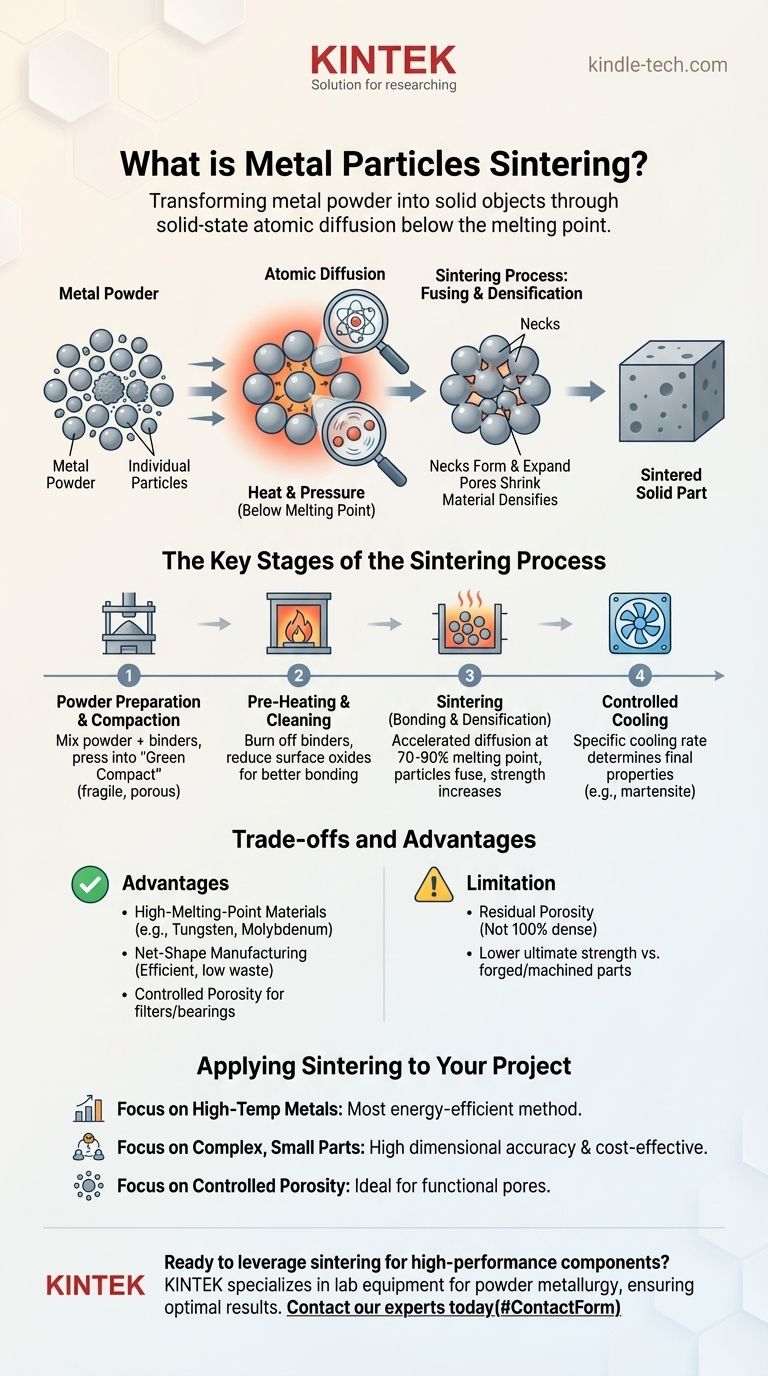

In essence, metal particle sintering is a manufacturing process that transforms metal powder into a solid, dense object using heat and pressure. Crucially, this is achieved at a temperature below the material's melting point, causing the individual particles to fuse together without ever turning into a liquid.

Sintering is fundamentally about encouraging solid-state atomic diffusion. By applying heat and pressure, you give metal atoms the energy to move across the boundaries of individual powder particles, bonding them into a single, cohesive mass and reducing the empty space between them.

The Core Principle: Atomic Diffusion Without Melting

What Drives the Process?

Sintering works because atoms in a solid are not static; they vibrate and can move. Heat increases this atomic movement.

When metal powder is heated, atoms on the surface of each particle become mobile enough to migrate across the boundaries to an adjacent particle. This movement is called atomic diffusion.

Fusing Particles into a Solid

As atoms diffuse, the contact points between particles grow into "necks." These necks expand until the boundaries between the original particles disappear, effectively fusing them.

This process reduces the overall surface area and minimizes the system's energy, resulting in a denser, stronger, and more stable final part. It is similar to how a cluster of soap bubbles will merge to form larger bubbles to reduce total surface tension.

The Key Stages of the Sintering Process

Sintering is not a single event but a carefully controlled, multi-stage thermal process. While specifics vary, the journey from powder to part generally follows these steps.

Stage 1: Powder Preparation and Compaction

Before heating, the base metal powder is often mixed with other elements, such as alloys or lubricants. This homogenous mixture is then pressed into a mold under high pressure.

This initial pressing forms a fragile, precisely shaped part known as a "green compact" or billet. It has the desired shape but lacks strength and is still highly porous.

Stage 2: Pre-Heating and Cleaning

The green compact is heated in a controlled-atmosphere furnace. The initial phase of heating is designed to burn off any lubricants or binders used during compaction.

This stage also often involves reducing surface oxides from the metal particles. Clean, oxide-free surfaces are critical for enabling effective atomic diffusion and strong bonds in the next stage.

Stage 3: Sintering (Bonding and Densification)

This is the core of the process. The temperature is raised to the sintering point, typically 70-90% of the material's absolute melting temperature.

At this temperature, atomic diffusion accelerates dramatically. Particles fuse, pores shrink or are eliminated, and the material undergoes significant densification, increasing its strength and hardness.

Stage 4: Controlled Cooling

After holding at the sintering temperature for a set time, the part is cooled in a controlled manner. The cooling rate can be manipulated to achieve specific final properties, such as forming hard martensitic structures in steel-based components.

Understanding the Trade-offs and Advantages

Sintering is a powerful technique, but it's not a universal solution. Its selection depends on a clear understanding of its benefits and limitations.

Primary Advantage: High-Melting-Point Materials

Sintering is the go-to method for materials with extremely high melting points, such as tungsten and molybdenum. Melting and casting these materials would be incredibly energy-intensive and difficult.

Primary Advantage: Net-Shape Manufacturing

The process allows for the creation of complex parts to their final (or "net") shape with very little material waste or need for subsequent machining. This makes it highly efficient for mass production.

Key Limitation: Residual Porosity

It is very difficult to achieve 100% density through sintering alone. There will almost always be some small amount of residual porosity (empty space) left in the final part.

This means a sintered component may not have the same ultimate strength as a part forged or machined from a solid, fully dense billet of the same material.

How to Apply This to Your Project

The decision to use sintering is driven by your material choice, part complexity, and performance requirements.

- If your primary focus is working with high-temperature metals: Sintering is often the most practical and energy-efficient method available for materials like tungsten.

- If your primary focus is mass-producing complex, small parts: Powder metallurgy and sintering offer excellent dimensional accuracy and minimal material waste, making it highly cost-effective.

- If your primary focus is creating parts with controlled porosity: Sintering is the ideal process for manufacturing products like metal filters or self-lubricating bearings, where the pores are a functional feature.

By understanding sintering as a process of atomic bonding, you can better leverage its unique capabilities for your specific manufacturing goals.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Fusing metal powder using heat and pressure below melting point |

| Mechanism | Atomic diffusion forms necks between particles, reducing porosity |

| Key Stages | Powder compaction → Pre-heating/cleaning → Sintering → Controlled cooling |

| Best For | High-melting-point metals (tungsten, molybdenum), net-shape parts, controlled porosity |

| Limitation | Residual porosity may limit ultimate strength vs. fully dense materials |

Ready to leverage sintering for your high-performance metal components? KINTEK specializes in providing the precise lab equipment and consumables needed for advanced powder metallurgy processes. Whether you're working with tungsten, molybdenum, or other alloys, our solutions ensure optimal temperature control and atmosphere management for superior sintering results. Contact our experts today to discuss how we can support your laboratory's sintering projects!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum hot pressing sintering furnace facilitate the high densification of Al-30%Sc alloys?

- What are the key functions of a vacuum hot press sintering furnace? Produce High-Density UN Ceramic Pellets

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.