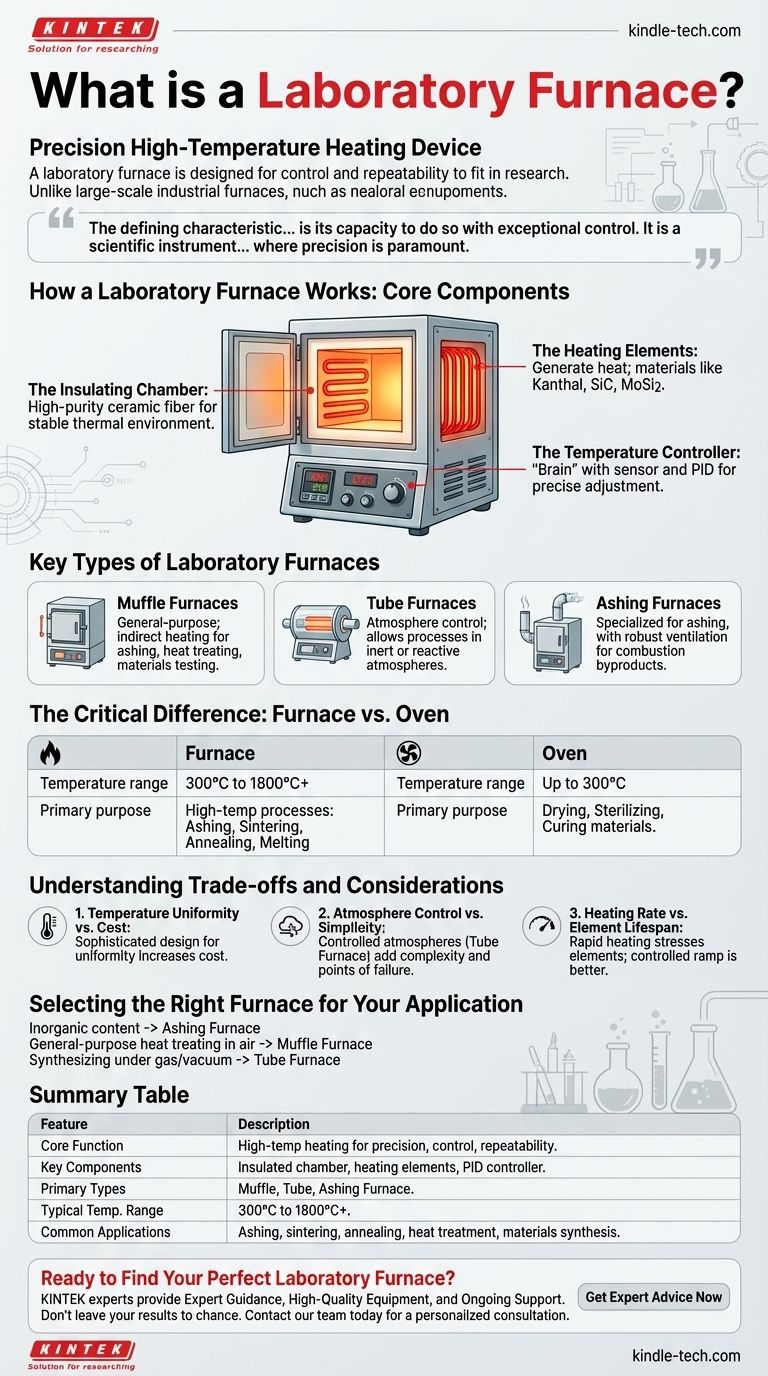

At its core, a laboratory furnace is a high-temperature heating device engineered for precision, control, and repeatability in a research or analytical setting. Unlike industrial furnaces built for large-scale production, lab furnaces are designed for smaller samples and applications where temperature accuracy and uniformity are critical for obtaining reliable data.

The defining characteristic of a laboratory furnace is not simply its ability to generate high heat, but its capacity to do so with exceptional control. It is a scientific instrument designed for analysis and synthesis, where precision is paramount.

How a Laboratory Furnace Works: Core Components

A laboratory furnace operates on a simple principle: converting electrical energy into heat within a thermally insulated chamber. This process is managed by three critical components working in unison.

The Insulating Chamber

The chamber is the heart of the furnace, constructed from refractory materials like high-purity ceramic fiber or firebricks. This heavy insulation is crucial for reaching high temperatures efficiently and, just as importantly, maintaining a stable and uniform thermal environment for the sample.

The Heating Elements

Heating elements are responsible for generating the heat. They are typically made from high-resistance alloys like Kanthal (iron-chromium-aluminum) or more advanced materials like silicon carbide (SiC) and molybdenum disilicide (MoSi2) for higher temperature applications. When an electric current passes through them, their resistance causes them to heat up intensely.

The Temperature Controller

This is the furnace's brain. A sensor, typically a thermocouple, constantly measures the internal temperature and sends that data to a PID (Proportional-Integral-Derivative) controller. The controller compares the actual temperature to the user's setpoint and precisely adjusts the power sent to the heating elements to maintain the desired temperature with minimal fluctuation.

Key Types of Laboratory Furnaces

While all lab furnaces share the same basic components, they are specialized for different tasks.

Muffle Furnaces

The muffle furnace is the general-purpose workhorse of the lab. The heating elements are located outside the primary chamber, heating the sample indirectly. This protects the elements from corrosive fumes and prevents sample contamination, making it ideal for ashing, heat treating, and general materials testing.

Tube Furnaces

Tube furnaces feature a cylindrical chamber, typically made of ceramic or quartz, through which a tube containing the sample is placed. Their primary advantage is atmosphere control. They can be sealed and connected to gas or vacuum systems, allowing for processes in inert (e.g., argon) or reactive atmospheres.

Ashing Furnaces

Ashing furnaces are a specialized type of muffle furnace optimized for determining the non-combustible "ash" content of a material. They are designed with robust ventilation systems to safely exhaust the large volume of smoke and fumes produced during the combustion process.

The Critical Difference: Furnace vs. Oven

The terms are often confused, but their functions are distinct. The primary differences come down to temperature and purpose.

Temperature Range

A laboratory oven typically operates at temperatures up to 300°C (approx. 572°F). A laboratory furnace starts where an oven leaves off, operating from around 300°C up to 1800°C (approx. 3272°F) or even higher.

Primary Purpose

Ovens are used for drying, sterilizing, and curing materials. Furnaces are used for high-temperature processes that fundamentally change a material's properties, such as ashing, sintering, annealing, melting, or calcination.

Understanding the Trade-offs and Considerations

Choosing or using a furnace involves balancing several key factors.

Temperature Uniformity vs. Cost

Achieving excellent temperature uniformity across the entire chamber requires sophisticated design, multiple heating zones, and advanced controllers. This significantly increases the cost of the unit. For less sensitive applications, a furnace with lower uniformity may be a perfectly acceptable, cost-effective solution.

Atmosphere Control vs. Simplicity

A standard muffle furnace operating in ambient air is simple and reliable. Introducing the capability for vacuum or controlled gas atmospheres, as seen in tube furnaces, adds complexity, requires more operator skill, and introduces more potential points of failure (e.g., seals and gas lines).

Heating Rate vs. Element Lifespan

While rapid heating is often desirable, it places significant thermal stress on the heating elements. Aggressive heating and cooling cycles can shorten their operational life. A controlled, slower ramp rate is often better for the long-term health of the furnace.

Selecting the Right Furnace for Your Application

Your choice depends entirely on the process you need to perform.

- If your primary focus is determining the inorganic content of a sample: You need an ashing furnace with excellent ventilation to handle the combustion byproducts safely.

- If your primary focus is general-purpose heat treating or materials analysis in air: A standard muffle furnace is your most versatile and cost-effective choice.

- If your primary focus is synthesizing materials under a specific gas or vacuum: A tube furnace is the essential instrument for creating a controlled processing atmosphere.

Understanding these core principles allows you to select not just a heating device, but the precise instrument your research demands.

Summary Table:

| Feature | Description |

|---|---|

| Core Function | High-temperature heating device for precision, control, and repeatability. |

| Key Components | Insulated chamber, heating elements, PID temperature controller. |

| Primary Types | Muffle Furnace, Tube Furnace, Ashing Furnace. |

| Typical Temp. Range | 300°C to 1800°C+ (significantly higher than lab ovens). |

| Common Applications | Ashing, sintering, annealing, heat treatment, materials synthesis. |

Ready to Find Your Perfect Laboratory Furnace?

Selecting the right furnace is critical for the success and reliability of your research. The experts at KINTEK are here to help you navigate the options.

We provide:

- Expert Guidance: We'll help you choose the ideal furnace (Muffle, Tube, or Ashing) based on your specific application, temperature, and atmosphere requirements.

- High-Quality Equipment: KINTEK specializes in durable, precise lab furnaces and consumables designed for accurate results.

- Ongoing Support: From installation to maintenance, we ensure your lab equipment performs at its best.

Don't leave your results to chance. Contact our team today for a personalized consultation and let KINTEK be your partner in precision.

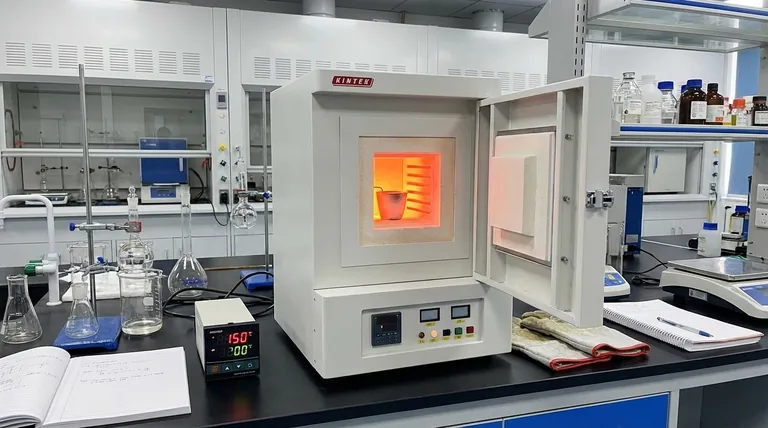

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does the discharge effect of a DC pulse power supply affect SPS nickel-based alloys? Achieve Rapid Densification

- Why is a vacuum drying oven used for GNPs-Cu/Ti6Al4V powders? Protect Reactive Metals from Oxidation

- Which type of brazing is done in a vacuum? Achieve Clean, Strong Joints with Vacuum Brazing

- What is pressureless sintering? Achieve Complex Shapes and High Purity Without External Pressure

- How do high-precision laboratory furnaces ensure the validity of experiments in nuclear simulation? ±1 K Stability

- What is the heating rate during heat treatment? Master the Key to Material Integrity

- What is a calciner in chemistry? A Guide to High-Temperature Material Transformation

- What is the temperature of debinding? A Guide to Mastering the Thermal Profile for MIM/CIM