In simple terms, "machine press plywood" is not a special type of plywood but rather a description of the standard industrial method used to manufacture virtually all modern plywood. The term refers to the process where thin wood veneers, coated with adhesive, are fused together under immense hydraulic pressure and high heat inside a large machine press.

The term "machine press" describes the how, not the what. Understanding this process is the key to looking past the name and focusing on the factors that truly define plywood's quality: its grade, adhesive, and core construction.

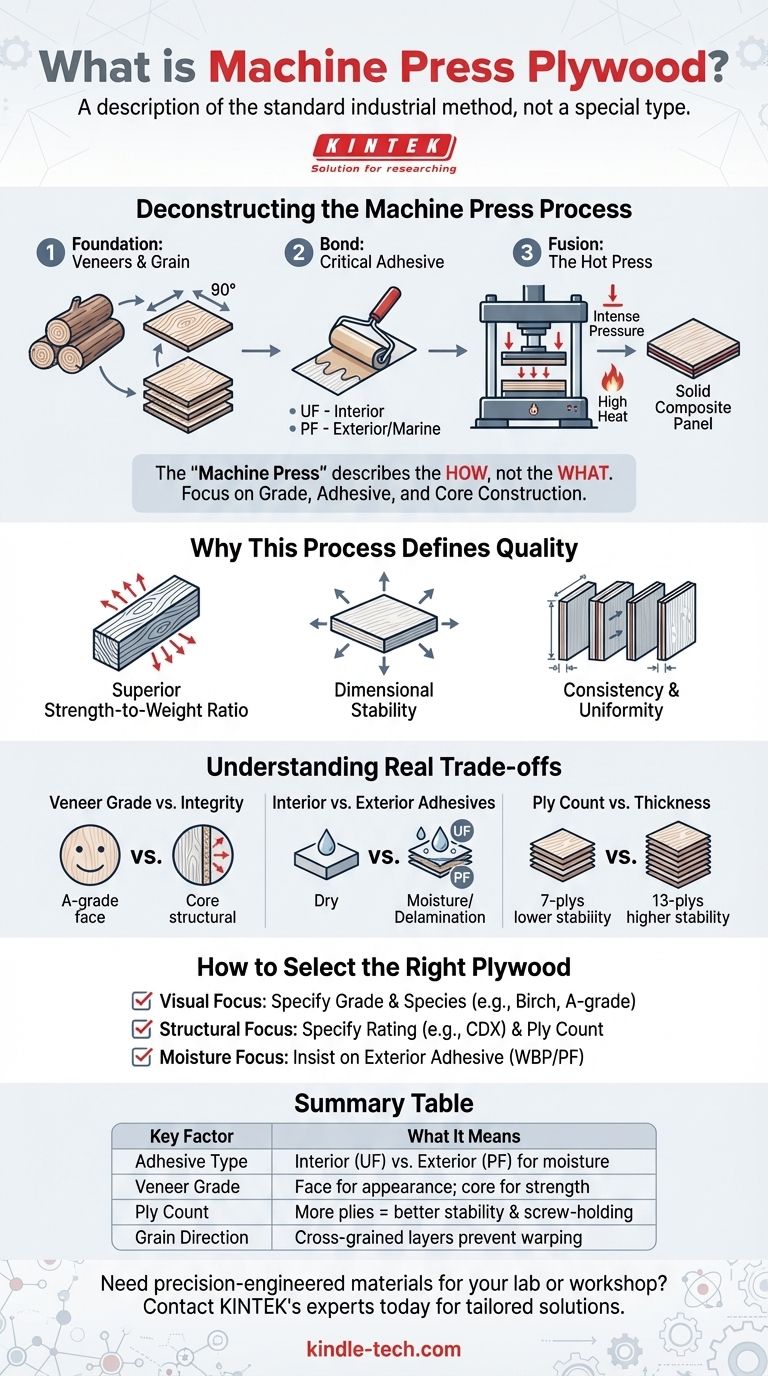

Deconstructing the Machine Press Process

To understand the final product, you must first understand how it's made. Every sheet of plywood is an engineered assembly, and the machine press is the heart of that engineering.

The Foundation: Veneers and Grain Direction

Plywood begins as thin sheets of wood called veneers, which are peeled from a log on a large lathe.

The defining characteristic of plywood is that these veneers are stacked with the grain direction of each layer oriented at a 90-degree angle to the one below it. This cross-graining is what gives plywood its strength and resistance to expansion or contraction.

The Bond: The Critical Adhesive Layer

Before being stacked, each veneer is coated with a powerful adhesive. The type of adhesive used is one of the most critical factors in the plywood's final performance.

Common adhesives include urea-formaldehyde (UF) for interior use and the more durable, water-resistant phenol-formaldehyde (PF) for exterior or marine applications.

The Fusion: The Hot Press

This is the "machine press" stage. The stack of adhesive-coated, cross-grained veneers is loaded into a massive hydraulic hot press.

This machine applies two critical forces simultaneously:

- Intense Pressure: This eliminates gaps between layers and ensures a tight, uniform bond.

- High Heat: This cures the adhesive, creating a permanent, thermoset bond that is stronger than the wood itself.

The result is no longer a simple stack of wood sheets but a single, solid, and incredibly stable composite panel.

Why This Process Defines Plywood Quality

The machine press process is what transforms flimsy veneers into one of the most versatile building materials available. It is directly responsible for plywood's most valued characteristics.

Superior Strength-to-Weight Ratio

The combination of cross-grained veneers and a pressure-cured adhesive bond distributes stress across the entire panel. This makes plywood significantly stronger and more rigid than a solid piece of wood of the same dimensions and weight.

Dimensional Stability

Solid wood naturally expands and contracts with changes in humidity, leading to warping and cracking. Plywood's cross-grained structure restricts this movement, making the panel far more dimensionally stable and reliable in various environments.

Consistency and Uniformity

The machine press process guarantees a consistent thickness and flatness across the entire sheet, which is essential for construction, cabinetry, and furniture making where precise dimensions are non-negotiable.

Understanding the Real Trade-offs

Focusing on the term "machine press" can distract from the variables that actually determine a panel's suitability for a job. The quality of the press is assumed; the quality of the ingredients is what you must scrutinize.

Veneer Grade vs. Structural Integrity

A-grade face veneers provide a beautiful, smooth surface perfect for finishing but have no bearing on the panel's structural strength. For structural applications, the quality of the core veneers and the adhesive type are far more important than the appearance of the face.

Interior vs. Exterior Adhesives

Using an interior-grade plywood (with UF glue) in an exterior or damp application is a common and costly mistake. The adhesive will break down when exposed to moisture, causing the plies to separate, a process known as delamination.

Ply Count vs. Panel Thickness

For a given thickness, a panel with more, thinner plies will generally be more stable and have better screw-holding properties than one with fewer, thicker plies. For example, a 3/4" panel with 13 plies is often considered superior to one with only 7.

How to Select the Right Plywood

Instead of asking for "machine press plywood," focus on specifying the characteristics you need to achieve your goal.

- If your primary focus is visual appearance: Ask for an A or B-grade face veneer and specify the wood species (e.g., Birch, Oak) for your cabinetry or furniture project.

- If your primary focus is structural strength: Specify the structural rating (e.g., CDX for sheathing) and prioritize a higher ply count over face appearance.

- If your primary focus is moisture resistance: Insist on plywood made with an exterior-grade or waterproof adhesive (WBP - Water Boil Proof), typically phenol-formaldehyde.

By understanding these core components, you can confidently select the precise panel engineered for your specific application.

Summary Table:

| Key Factor | What It Means for Your Project |

|---|---|

| Adhesive Type | Interior (UF) for dry areas; Exterior (PF) for moisture resistance. |

| Veneer Grade | A-grade for appearance; core veneers for structural strength. |

| Ply Count | More plies (e.g., 13-ply) = better stability and screw-holding power. |

| Grain Direction | Cross-grained layers prevent warping and add strength. |

Need precision-engineered materials for your lab or workshop? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to demanding environments. Whether you're building custom lab furniture, storage solutions, or require stable substrates for sensitive equipment, understanding material properties is key. Let our experts help you select the right materials for durability and performance. Reach out to our team today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production