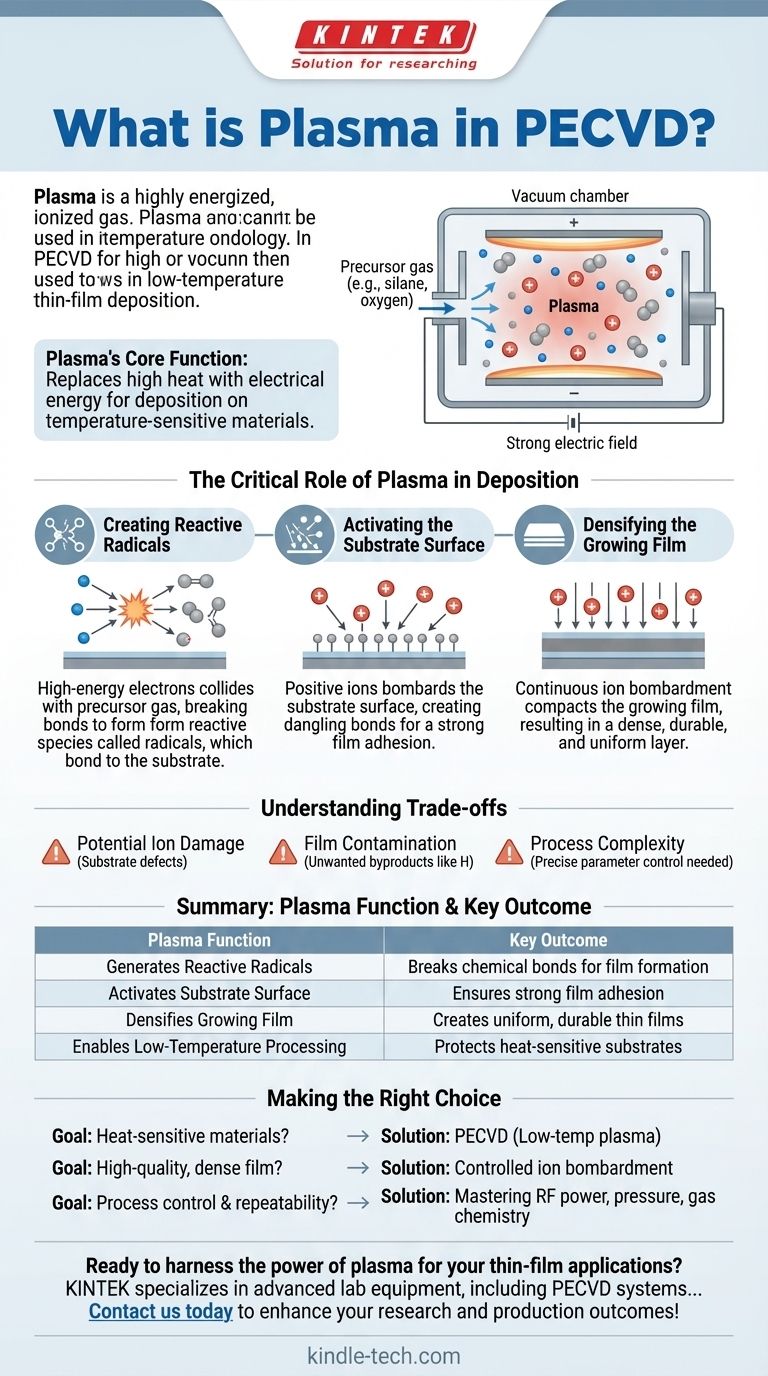

In the context of PECVD, plasma is a highly energized, ionized gas that serves as the primary engine for the thin-film deposition process. It is a mixture of electrons, charged ions, and neutral gas molecules, created by applying a strong electrical field to a precursor gas inside a vacuum chamber. This plasma provides the energy needed to break chemical bonds and drive reactions, enabling the creation of high-quality films at significantly lower temperatures than traditional methods.

The core function of plasma in PECVD is to replace high heat as the source of energy. This "enhancement" allows for the deposition of durable, thin films onto temperature-sensitive materials that would be damaged by conventional high-temperature processes.

How Plasma is Generated in the Chamber

To understand plasma's role, we must first understand how it is created within the PECVD system. The process is a controlled and precise application of energy to a gas.

The Basic Principle: Energizing a Gas

Plasma is generated by introducing a precursor gas (like silane or oxygen) into a low-pressure chamber. An electric field is then applied between two electrodes within this chamber.

This electrical energy excites the gas, stripping electrons from some of the atoms or molecules and creating a mixture of free electrons and positively charged ions, all while many atoms remain neutral. The result is the highly reactive state of matter known as plasma.

Common Power Sources

The electrical field is typically generated using one of several power sources, each with specific applications.

The most common method uses a radio frequency (RF) alternating current. Other methods include direct current (DC), mid-frequency (MF), or microwave power. The choice of power source influences the characteristics of the plasma and, consequently, the properties of the deposited film.

The Critical Role of Plasma in Deposition

The plasma is not just a power source; it is an active participant in the chemical deposition process. Its unique properties facilitate multiple crucial steps simultaneously.

Creating Reactive Radicals

The high-energy free electrons within the plasma collide with the neutral precursor gas molecules. These collisions are energetic enough to break chemical bonds, creating highly reactive species known as radicals.

These radicals are the primary building blocks for the new film. Being chemically unstable, they readily bond to the substrate surface to form the desired material layer.

Activating the Substrate Surface

Simultaneously, the positively charged ions from the plasma are accelerated by the electric field and bombard the surface of the substrate.

This ion bombardment is not destructive but rather an activation step. It creates dangling bonds—atomic-scale points on the surface that are highly receptive to bonding with the newly formed radicals. This ensures the film adheres strongly to the substrate.

Densifying the Growing Film

The ion bombardment continues as the film grows. This steady energy input helps to densify the film by knocking away any weakly bonded atoms or undesirable byproducts.

This action is akin to a microscopic tamping process, resulting in a film that is more uniform, dense, and durable than one grown without plasma enhancement.

Understanding the Trade-offs

While plasma enhancement is a powerful technique, it is essential to recognize its inherent complexities and potential downsides.

Potential for Ion Damage

The same ion bombardment that activates the surface and densifies the film can also cause damage if not properly controlled. For extremely sensitive substrates, excessive ion energy can create defects in the material's crystal structure, impacting its performance.

Film Contamination

The chemical reactions that create radicals can also produce unwanted byproducts. For example, in processes using silane (SiH₄), hydrogen atoms can become incorporated into the silicon film, which can affect its electrical or optical properties.

Process Complexity

PECVD systems are inherently more complex than simple thermal CVD reactors. Controlling the plasma requires precise management of power levels, frequency, gas pressure, and flow rates. Achieving consistent, high-quality results demands a deep understanding of these interrelated parameters.

Making the Right Choice for Your Goal

Understanding plasma's function allows you to leverage the PECVD process effectively for specific outcomes.

- If your primary focus is depositing on heat-sensitive materials (like polymers or certain semiconductors): PECVD's use of low-temperature plasma is the essential enabling technology for your application.

- If your primary focus is achieving a high-quality, dense film: The controlled ion bombardment from the plasma is a key mechanism for improving film structure and durability.

- If your primary focus is process control and repeatability: Mastering the relationship between RF power, pressure, and gas chemistry is critical to controlling plasma characteristics for consistent results.

Ultimately, grasping the role of plasma transforms your view of PECVD from a "black box" into a highly controllable and versatile engineering tool.

Summary Table:

| Plasma Function | Key Outcome |

|---|---|

| Generates Reactive Radicals | Breaks chemical bonds for film formation |

| Activates Substrate Surface | Ensures strong film adhesion |

| Densifies Growing Film | Creates uniform, durable thin films |

| Enables Low-Temperature Processing | Protects heat-sensitive substrates |

Ready to harness the power of plasma for your thin-film applications? KINTEK specializes in advanced lab equipment, including PECVD systems, to help you achieve precise, low-temperature deposition on sensitive materials. Our expertise ensures you get the right solution for high-quality, durable films with excellent process control. Contact us today to discuss your specific laboratory needs and discover how our solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vertical Laboratory Tube Furnace

People Also Ask

- What materials can be deposited using PECVD? Discover Versatile Low-Temperature Thin Films

- What is the process of PACVD coating? A Guide to Low-Temperature, High-Performance Thin Films

- What temperature is PECVD nitride? Optimize Your Silicon Nitride Film Properties

- What are the different types of plasma sources? A Guide to DC, RF, and Microwave Technologies

- What temperature does plasma deposition occur? Master Low-Temp Film Deposition for Sensitive Materials

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition