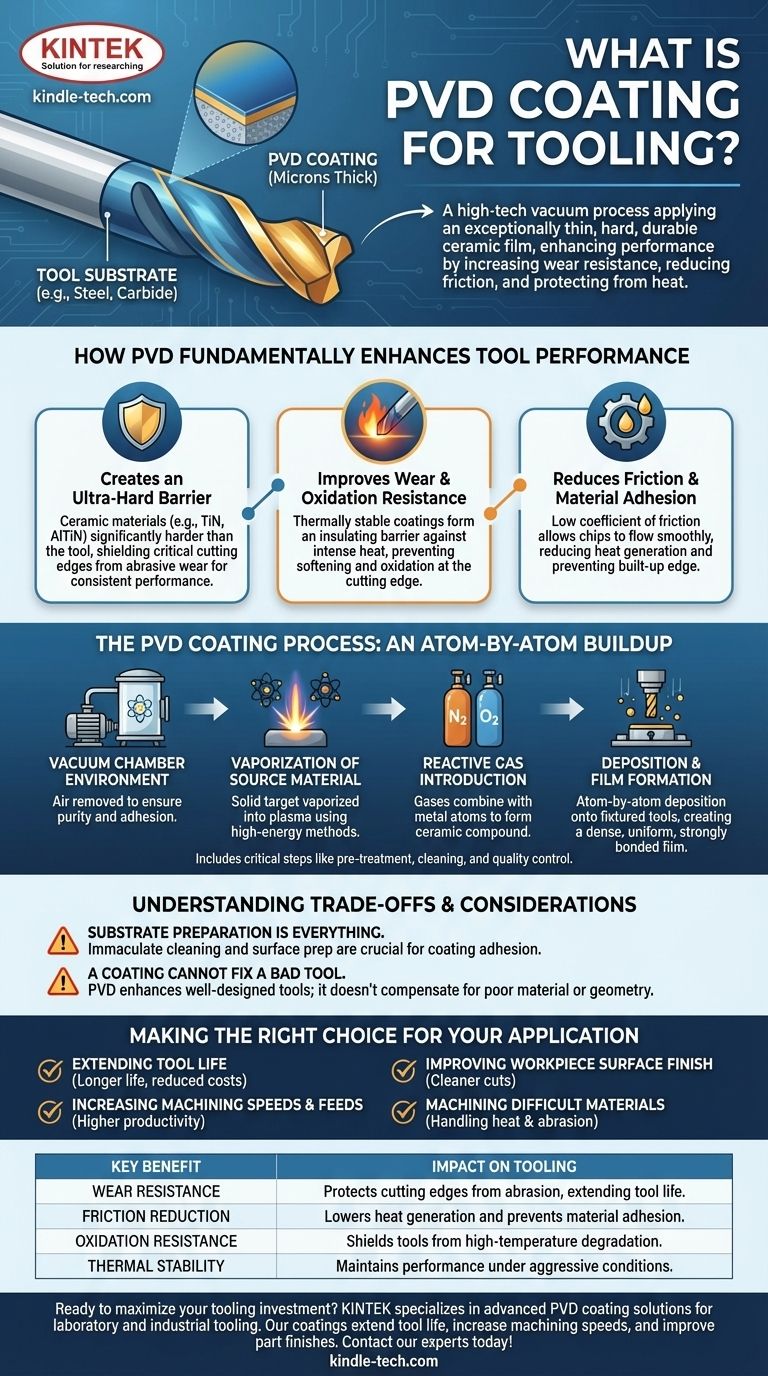

In essence, Physical Vapor Deposition (PVD) coating for tooling is a high-tech vacuum process that applies an exceptionally thin but extremely hard and durable ceramic film onto a tool's surface. This isn't paint or plating; it's a bonded layer, often just a few microns thick, that fundamentally enhances the tool's performance by increasing its wear resistance, reducing friction, and protecting it from high-temperature oxidation during demanding operations.

The core purpose of PVD coating is not to repair a tool, but to elevate a well-made tool to its maximum potential. It extends operational life and enables higher performance parameters by creating a superior surface that is harder, more lubricious, and more durable than the base tool steel or carbide alone.

How PVD Fundamentally Enhances Tool Performance

PVD coatings directly address the primary failure points of cutting tools: wear, heat, and friction. By applying a microscopic layer of advanced material, the coating creates a new, high-performance working surface.

Creating an Ultra-Hard Barrier

The ceramic materials used in PVD coatings, such as Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN), are significantly harder than the tool's base material. This hard layer acts as a shield, protecting the critical cutting edges from abrasive wear.

This allows the tool to maintain its sharp geometry for a much longer period, resulting in consistent performance and improved part quality.

Improving Wear and Oxidation Resistance

During cutting, intense heat is generated at the tool's tip. This heat can cause the tool material to soften and oxidize, rapidly dulling the edge.

PVD coatings are engineered to be thermally stable, forming a barrier that insulates the tool from the intense heat of the cutting zone and prevents oxidation.

Reducing Friction and Material Adhesion

Many PVD coatings have a low coefficient of friction. This lubricity allows chips to flow more smoothly across the tool face, reducing heat generation and power consumption.

It also prevents workpiece material from welding onto the tool, a phenomenon known as "built-up edge," which degrades the cutting action and harms the surface finish.

The PVD Coating Process: An Atom-by-Atom Buildup

The PVD process is a sophisticated technique that occurs within a high-vacuum chamber. This controlled environment is essential for ensuring the purity and adhesion of the coating.

The Vacuum Chamber Environment

All PVD processes begin by creating a vacuum to remove air and any other contaminants. This ensures that the coating material is the only substance that deposits onto the tools, guaranteeing a pure and highly adherent film.

Vaporization of the Source Material

A solid, high-purity source material (the "target") is vaporized into a plasma of individual atoms or molecules. This is typically achieved using high-energy methods like a cathodic arc or ion bombardment.

Reactive gases, such as nitrogen or oxygen, can be precisely introduced into the chamber to combine with the vaporized metal atoms, creating the desired ceramic compound for the coating.

Deposition and Film Formation

The vaporized material travels through the vacuum chamber and condenses onto the surfaces of the tools, which are fixtured inside. This deposition happens atom by atom, creating a film that is extremely dense, uniform, and strongly bonded to the substrate.

The Industrial Workflow

The coating itself is just one part of a multi-stage industrial process that includes critical steps like pre-treatment, ultrasonic cleaning, fixturing, visual inspection, and post-process quality control to ensure proper thickness and adhesion.

Understanding the Trade-offs and Considerations

While highly effective, PVD coating is not a universal solution. Its success depends on understanding its requirements and limitations.

Substrate Preparation is Everything

The coating is only as good as its bond to the tool. The tool's surface must be immaculately clean and properly prepared. Any contamination will compromise adhesion and lead to premature coating failure.

A Coating Cannot Fix a Bad Tool

PVD enhances the properties of a well-designed tool; it cannot compensate for poor tool material, incorrect geometry, or a dull cutting edge. The base tool must be of high quality for the coating to provide a benefit.

Edge Sharpness and Buildup

While the coating is very thin, it does add material. For tools with extremely sharp or delicate cutting edges, the coating process must be carefully controlled to avoid rounding the edge and negatively impacting its cutting ability.

Making the Right Choice for Your Application

Applying PVD coating is a strategic decision to maximize tooling investment and operational efficiency. Your specific goal will determine its value.

- If your primary focus is extending tool life: PVD provides a hard, wear-resistant barrier that allows tools to last significantly longer, reducing replacement costs and machine downtime.

- If your primary focus is increasing machining speeds and feeds: The coating's thermal stability and low friction enable you to run tools more aggressively, increasing throughput and productivity.

- If your primary focus is improving workpiece surface finish: The anti-stick properties prevent material buildup on the tool, resulting in cleaner cuts and superior part finishes.

- If your primary focus is machining difficult materials: Specialized PVD coatings are designed to handle the extreme heat and abrasion generated when cutting hardened steels, superalloys, or composites.

Ultimately, viewing PVD coating as an integral part of your tooling strategy is the key to unlocking new levels of performance and efficiency in your manufacturing operations.

Summary Table:

| Key Benefit | Impact on Tooling |

|---|---|

| Wear Resistance | Protects cutting edges from abrasion, extending tool life. |

| Friction Reduction | Lowers heat generation and prevents material adhesion. |

| Oxidation Resistance | Shields tools from high-temperature degradation. |

| Thermal Stability | Maintains performance under aggressive machining conditions. |

Ready to maximize your tooling investment? KINTEK specializes in advanced PVD coating solutions for laboratory and industrial tooling. Our coatings are designed to extend tool life, increase machining speeds, and improve part finishes—delivering measurable efficiency gains. Contact our experts today to discuss how we can enhance your tooling performance!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition