Preventive maintenance (PM) for laboratory equipment is a proactive, scheduled strategy designed to keep instruments in optimal working condition and prevent failures before they occur. It involves a routine of inspections, cleaning, calibration, part replacements, and performance testing, all documented in a detailed service history. This approach stands in direct contrast to reactive maintenance, which only addresses problems after an instrument has already broken down.

The core purpose of preventive maintenance is not merely to avoid repairs, but to safeguard the two most critical assets in any laboratory: the integrity of your data and the safety of your personnel. It is an investment in reliability and compliance.

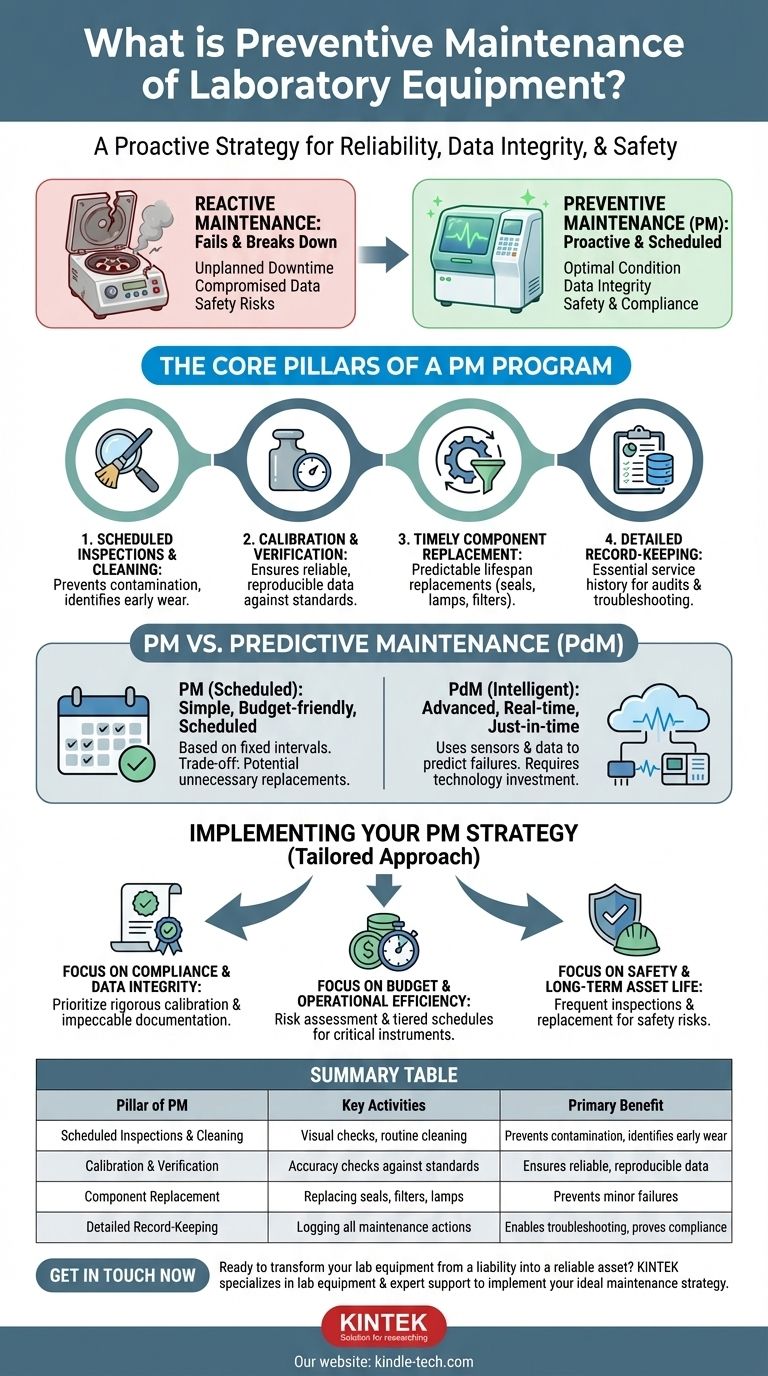

The Core Pillars of a Preventive Maintenance Program

A robust PM program is built on several key, non-negotiable activities. Each pillar works together to ensure equipment performance, longevity, and regulatory compliance.

Scheduled Inspections and Cleaning

This is the foundational layer of PM. Regular visual inspections can identify early signs of wear, corrosion, or damage, while routine cleaning prevents contamination that can affect results or harm sensitive components.

These tasks are often simple but have a massive impact on the instrument's long-term health.

Calibration and Performance Verification

Calibration ensures an instrument's measurements are accurate against a known standard. This is absolutely critical for generating reliable and reproducible data.

Without regular calibration, you cannot prove the validity of your results, putting publications, patents, and product releases at risk. This is a central requirement for labs adhering to standards like ISO/IEC 17025.

Timely Component Replacement

Many instrument parts, such as seals, filters, gaskets, and lamps, have a predictable lifespan. A PM program dictates that these are replaced based on a schedule (e.g., time or usage cycles) rather than waiting for them to fail.

This prevents a minor part failure from causing a cascade of damage to more expensive systems within the instrument.

Detailed Record-Keeping

If it wasn't documented, it didn't happen. Every PM action—from a simple cleaning to a major part replacement—must be logged.

This service history is essential for troubleshooting future issues, proving compliance during audits, and tracking the total cost of ownership for each asset.

Why Reactive Maintenance Is a Failing Strategy

Simply fixing equipment when it breaks is a shortsighted and costly approach that introduces unacceptable risks into a scientific environment.

The High Cost of Unplanned Downtime

When a critical instrument like a mass spectrometer or an HPLC fails unexpectedly, research grinds to a halt. This unplanned downtime leads to missed deadlines, delayed projects, and lost revenue.

Emergency repairs and rush shipping of parts are also significantly more expensive than planned maintenance activities.

Compromised Data Integrity

An instrument can drift out of specification long before it fails completely. During this period, it produces inaccurate and unreliable data.

This is the most insidious risk, as it can go unnoticed and invalidate weeks or months of work, forcing costly and time-consuming re-testing.

Increased Safety Risks

Equipment failure can pose a direct threat to personnel. A malfunctioning centrifuge, a leaking biosafety cabinet, or an improperly sealed autoclave are all serious safety hazards.

Preventive maintenance is a critical component of a laboratory's overall safety management system.

Understanding the Trade-offs: PM vs. Predictive Maintenance

While PM is a massive improvement over a reactive approach, it's important to understand where it fits in the broader maintenance landscape.

The Simplicity of Preventive Maintenance (PM)

PM is based on predetermined schedules. It is relatively straightforward to implement, budget for, and manage.

The primary trade-off is that it can sometimes lead to unnecessary work, such as replacing a component that is still in good condition simply because the schedule dictates it.

The Intelligence of Predictive Maintenance (PdM)

PdM is a more advanced strategy that uses sensors and data analysis to monitor the actual condition of equipment in real-time. It aims to predict exactly when a failure will occur so maintenance can be performed just in time.

While highly efficient, PdM requires a greater upfront investment in technology (sensors, software) and expertise to interpret the data.

Finding the Right Mix

For most laboratories, a hybrid approach is best. Use time-tested PM schedules for most standard equipment, and consider investing in PdM solutions for only the most critical, high-value instruments where unexpected downtime would be catastrophic.

Implementing Your Laboratory's PM Strategy

Building a successful PM program requires a structured approach tailored to your specific operational goals.

- If your primary focus is compliance and data integrity: Prioritize rigorous calibration schedules and create an impeccable, audit-proof documentation trail for every instrument.

- If your primary focus is budget and operational efficiency: Begin with a risk assessment to identify your most critical instruments and implement a tiered PM schedule that directs resources where they matter most.

- If your primary focus is safety and long-term asset life: Concentrate on frequent inspections and the scheduled replacement of wear-and-tear components on equipment that poses a potential safety risk, like autoclaves and fume hoods.

Ultimately, a well-executed preventive maintenance program transforms your equipment from a potential liability into a consistently reliable asset that empowers your work.

Summary Table:

| Pillar of PM | Key Activities | Primary Benefit |

|---|---|---|

| Scheduled Inspections & Cleaning | Visual checks, routine cleaning | Prevents contamination, identifies early wear |

| Calibration & Verification | Accuracy checks against standards | Ensures reliable, reproducible data |

| Component Replacement | Replacing seals, filters, lamps on a schedule | Prevents minor failures from causing major damage |

| Detailed Record-Keeping | Logging all maintenance actions | Enables troubleshooting and proves compliance |

Ready to transform your lab equipment from a liability into a reliable asset?

A proactive preventive maintenance plan is an investment in the integrity of your data, the safety of your team, and the efficiency of your operations. KINTEK specializes in providing the lab equipment and consumables your laboratory needs, backed by expert support to help you implement a maintenance strategy that fits your goals—whether your focus is on compliance, budget efficiency, or safety.

Contact us today to discuss how we can help you build a robust preventive maintenance program for your critical instruments.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Freeze Dryer for Lab Use

- Anti-Cracking Press Mold for Lab Use

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing