binder from a 3D printed "green part." |

| Resulting Part | Creates a fragile "brown part" ready for sintering. |

| Common Methods | Thermal (heating) and Solvent (chemical bath). |

| Key Importance | Prevents part failure (cracking/explosion) during final high-temperature sintering. |

Ready to master the debinding and sintering process for your lab's 3D printed parts? KINTEK specializes in the precise lab equipment and consumables you need for reliable thermal debinding and sintering cycles. Our expertise ensures you achieve dense, high-quality metal and ceramic components efficiently. Contact our experts today to optimize your advanced manufacturing workflow!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the different types of EAF? AC vs. DC and Charging Methods Explained

- What is the movement of heat in a vacuum? Mastering Thermal Radiation for Precise Control

- What is the primary role of a high-temperature industrial furnace in the carbothermal reduction process?

- How does a high-temperature calcination furnace contribute to the formation of Si-RuO2 catalysts? Optimize Your Synthesis

- Which heat treatment process is a softening process? Understand Annealing for Superior Metal Workability

- What is the function of a vacuum drying oven in catalyst recovery? Maximize Cycle Life and Maintain Active Sites

- Which furnace is used for heating metals? Match the Right Technology to Your Metalworking Goal

- What is the process of quenching? A Guide to Controlled Metal Hardening