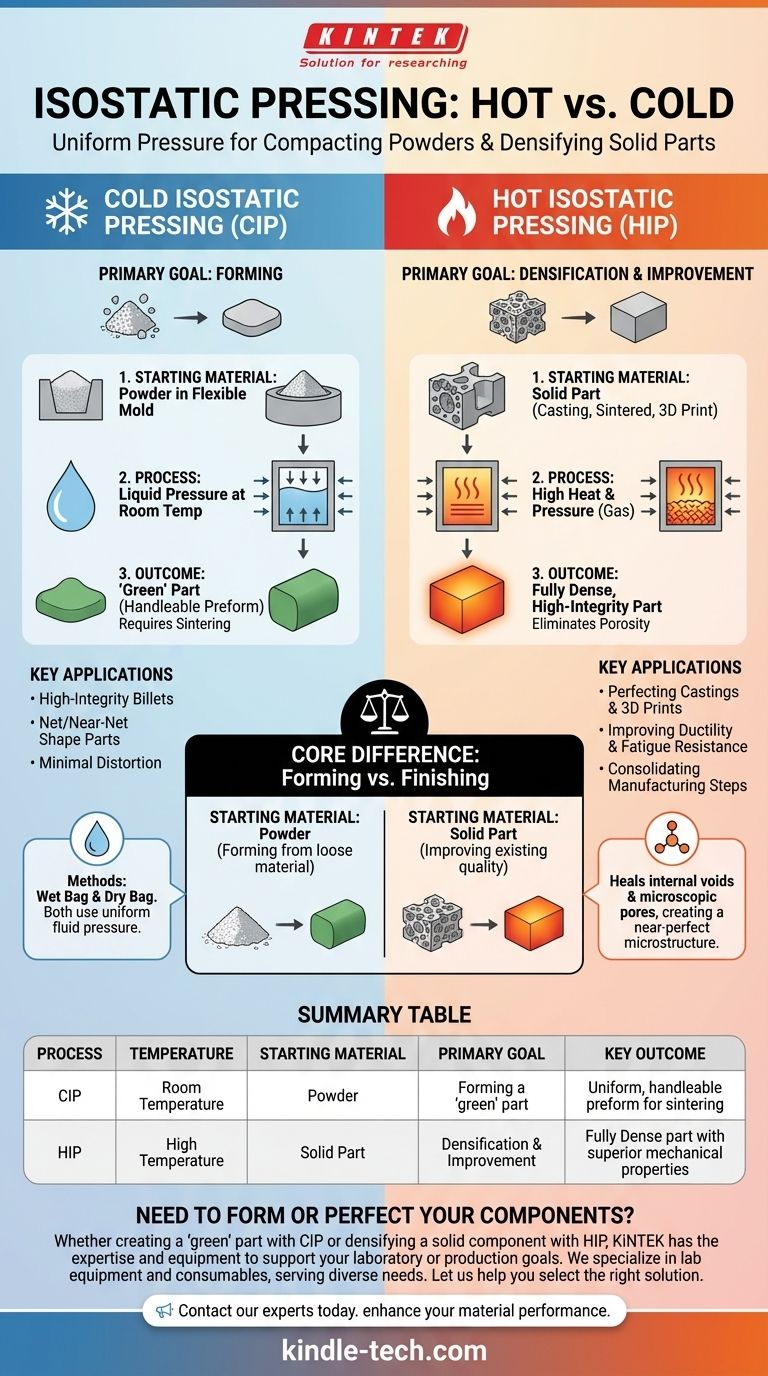

In materials processing, isostatic pressing is a method of compacting powders or densifying solid parts using uniform pressure from all directions. The fundamental difference lies in temperature: Cold Isostatic Pressing (CIP) uses a liquid at room temperature to compact powders into a preliminary shape, while Hot Isostatic Pressing (HIP) uses high heat and pressure to remove internal voids and improve the material properties of an already-formed component.

The choice between hot and cold isostatic pressing is not about which process is superior, but which stage of manufacturing you are addressing. CIP is a forming process for powders, while HIP is a densification and finishing process for solid parts.

The Role of Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing, sometimes called hydrostatic pressing, is a foundational step for creating high-integrity parts from metal or ceramic powders.

The Fundamental Process: Compacting Powder with Fluid

In CIP, a flexible mold containing the powder is submerged in a chamber filled with a liquid, typically water with a corrosion inhibitor or a specialized oil. An external pump pressurizes this fluid, exerting uniform pressure on the mold from all directions.

The Outcome: Creating a 'Green' Part

The result of CIP is a compacted, solid part often called a "raw" or "green" preform. This part has sufficient mechanical strength to be handled and machined, but it has not yet reached its final density or strength.

This green part must undergo a subsequent high-temperature sintering process, which fuses the powder particles together to achieve the final desired material properties.

Key Applications: From Billets to Net-Shape Preforms

CIP is remarkably versatile. It is used to produce simple, high-integrity billets for further processing or to create complex net or near-net shape parts that require minimal finishing after sintering. This process ensures very little distortion or cracking during the final firing.

The Two Methods

There are two primary methods for this process: wet bag isostatic pressing and dry bag isostatic pressing. While they differ in tooling and production volume, both rely on the same principle of uniform fluid pressure.

The Power of Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a transformative finishing process used to perfect components after they have already been formed through casting, sintering, or additive manufacturing (3D printing).

The Fundamental Process: Heat and Pressure for Densification

During HIP, a component is placed inside a high-temperature furnace contained within a pressure vessel. The chamber is heated to just below the material's melting point while being simultaneously subjected to extremely high, uniform pressure.

The Outcome: A Near-Perfect Microstructure

The combination of heat and pressure causes internal voids and microscopic pores within the material to collapse and weld shut on an atomic level. This eliminates porosity and creates a fully dense, uniform microstructure.

Key Applications: Perfecting Castings and 3D Prints

HIP is critical for high-performance industries. It is used to improve the density and relieve thermal stresses in metal castings. For additively manufactured parts, it is an essential step to heal porosity between layers and fix poor layer adhesion.

The result is a dramatic improvement in ductility, fatigue resistance, and overall part integrity.

Beyond Density: Consolidating Manufacturing Steps

Modern HIP systems can also consolidate multiple production steps into a single cycle. By carefully controlling the heating and cooling rates, the process can combine heat treatment, quenching, and aging, significantly reducing total production time.

Understanding the Core Difference: Forming vs. Finishing

The most critical distinction is the process goal and the state of the starting material.

Starting Material: Powder vs. Solid Part

CIP exclusively starts with powder in a flexible mold. Its entire purpose is to compact that powder into a solid shape.

HIP starts with an already solid part. Its purpose is not to change the part's shape, but to improve its internal quality.

Process Goal: Shaping vs. Improving

The goal of CIP is forming. It creates a handleable object from loose material.

The goal of HIP is improvement. It takes a good part and makes it exceptional by eliminating internal flaws.

Making the Right Choice for Your Goal

Selecting the correct process depends entirely on what you need to achieve with your material and component.

- If your primary focus is creating a uniform component from a powder base: Start with Cold Isostatic Pressing to form a high-integrity "green" preform with minimal distortion before sintering.

- If your primary focus is eliminating internal porosity and maximizing the mechanical properties of a solid part (like a casting or 3D print): Use Hot Isostatic Pressing to achieve full density and superior fatigue resistance.

By understanding whether your goal is to form or to perfect, you can confidently select the isostatic process that delivers the required performance for your component.

Summary Table:

| Process | Temperature | Starting Material | Primary Goal | Key Outcome |

|---|---|---|---|---|

| Cold Isostatic Pressing (CIP) | Room Temperature | Powder | Forming a 'green' part | Uniform, handleable preform for sintering |

| Hot Isostatic Pressing (HIP) | High Temperature | Solid Part (e.g., casting, 3D print) | Densification & Improvement | Fully dense part with superior mechanical properties |

Need to Form or Perfect Your Components?

Whether you are working with metal or ceramic powders and need to create a high-integrity 'green' part via Cold Isostatic Pressing (CIP), or you have a solid component like a casting or a 3D printed part that requires densification and enhanced mechanical properties via Hot Isostatic Pressing (HIP), KINTEK has the expertise and equipment to support your laboratory or production goals.

KINTEK specializes in lab equipment and consumables, serving diverse laboratory needs. Let us help you select the right isostatic pressing solution to achieve uniform compaction, eliminate porosity, and improve fatigue resistance in your materials.

Contact our experts today to discuss your specific application and discover how our isostatic pressing solutions can enhance your material performance and manufacturing efficiency.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the industrial applications of filtration? The Essential Guide to Separation Processes

- How does high-power ultrasonic dispersion equipment contribute to graphene exfoliation? Achieve Superior Material Purity

- What device is used to test real diamonds? The Definitive Guide to Diamond Testers & Verification

- What are the disadvantages of a filter press? Key Limitations in Dewatering and Operation

- What precautions should be taken in a chemistry lab? Master the RAMP Framework for Ultimate Safety

- What is the grain size of sputter coating? Control Nanoscale Structure for Your Application

- Which institutions have adjusted their ULT freezer set points to -70°C? Save Energy Without Risking Samples

- What are the factors affecting the quality of powder in powder metallurgy? Optimize Your Manufacturing Process