While there is no standard process called "low power chemical vapor deposition," the term you are likely looking for is Low-Pressure Chemical Vapor Deposition (LPCVD). This is a crucial manufacturing technique where thin, high-performance films are created by introducing reactive gases into a chamber at very low pressures and high temperatures, causing a chemical reaction on a target substrate.

Low-Pressure Chemical Vapor Deposition (LPCVD) is not about reducing energy consumption; it is a specialized method that leverages a vacuum environment to produce exceptionally pure and uniform coatings, which is critical for manufacturing high-performance electronics and durable industrial parts.

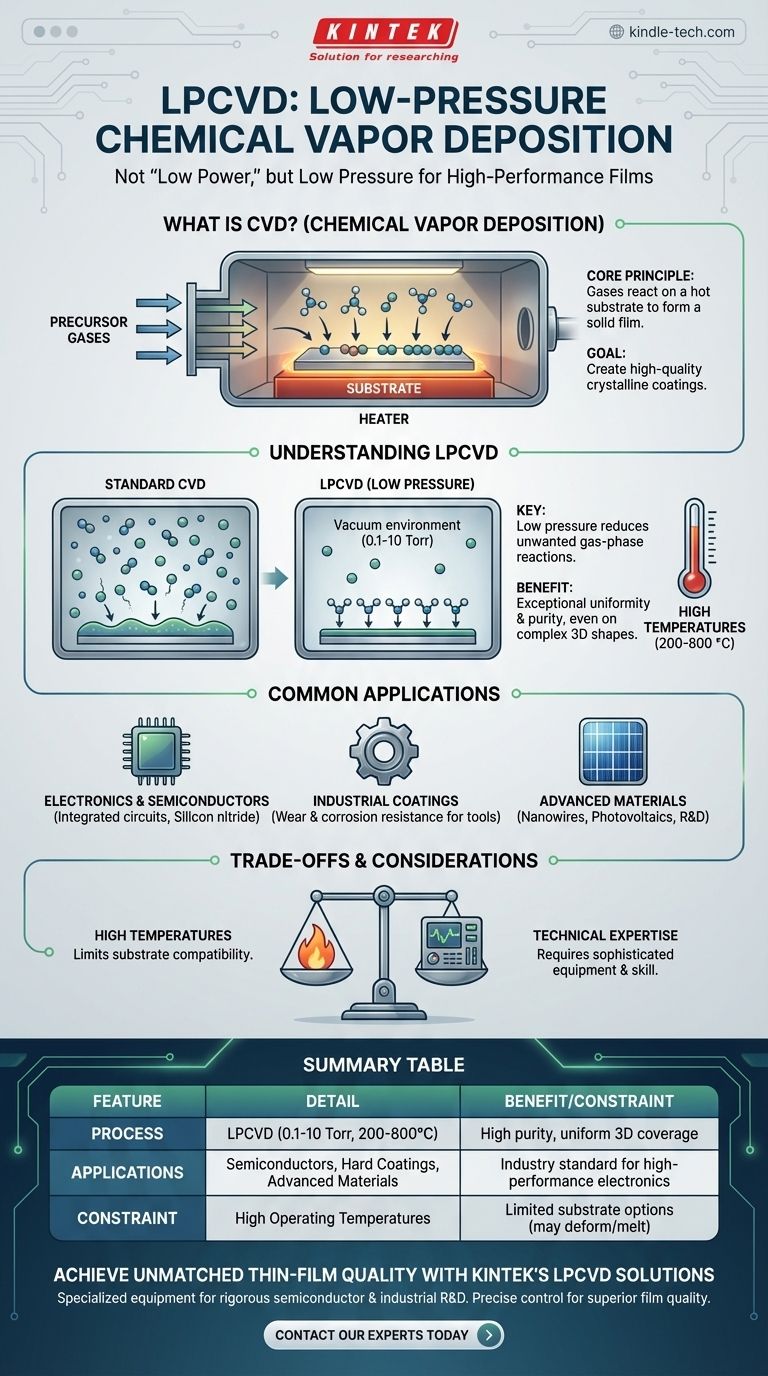

What is Chemical Vapor Deposition (CVD)?

The Core Principle: Precursor Gases on a Hot Surface

Chemical Vapor Deposition is a process for depositing a thin layer of solid material onto a surface, known as a substrate.

It works by placing the substrate in a reaction chamber and introducing one or more volatile precursor gases. Under controlled conditions, these gases react or decompose on the hot substrate's surface, leaving behind the desired solid film.

The Goal: Building High-Performance Films

The primary purpose of CVD is to grow high-quality, high-performance crystalline structures and coatings.

This method is incredibly versatile, used to create thin films of metallic, ceramic, or semiconducting materials on substrates like glass, metal, and other ceramics.

Understanding Low-Pressure CVD (LPCVD)

The Role of Low Pressure

LPCVD is a specific type of CVD that takes place in a vacuum, at pressures between 0.1 and 10 Torr.

Operating at low pressure reduces unwanted gas-phase reactions. This ensures that the chemical reactions happen primarily on the substrate's surface, not in the space around it.

The Impact on Film Quality

The vacuum environment is the key to LPCVD's success. By minimizing gas-phase reactions, the process yields films with excellent uniformity and purity.

This control allows for consistent coating thickness even over complex, three-dimensional shapes, which is difficult to achieve with other methods.

Key Operating Conditions

LPCVD processes typically require high temperatures, often ranging from 200 to 800 °C.

The combination of low pressure and high temperature, along with precise control over gas flow, dictates the final properties of the deposited film.

Common Applications of LPCVD

In Electronics and Semiconductors

LPCVD is fundamental to the microelectronics industry. It is used to deposit the thin films of silicon nitride, polysilicon, and other materials that form the building blocks of integrated circuits.

For Industrial Coatings

The process is also used to apply hard, durable coatings to industrial tools and components. These coatings increase resistance to wear and corrosion, significantly extending the life of the parts.

In Advanced Materials

Beyond traditional uses, LPCVD is employed in cutting-edge research and manufacturing to grow materials like carbon nanotubes and gallium nitride (GaN) nanowires, as well as photovoltaic materials for thin-film solar cells.

Understanding the Trade-offs

The Need for High Temperatures

The high operating temperatures required for LPCVD can be a significant constraint. This limits the types of substrate materials that can be used, as some may not withstand the heat without deforming or melting.

Requirement for Technical Expertise

LPCVD is not a simple process. It requires sophisticated equipment and a high level of skill to manage the precise control of pressure, temperature, and gas chemistry needed to achieve consistent, high-quality results.

Making the Right Choice for Your Goal

- If your primary focus is exceptional film uniformity and purity for electronics: LPCVD is the industry standard and the superior choice for depositing films on semiconductor wafers.

- If your primary focus is coating complex 3D shapes consistently: The low-pressure environment of LPCVD makes it ideal for ensuring uniform coverage over intricate geometries.

- If your substrate is sensitive to high temperatures: You may need to explore alternative deposition methods, such as Plasma-Enhanced CVD (PECVD), which operates at lower temperatures.

Ultimately, choosing LPCVD depends on balancing the need for superior film quality against the constraints of its high-temperature operating window.

Summary Table:

| Feature | Detail |

|---|---|

| Process Name | Low-Pressure Chemical Vapor Deposition (LPCVD) |

| Key Characteristic | Operates under vacuum (0.1-10 Torr) at high temperatures (200-800°C) |

| Primary Benefit | Exceptional film uniformity and purity, ideal for 3D shapes |

| Common Applications | Semiconductor manufacturing, hard coatings, advanced materials like GaN nanowires |

| Main Constraint | High temperature limits substrate compatibility |

Achieve Unmatched Thin-Film Quality with KINTEK's LPCVD Solutions

Struggling to deposit ultra-pure, uniform coatings on complex components? KINTEK specializes in advanced lab equipment, including LPCVD systems, designed to meet the rigorous demands of semiconductor manufacturing and industrial R&D. Our expertise ensures you get the precise temperature and pressure control necessary for superior film quality, every time.

Ready to enhance your deposition process? Contact our experts today to discuss how our LPCVD technology can drive your innovation forward.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor