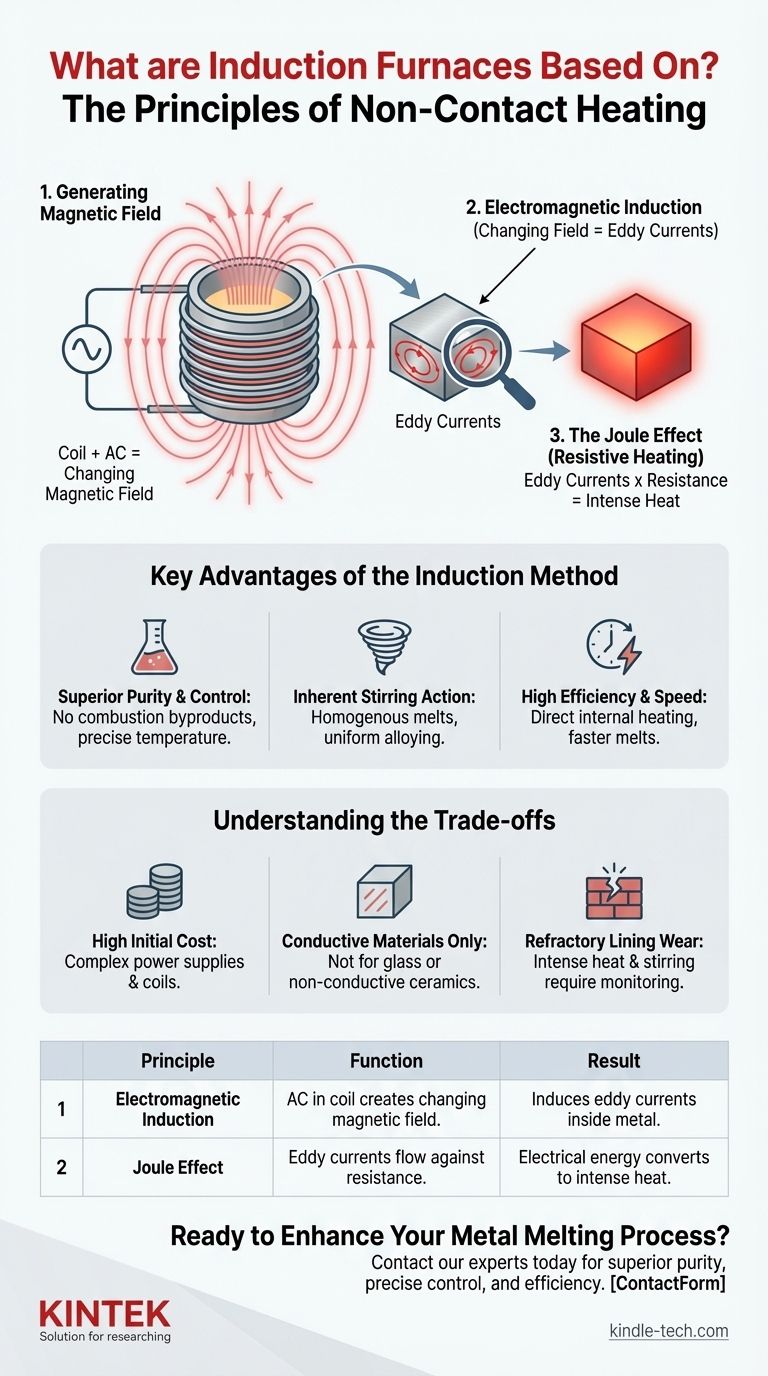

Induction furnaces operate on a combination of two core physical principles. They harness the power of electromagnetic induction to create electrical currents inside a conductive material, and then rely on the Joule effect to convert that electrical energy into intense heat. This process allows the furnace to melt metal without any direct contact from a flame or heating element.

An induction furnace functions by turning the metal itself into the source of heat. It uses a powerful, changing magnetic field to induce internal electrical currents, resulting in a clean, contained, and highly efficient melting process.

How Induction Heating Works: A Step-by-Step Breakdown

To understand an induction furnace, it’s helpful to view the process as a sequence of three distinct physical events. The system is essentially a large-scale transformer where the furnace coil is the primary and the metal to be melted acts as a single-turn secondary.

Step 1: Generating the Magnetic Field

The process begins with a large, durable coil, typically made of copper tubing, that is wrapped around a crucible containing the metal charge. A high-frequency alternating current (AC) is passed through this coil. This flow of electricity generates a powerful and rapidly changing magnetic field in the space within the coil.

Step 2: Electromagnetic Induction

According to Faraday's Law of Induction, a changing magnetic field will induce an electrical current in any conductor placed within it. The metal pieces inside the crucible are conductive, so the furnace's magnetic field induces circular electrical currents within them. These are known as eddy currents.

Step 3: The Joule Effect (Resistive Heating)

The final step is the generation of heat. As the induced eddy currents flow through the metal, they encounter the material's natural electrical resistance. This resistance impedes the flow of electricity and, as a result, converts the electrical energy directly into thermal energy (heat). This phenomenon is known as the Joule effect or resistive heating, causing the metal's temperature to rise rapidly to its melting point.

Key Advantages of the Induction Method

The physics behind induction heating provide several distinct operational advantages, which is why it has become a standard in modern foundries for melting iron, steel, copper, and other metals.

Superior Purity and Control

Because the heat is generated within the metal itself, there are no byproducts of combustion (like in a gas furnace) or contaminants from an electrode (like in an arc furnace). This results in a much higher-purity final product. It also allows for extremely precise temperature control.

Inherent Stirring Action

The same magnetic forces that induce the eddy currents also create a stirring action within the molten metal bath. This electromagnetic stirring ensures that the temperature is uniform and that any alloying elements added to the melt are mixed in thoroughly, guaranteeing a homogenous final casting.

High Efficiency and Speed

Induction is a highly efficient process because the heat is generated exactly where it is needed—inside the material. Less energy is lost to the surrounding environment compared to methods that rely on external radiation or convection. This leads to faster melting times and lower energy consumption per ton of metal.

Understanding the Trade-offs

While highly effective, induction furnaces are not without their specific limitations and operational considerations.

High Initial Cost

The power supplies, control systems, and high-current coils required for an induction furnace are complex and represent a significant capital investment compared to simpler fuel-fired furnaces.

Requirement for Conductive Materials

This method's primary limitation is that it only works on materials that are electrically conductive. It cannot be used to directly melt non-conductive materials like glass, certain ceramics, or slag, which may require a conductive crucible to act as an intermediary.

Refractory Lining Wear

The intense heat, combined with the constant motion from electromagnetic stirring, can cause wear on the refractory lining of the crucible. This lining must be carefully monitored and periodically replaced to ensure the furnace's integrity and safety.

Making the Right Choice for Your Goal

Selecting a furnace technology depends entirely on the material, the required quality, and operational priorities.

- If your primary focus is high-purity metal and precise alloy composition: The clean, non-contact heating and inherent stirring of an induction furnace make it the ideal choice.

- If your primary focus is operational speed and energy efficiency: Induction heating is superior because it generates heat directly within the metal, minimizing waste and enabling rapid melts.

- If your primary focus is low initial cost for general-purpose melting: A simpler reverberatory or cupola furnace might be a more economical starting point, despite lower efficiency and purity.

By understanding these core principles, you can recognize why the induction furnace is a cornerstone technology for modern, high-quality metal production.

Summary Table:

| Principle | Function | Result |

|---|---|---|

| Electromagnetic Induction | AC current in a coil creates a changing magnetic field. | Induces eddy currents inside the conductive metal charge. |

| Joule Effect (Resistive Heating) | Eddy currents flow against the metal's electrical resistance. | Electrical energy is converted directly into intense heat. |

Ready to Enhance Your Metal Melting Process?

Understanding the science is the first step. Implementing the right technology is what delivers results. KINTEK specializes in advanced lab equipment and consumables, providing robust induction furnaces that bring these principles to life in your laboratory.

Our solutions are designed for laboratories that demand:

- Superior Purity: Achieve uncontaminated melts with our non-contact heating technology.

- Precise Control: Fine-tune temperatures for consistent, high-quality results.

- Operational Efficiency: Reduce melting times and lower energy consumption per batch.

Let's discuss how an induction furnace can transform your metal production. Contact our experts today for a personalized consultation and see the KINTEK difference for yourself.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How is the temperature in a tube furnace measured and controlled? Master Precise Thermal Processing

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing