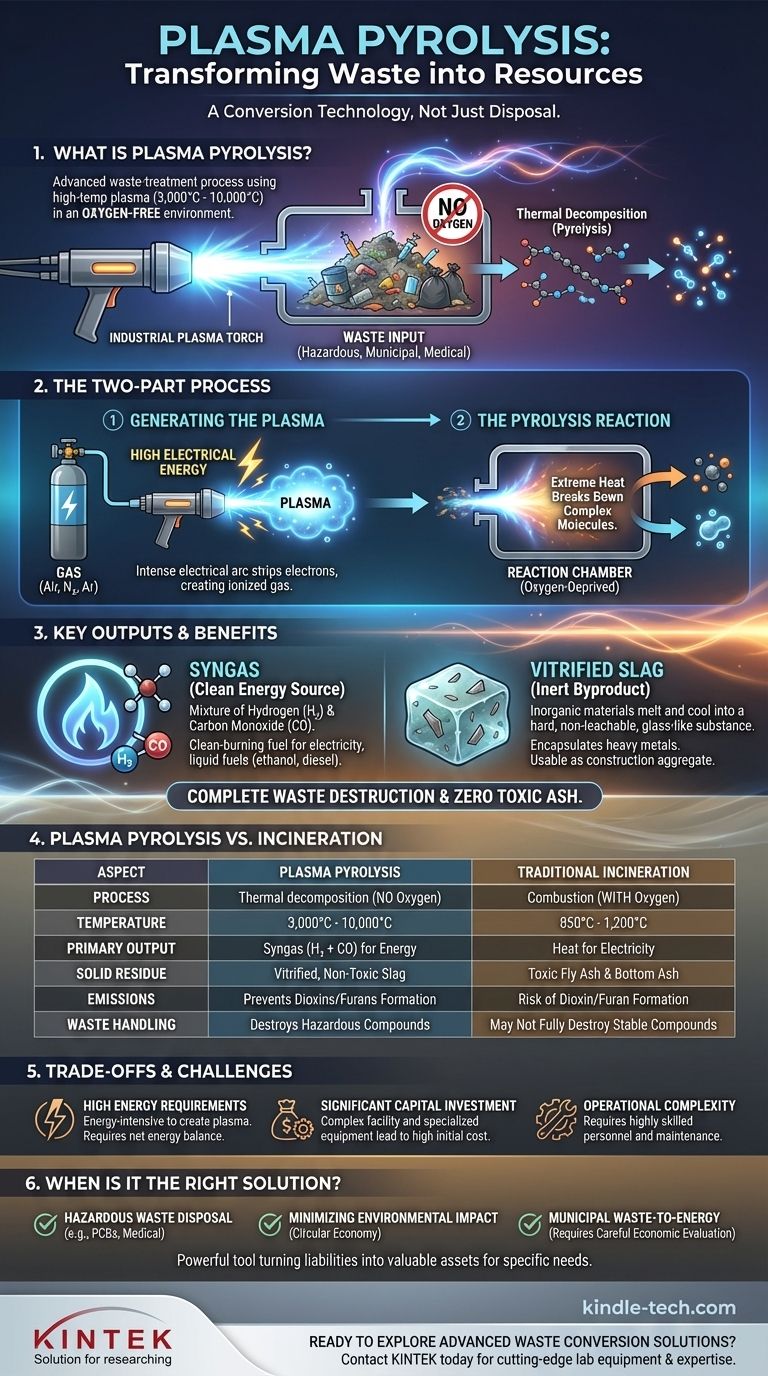

At its core, plasma pyrolysis is an advanced waste-treatment process that uses extremely high temperatures from a plasma torch to decompose waste material in an oxygen-free environment. Unlike burning (incineration), this process doesn't combust the waste; instead, it uses intense energy to break it down into its basic molecular components, converting it into a valuable fuel gas and a non-toxic solid residue.

The critical distinction to understand is that plasma pyrolysis is not simply a disposal method—it is a material conversion technology. It redefines "waste" as a raw material, using extreme heat to transform hazardous and complex materials into clean energy and inert, reusable solids.

How Plasma Pyrolysis Works: A Two-Part Process

The technology operates by combining two well-understood scientific principles: plasma generation and pyrolysis.

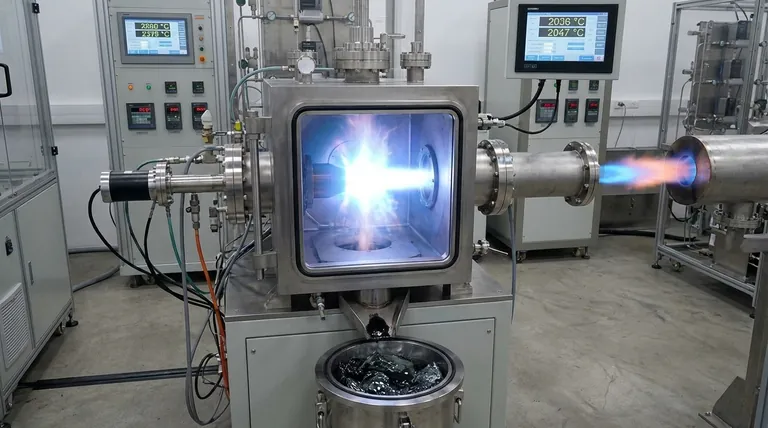

Part 1: Generating the Plasma

A plasma torch, or plasma arc, is the heart of the system. It works by passing a gas—such as air, nitrogen, or argon—through a powerful electric arc.

This intense electrical energy strips the electrons from the gas atoms, creating an ionized gas known as plasma. This plasma can reach temperatures between 3,000°C and 10,000°C (5,400°F to 18,000°F).

Part 2: The Pyrolysis Reaction

The waste material is fed into a sealed chamber that is deprived of oxygen. The plasma torch injects its intense heat into this chamber.

This extreme temperature causes pyrolysis, the thermal decomposition of the material. The long, complex organic molecules in the waste are violently broken apart into their simplest constituent elements and small molecules.

Key Outputs: Transforming Waste into Resources

The output of plasma pyrolysis is fundamentally different from that of incineration, yielding valuable resources instead of problematic ash.

Syngas: A Clean Energy Source

The primary output is a mixture of hydrogen (H₂) and carbon monoxide (CO), known as synthesis gas or syngas.

This gas is a clean-burning fuel. It can be used in gas engines or turbines to generate electricity or can be further processed to create liquid fuels like ethanol and diesel.

Vitrified Slag: An Inert Byproduct

All inorganic materials in the waste stream, such as metals, glass, and silica, melt under the extreme heat.

Upon cooling, these materials form a hard, glass-like substance called vitrified slag. This process permanently encapsulates heavy metals and other toxic components, rendering them non-leachable and environmentally safe. The slag can often be used as a construction aggregate.

Why Plasma Pyrolysis Over Incineration?

While both technologies reduce waste volume, their processes and environmental impacts are worlds apart.

Complete Waste Destruction

The temperatures in a plasma reactor are high enough to break down virtually any organic material, including highly stable and hazardous compounds like PCBs, medical waste, and even chemical weapons, which conventional incinerators struggle to handle completely.

Preventing Harmful Emissions

Incineration relies on combustion—burning waste with oxygen. This process is known to create highly toxic byproducts like dioxins and furans.

Because plasma pyrolysis occurs in an oxygen-starved environment, the chemical reactions that form these pollutants cannot happen.

Eliminating Toxic Ash

Incineration produces two types of ash: bottom ash and fly ash. Fly ash, in particular, is often classified as hazardous waste due to its concentration of heavy metals and requires special disposal in landfills.

Plasma pyrolysis avoids this entirely by converting inorganic materials into a stable, non-toxic vitrified slag.

Understanding the Trade-offs and Challenges

Despite its technical advantages, plasma pyrolysis is not a universal solution. Objectivity requires acknowledging its significant challenges.

High Energy Requirements

Creating and sustaining plasma is extremely energy-intensive. A plasma pyrolysis facility consumes a large amount of electricity to power the torches.

For the process to be considered a net energy producer, the energy generated from the syngas must significantly exceed the electricity consumed by the system. This net energy balance is a critical point of economic and environmental viability.

Significant Capital Investment

Plasma gasification plants are complex and require specialized, durable equipment. The initial capital cost to build such a facility is substantially higher than for a traditional landfill or even a modern incinerator.

Operational Complexity

These systems are not "set-it-and-forget-it." They require highly skilled engineers and technicians for operation and maintenance, which contributes to higher ongoing operational costs compared to simpler disposal methods.

When is Plasma Pyrolysis the Right Solution?

The decision to use plasma pyrolysis depends entirely on the specific waste stream and the project's primary goal.

- If your primary focus is hazardous waste disposal: Plasma pyrolysis is a superior choice due to its ability to completely destroy dangerous materials and safely immobilize toxic inorganic contaminants.

- If your primary focus is municipal waste-to-energy: You must carefully evaluate the economic viability, weighing the high capital costs and energy inputs against the local value of the electricity or fuels produced.

- If your primary focus is minimizing environmental impact: The technology offers a definitive advantage over incineration by preventing the formation of dioxins and toxic ash, making it a powerful tool for a circular economy.

Ultimately, plasma pyrolysis represents a powerful tool for waste conversion, turning potential environmental liabilities into valuable assets when applied to the right problem.

Summary Table:

| Aspect | Plasma Pyrolysis | Traditional Incineration |

|---|---|---|

| Process | Thermal decomposition without oxygen (pyrolysis) | Combustion with oxygen |

| Temperature | 3,000°C - 10,000°C | Typically 850°C - 1,200°C |

| Primary Output | Syngas (H₂ + CO) for energy | Heat, often for electricity |

| Solid Residue | Vitrified, non-toxic slag | Toxic fly ash and bottom ash |

| Emissions | Prevents formation of dioxins/furans | Risk of dioxin/furan formation |

| Waste Handling | Destroys hazardous compounds (e.g., PCBs, medical waste) | May not fully destroy stable hazardous compounds |

Ready to explore advanced waste conversion solutions for your laboratory or facility?

At KINTEK, we specialize in providing cutting-edge lab equipment and consumables to support innovative processes like plasma pyrolysis. Whether you're researching waste-to-energy technologies or need reliable equipment for hazardous material handling, our expertise can help you achieve precise, efficient, and environmentally sound results.

Contact us today to discuss how KINTEK's solutions can enhance your waste conversion projects and drive sustainability in your operations.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What XRF Cannot detect? Uncover the Critical Limitations of XRF Analysis

- What is plasma pyrolysis used for? Transforming Hazardous Waste into Clean Energy

- What are the three main components of biomass? Unlocking the Secrets of Cellulose, Hemicellulose, and Lignin

- What type of heat transfer is incubator? Choosing the Right Heat Transfer Method for Your Lab

- What is diffusion in sintering? Unlocking the Atomic Mechanism for Stronger Materials

- What is the sputtering process of evaporation? Understand the Key Differences in PVD

- How do you convert biomass into energy? A Guide to Thermochemical and Biochemical Methods

- What is the effect of moisture content on biomass pyrolysis? Optimize Your Biomass Conversion Efficiency