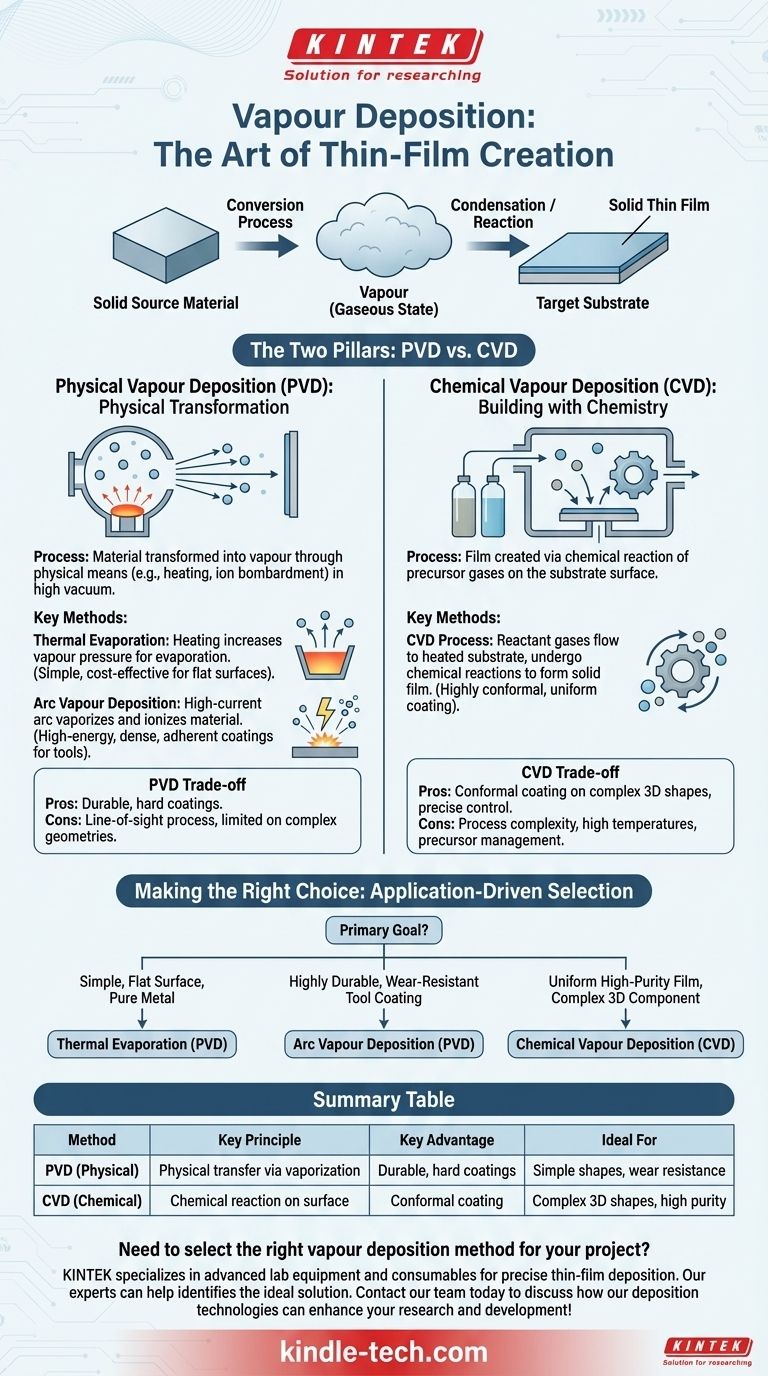

In essence, vapour deposition is a family of advanced manufacturing techniques used to apply an exceptionally thin film of material onto a surface, known as a substrate. The process involves taking a solid source material, converting it into a gaseous state (a vapour), and then allowing it to condense or react to form a solid layer on the target object. The core difference between methods lies in how that vapour is created and deposited—either through physical processes or chemical reactions.

The primary distinction in vapour deposition is between Physical Vapour Deposition (PVD) and Chemical Vapour Deposition (CVD). PVD physically transfers material from a source to the substrate, while CVD uses precursor gases that chemically react at the substrate to create an entirely new solid film.

The Two Pillars of Vapour Deposition: PVD vs. CVD

Understanding the fundamental difference between physical and chemical methods is the first step to mastering this topic. The method chosen dictates the properties of the final coating.

Physical Vapour Deposition (PVD): A Physical Transformation

PVD encompasses a group of processes where a material is transformed into a vapour through purely physical means, such as heating or bombardment with ions.

These processes occur under a high vacuum, allowing vapour particles to travel directly from the source to the substrate with few collisions. This is often described as a "line-of-sight" process.

Chemical Vapour Deposition (CVD): Building with Chemistry

CVD creates a film through a chemical reaction on the substrate's surface. Precursor gases are introduced into a reaction chamber, which then decompose or react near the heated substrate.

This chemical creation of the film is not a line-of-sight process. It allows the gases to flow around complex objects, resulting in a highly conformal coating that uniformly covers intricate shapes.

A Closer Look at Deposition Methods

Within PVD and CVD, several specific techniques exist, each with unique mechanisms and applications.

Thermal Evaporation: The Simplest PVD Method

This process works by heating a source material inside a high-vacuum chamber.

The heat, typically between 250°C and 350°C, increases the material's vapour pressure until it evaporates, turning from a solid into a gas. This vapour stream then travels through the vacuum and condenses on the cooler substrate, forming the film.

Arc Vapour Deposition: A High-Energy PVD Method

Arc Vapour Deposition uses a high-current, low-voltage electric arc to vaporize material from a solid target.

The key feature of this method is that a significant portion of the vaporized atoms become ionized (they gain an electric charge). This high-energy, ionized flux is accelerated toward the substrate, resulting in an exceptionally dense and adherent coating.

The CVD Process: A Step-by-Step Reaction

The CVD process is a carefully controlled chemical sequence.

First, reactant gases are transported into a chamber. These gases flow toward the hot substrate, where they undergo chemical reactions on the surface.

This heterogeneous surface reaction leads to the formation of the solid film. Finally, any gaseous by-products from the reaction are desorbed from the surface and removed from the chamber.

Understanding the Key Trade-offs

Neither PVD nor CVD is universally superior; the choice depends entirely on the desired outcome and application constraints.

PVD: Durability vs. Coverage

PVD methods are valued for producing extremely hard and durable coatings, especially high-energy processes like arc deposition.

However, because PVD is largely a line-of-sight technique, it can be challenging to achieve a uniform coating on components with complex geometries, such as internal surfaces or sharp corners.

CVD: Conformality vs. Complexity

The greatest strength of CVD is its ability to produce a uniform, "wrap-around" film on even the most complex 3D shapes. It also allows for precise control over the film's chemical composition and crystal structure.

The trade-off is process complexity. CVD often requires higher temperatures and involves managing precursor chemicals and their volatile by-products, which can be challenging and expensive.

Making the Right Choice for Your Goal

Selecting the correct method requires a clear understanding of your project's primary goal.

- If your primary focus is coating a simple, flat surface with a pure metal: Thermal Evaporation (PVD) is often the most straightforward and cost-effective method.

- If you need a highly durable, dense, and wear-resistant coating on a tool: Arc Vapour Deposition (PVD) is superior due to the high-energy, ionized vapour it creates.

- If you must apply a uniform, high-purity film over a complex 3D component: Chemical Vapour Deposition (CVD) is the ideal choice because the chemical reaction naturally coats all exposed surfaces.

Ultimately, understanding the fundamental difference between physical transport and chemical creation is the key to selecting the right vapour deposition technique for your specific material and application.

Summary Table:

| Method | Key Principle | Key Advantage | Ideal For |

|---|---|---|---|

| PVD (Physical) | Physical transfer of material via vaporization | Durable, hard coatings | Simple shapes, wear resistance |

| CVD (Chemical) | Chemical reaction on substrate surface | Conformal coating on complex 3D shapes | Intricate components, high purity |

Need to select the right vapour deposition method for your project?

KINTEK specializes in providing advanced lab equipment and consumables for precise thin-film deposition. Whether you require the durability of PVD or the conformal coverage of CVD, our experts can help you identify the ideal solution for your laboratory's specific materials and application needs.

Contact our team today to discuss how our deposition technologies can enhance your research and development!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method