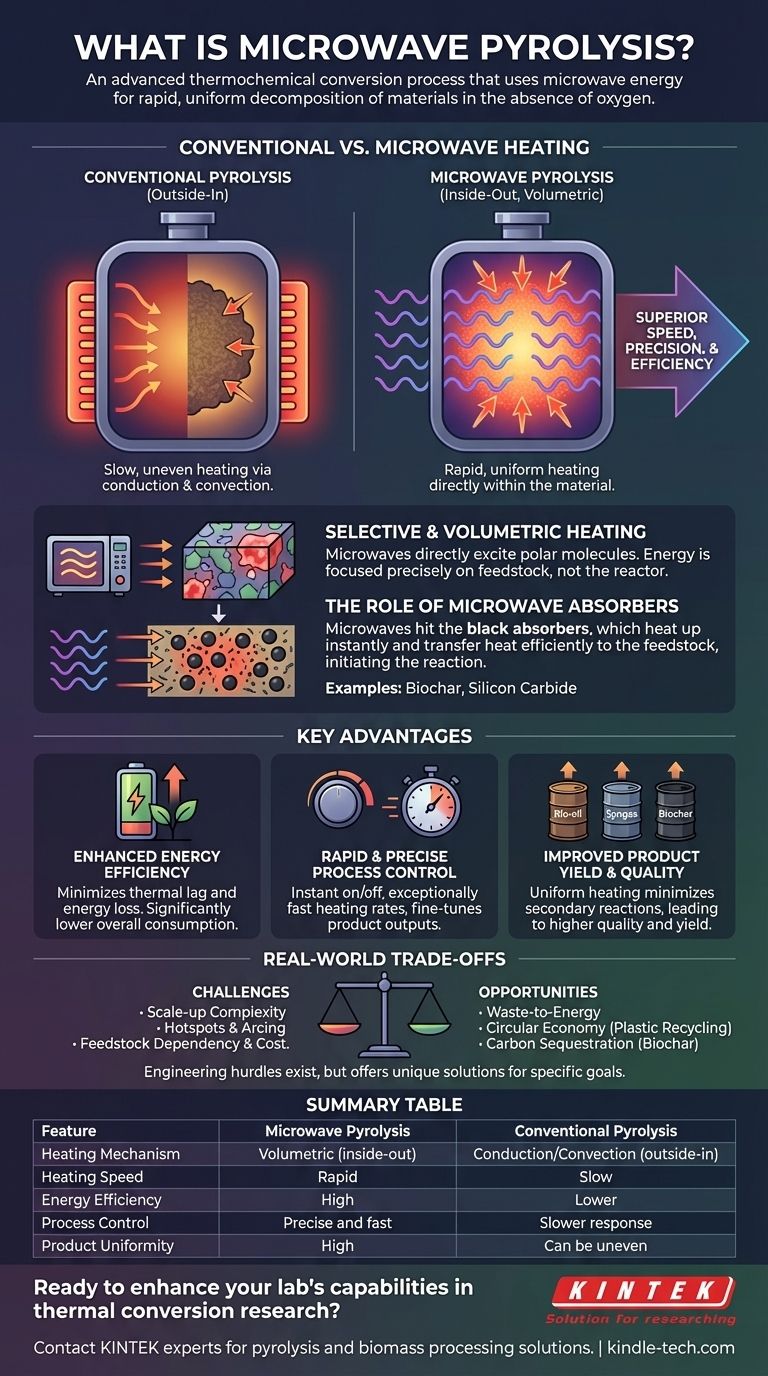

In essence, microwave pyrolysis is an advanced thermochemical conversion process that uses microwave energy to heat and decompose materials in the absence of oxygen. Unlike traditional pyrolysis which heats materials from the outside-in, this method uses microwaves to heat the material directly and volumetrically, leading to rapid and more uniform decomposition into valuable products like oil, gas, and char.

At its core, the critical distinction of microwave pyrolysis is not simply the heat source, but its ability to deliver energy directly to the target material. This offers a level of speed, precision, and efficiency that conventional heating methods struggle to match.

How Microwave Pyrolysis Fundamentally Differs

To grasp the significance of this technology, it's essential to understand how it departs from conventional methods. The difference lies in the fundamental mechanism of energy transfer.

Conventional vs. Microwave Heating

Traditional pyrolysis works like a conventional oven. It heats the outside of a reactor, and that heat slowly transfers inward to the material (conduction and convection). This process is slow and often results in uneven heating.

Microwave pyrolysis works like a microwave oven. It uses electromagnetic radiation to excite polar molecules within the material itself, generating heat from the inside-out. This is known as volumetric heating.

Selective and Volumetric Heating

Microwaves do not heat all materials equally. They primarily interact with materials that have good dielectric properties, causing them to heat up rapidly and uniformly throughout their entire volume.

This selective nature means the energy is focused precisely where it's needed—on the feedstock—rather than being wasted on heating the reactor vessel and surrounding air.

The Role of Microwave Absorbers

Some target materials, like certain plastics or dry biomass, do not absorb microwave energy well on their own.

In these cases, a highly receptive material, known as a microwave absorber (like biochar or silicon carbide), is mixed with the feedstock. This absorber heats up rapidly and transfers that heat efficiently to the target material, initiating the pyrolysis reaction.

The Key Advantages of This Approach

The unique heating mechanism of microwave pyrolysis translates into several distinct operational advantages that are driving its adoption in research and industry.

Enhanced Energy Efficiency

By delivering energy directly to the feedstock, the process minimizes thermal lag and energy loss to the environment. This results in significantly lower overall energy consumption compared to conventional pyrolysis systems of similar scale.

Rapid and Precise Process Control

Microwave generators can be turned on and off almost instantly. This allows for exceptionally fast heating rates and precise temperature control, enabling operators to fine-tune the reaction to favor the production of specific outputs (e.g., more oil or more gas).

Improved Product Yield and Quality

The rapid and uniform heating minimizes unwanted secondary reactions that can degrade the quality of the products. This often leads to a higher yield of valuable liquid bio-oil (also called pyrolysis oil) and a more consistent quality of syngas and solid biochar.

Understanding the Real-World Trade-offs

No technology is without its challenges. While promising, microwave pyrolysis presents unique engineering hurdles that must be addressed for widespread commercial application.

The Challenge of Scale

Translating a process from a small lab-scale batch reactor to a large, continuous industrial plant is complex. Ensuring uniform microwave distribution in a large volume to prevent uneven processing is a significant engineering challenge.

Managing Hotspots and Arcing

Non-uniform microwave fields or impurities in the feedstock can lead to hotspots—areas of intense, uncontrolled heating. Furthermore, the presence of metallic contaminants can cause electrical arcing, which can damage equipment and halt the process.

Feedstock Dependency and Cost

The effectiveness of the process is highly dependent on the feedstock's dielectric properties. The potential need for specialized microwave absorbers adds a layer of complexity and cost to the operation, and the initial capital cost for microwave generators can be higher than for conventional heaters.

Making the Right Choice for Your Goal

Microwave pyrolysis is not a one-size-fits-all solution, but a powerful tool for specific objectives in resource recovery and waste management.

- If your primary focus is waste-to-energy: Microwave pyrolysis offers a highly efficient pathway to convert low-value biomass or mixed plastics into energy-dense liquid fuels and combustible syngas.

- If your primary focus is a circular economy: This technology excels at the chemical recycling of complex plastics, breaking them down into valuable hydrocarbon feedstocks for creating new materials.

- If your primary focus is carbon sequestration: The process can be optimized to maximize the production of stable, high-carbon biochar, which can be used for soil amendment to lock away carbon for centuries.

This technology represents a sophisticated evolution in thermal processing, offering a more controlled and efficient route to transforming waste into value.

Summary Table:

| Feature | Microwave Pyrolysis | Conventional Pyrolysis |

|---|---|---|

| Heating Mechanism | Volumetric (inside-out) | Conduction/Convection (outside-in) |

| Heating Speed | Rapid | Slow |

| Energy Efficiency | High | Lower |

| Process Control | Precise and fast | Slower response |

| Product Uniformity | High | Can be uneven |

Ready to enhance your lab's capabilities in thermal conversion research? KINTEK specializes in advanced lab equipment for pyrolysis and biomass processing. Our solutions help researchers achieve precise, efficient results in waste-to-energy and circular economy projects. Contact our experts today to find the perfect system for your needs!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Lab-Scale Vacuum Induction Melting Furnace

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions