In essence, fast pyrolysis is a thermochemical conversion process designed to rapidly transform waste biomass into a liquid biofuel. By heating organic material like wood chips or agricultural residue to high temperatures in an oxygen-free environment, the process cracks the solid structure into vapor, which is then condensed into a useful product known as bio-oil.

While often viewed as a waste management technique, fast pyrolysis is more accurately described as a high-speed chemical refinery. Its core purpose is to maximize the yield of liquid bio-oil from low-value biomass, creating a direct pathway to renewable fuels and chemicals.

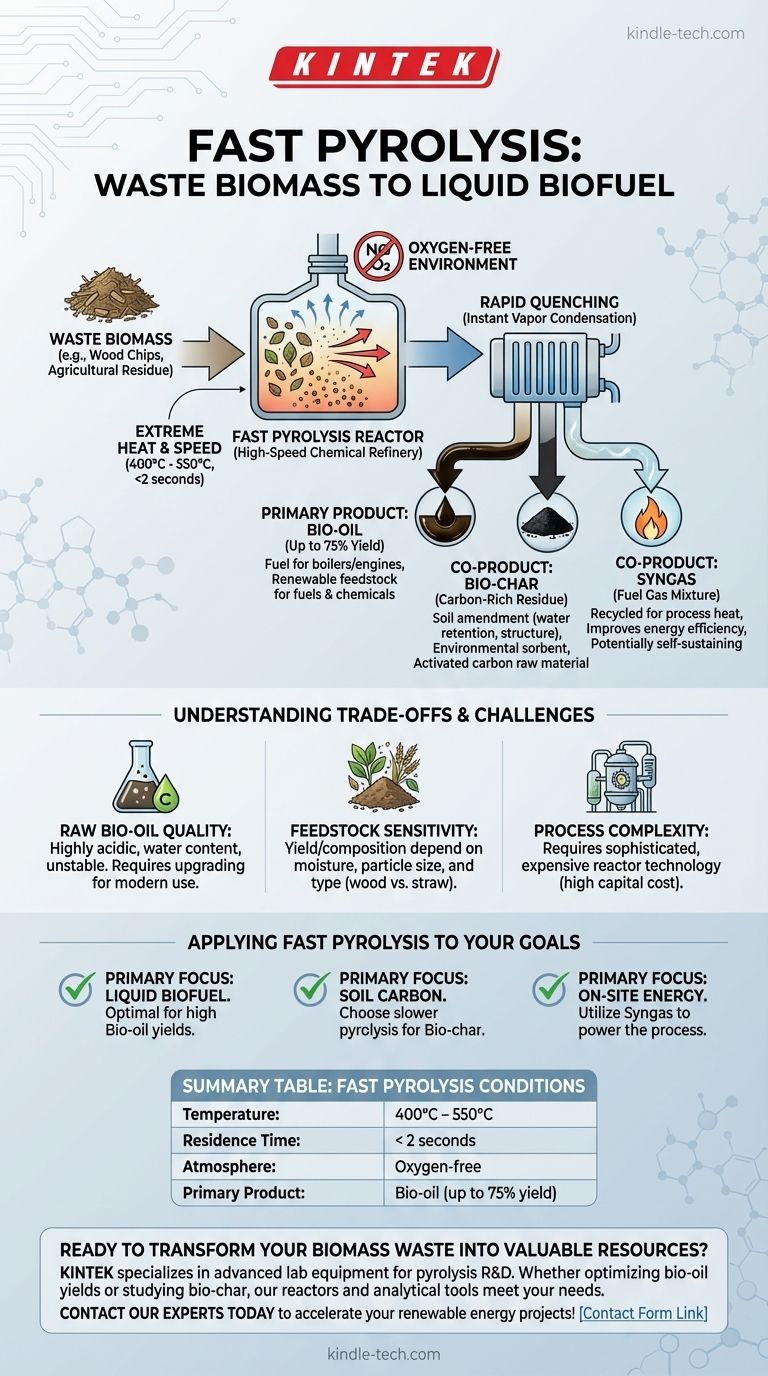

How Fast Pyrolysis Works: The Core Principles

The effectiveness of fast pyrolysis hinges on precise control over three key parameters: temperature, time, and atmosphere.

The Role of Extreme Heat and Speed

Fast pyrolysis operates at moderately high temperatures, typically between 400°C and 550°C. The biomass is subjected to this heat at an extremely high rate.

This "thermal shock" instantly vaporizes the organic compounds. The residence time—the duration the biomass spends at this peak temperature—is incredibly short, usually less than two seconds. This speed is critical to prevent the vapors from further breaking down into less desirable gases and solid char.

The Oxygen-Free Environment

The entire process occurs in the absence of oxygen. This is the fundamental difference between pyrolysis and combustion (burning).

Without oxygen, the biomass cannot burn. Instead, the heat causes its long-chain polymers (like cellulose and lignin) to thermally decompose, or "crack," into smaller, volatile molecules.

Rapid Quenching to Capture Liquid

Immediately after the brief, intense heating phase, the resulting hot vapors and aerosols are rapidly cooled, or quenched.

This rapid condensation is what captures the product in its liquid form, creating bio-oil. If the cooling were slow, these valuable compounds could continue to react and break down.

The Three Key Products and Their Value

Fast pyrolysis deliberately optimizes conditions to favor liquid production, but it always yields three distinct products, each with its own applications.

Primary Product: Bio-oil

This dark, viscous liquid is the main prize of fast pyrolysis, often constituting up to 75% of the product by weight.

Bio-oil can be used as a fuel for industrial boilers and some engines, or as a renewable feedstock for producing transportation fuels and specialty chemicals.

Co-product: Bio-char

This solid, carbon-rich material is the residue left behind after the volatile components have vaporized. It is chemically similar to charcoal.

Bio-char is a valuable soil amendment that improves water retention and soil structure. It is also used as a sorbent for environmental cleanup or as a raw material for producing activated carbon.

Co-product: Syngas

This mixture of non-condensable gases includes hydrogen, carbon monoxide, and methane. While produced in smaller quantities, it plays a vital role in process efficiency.

The syngas is flammable and is almost always redirected to provide the heat for the pyrolysis reactor, making the process more energy-efficient and potentially self-sustaining.

Understanding the Trade-offs and Challenges

While powerful, fast pyrolysis is not a silver bullet. A clear-eyed view of its limitations is essential for successful implementation.

The Quality of Raw Bio-oil

Raw bio-oil is not a "drop-in" replacement for petroleum fuels. It is highly acidic, contains a significant amount of water, and can be unstable over time.

For use in modern engines or refineries, bio-oil typically requires a secondary upgrading process to improve its properties, which adds complexity and cost.

Feedstock Sensitivity

The exact yield and composition of the products depend heavily on the type and condition of the biomass feedstock.

Factors like moisture content, particle size, and the chemical makeup of the biomass (e.g., wood vs. straw) must be carefully managed to ensure consistent and efficient operation.

Process Complexity

Achieving the extremely high heating rates and short residence times required for fast pyrolysis demands sophisticated and expensive reactor technology, such as circulating fluidized bed or ablative reactors. This makes it more capital-intensive than slower pyrolysis methods that prioritize bio-char production.

Applying Fast Pyrolysis to Your Goals

Your strategy for using pyrolysis should be dictated by your desired end product.

- If your primary focus is liquid biofuel production: Fast pyrolysis is the optimal thermal conversion pathway due to its exceptionally high bio-oil yields.

- If your primary focus is creating stable carbon for soil: A slower pyrolysis process, which is optimized to maximize bio-char yield at the expense of oil, is the more direct and effective choice.

- If your primary focus is on-site energy from waste: The syngas co-product is a key asset that can be used to power the process itself, reducing external energy costs.

By understanding its specific outputs and limitations, you can strategically leverage fast pyrolysis to convert waste streams into valuable resources.

Summary Table:

| Key Parameter | Fast Pyrolysis Condition |

|---|---|

| Temperature | 400°C – 550°C |

| Residence Time | < 2 seconds |

| Atmosphere | Oxygen-free |

| Primary Product | Bio-oil (up to 75% yield) |

Ready to transform your biomass waste into valuable resources? KINTEK specializes in advanced lab equipment for pyrolysis research and development. Whether you're optimizing bio-oil yields or studying bio-char applications, our reactors and analytical tools are designed to meet your laboratory's precise needs. Contact our experts today to explore how our solutions can accelerate your renewable energy projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Non Consumable Vacuum Arc Induction Melting Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds