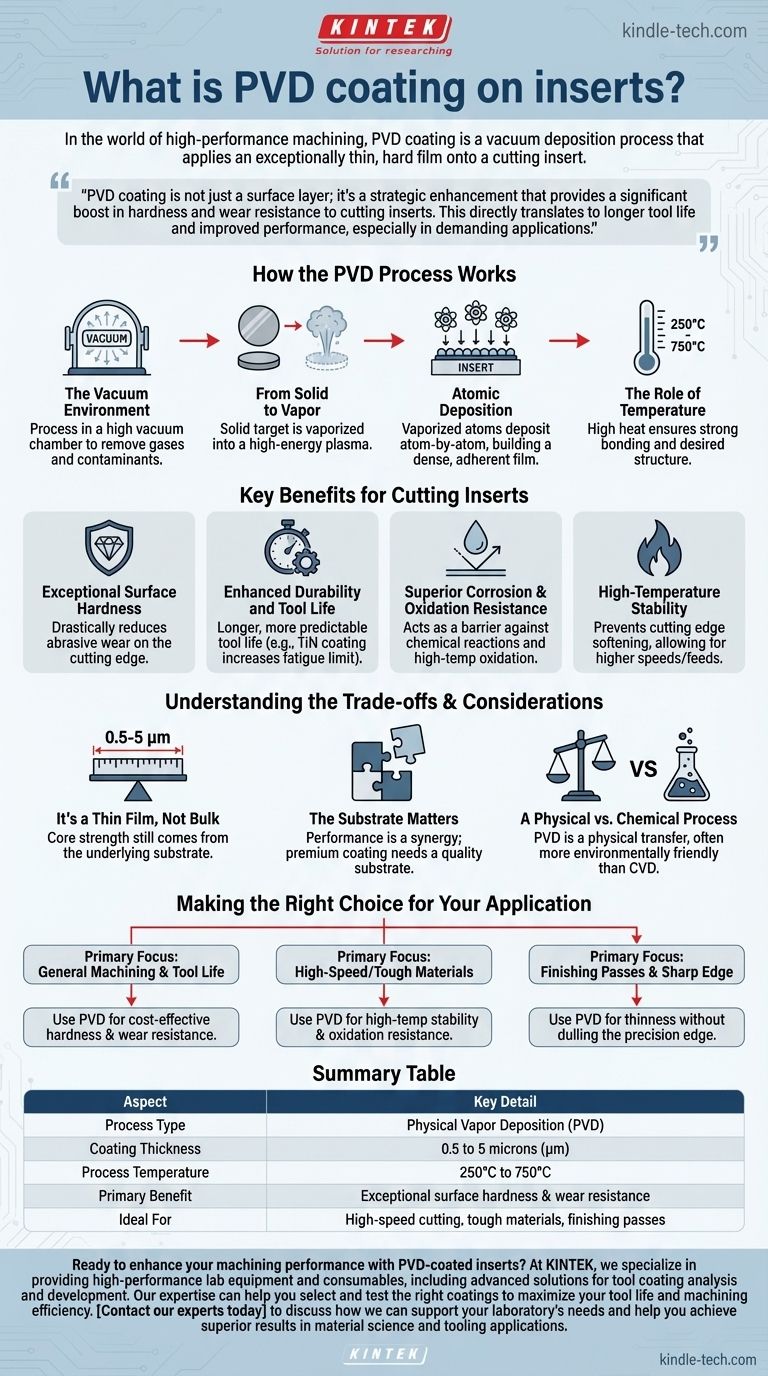

In the world of high-performance machining, PVD coating is a vacuum deposition process that applies an exceptionally thin, hard film onto a cutting insert. This technique works by vaporizing a solid material, which then condenses atom by atom onto the tool's surface. The result is a molecular-level enhancement of the insert's physical properties without altering its core geometry.

PVD coating is not just a surface layer; it's a strategic enhancement that provides a significant boost in hardness and wear resistance to cutting inserts. This directly translates to longer tool life and improved performance, especially in demanding applications.

How the PVD Process Works

Physical Vapor Deposition (PVD) is a sophisticated process that transforms a solid material into a durable, high-performance coating. The entire operation takes place within a specialized, controlled environment.

The Vacuum Environment

The process must be carried out in a high vacuum chamber. This removes any atmospheric gases or contaminants that could interfere with the coating's purity and adhesion.

From Solid to Vapor

The coating material, known as the "target," begins as a solid wafer. Inside the vacuum chamber, this target is vaporized into a plasma, which is a high-energy state of matter.

Atomic Deposition

The vaporized atoms or molecules travel through the vacuum and are deposited onto the cutting inserts, which are called the "substrate." This builds the coating one atom at a time, creating an extremely dense and well-adhered thin film.

The Role of Temperature

This physical process is performed at high temperatures, typically ranging from 250°C to 750°C. This heat is critical for ensuring the coating bonds strongly to the insert's surface and forms the desired structure.

Key Benefits for Cutting Inserts

Applying a PVD coating fundamentally changes the performance characteristics of an insert. The benefits are directly tied to overcoming the common challenges faced in machining.

Exceptional Surface Hardness

PVD coatings are extremely hard, which is the primary reason for their use. This added hardness drastically reduces abrasive wear on the cutting edge as it engages with the workpiece.

Enhanced Durability and Tool Life

The increased hardness and wear resistance lead directly to a longer and more predictable tool life. For example, a Titanium Nitride (TiN) PVD coating can increase the fatigue limit and endurance of the underlying material.

Superior Corrosion and Oxidation Resistance

The dense, non-porous nature of the PVD film acts as a barrier, protecting the insert from chemical reactions. This makes it highly resistant to corrosion from coolants and oxidation at high cutting temperatures.

High-Temperature Stability

The resulting coated layer is very stable at the high temperatures generated during aggressive cutting operations. This prevents the cutting edge from softening, allowing for higher speeds and feeds.

Understanding the Trade-offs and Considerations

While powerful, PVD coatings are not a universal solution. Their effectiveness is dependent on understanding their nature and how they interact with the tool itself.

It's a Thin Film, Not a Bulk Material

PVD coatings are incredibly thin, typically ranging from 0.5 to 5 microns (μm). This means they provide surface properties, but the insert's core strength and toughness still come from the underlying substrate material.

The Substrate Matters

The final performance is a synergy between the coating and the insert. The benefits of a coating are directly influenced by the material it is applied to. A premium coating cannot compensate for a low-quality substrate.

A Physical vs. Chemical Process

PVD is a physical process, where the source material is physically transferred to the part. This contrasts with Chemical Vapor Deposition (CVD), which uses chemical reactions to form the film. PVD is often considered more environmentally friendly than traditional plating or CVD processes.

Making the Right Choice for Your Application

Knowing when to specify a PVD-coated insert over an uncoated or alternatively coated one is key to optimizing your machining strategy.

- If your primary focus is extending tool life in general machining: PVD coatings provide a cost-effective and significant increase in hardness and wear resistance.

- If your primary focus is high-speed cutting or working with tough materials: The high-temperature stability and oxidation resistance of PVD are critical advantages that protect the cutting edge.

- If your primary focus is maintaining a sharp cutting edge for finishing passes: The thin, smooth nature of PVD coatings is ideal, as it adds durability without significantly dulling the precision edge required for fine surface finishes.

Ultimately, understanding PVD coating allows you to select a cutting insert based on a precise enhancement of its core properties, leading to more predictable and efficient machining.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Coating Thickness | 0.5 to 5 microns (µm) |

| Process Temperature | 250°C to 750°C |

| Primary Benefit | Exceptional surface hardness & wear resistance |

| Ideal For | High-speed cutting, tough materials, finishing passes |

Ready to enhance your machining performance with PVD-coated inserts?

At KINTEK, we specialize in providing high-performance lab equipment and consumables, including advanced solutions for tool coating analysis and development. Our expertise can help you select and test the right coatings to maximize your tool life and machining efficiency.

Contact our experts today to discuss how we can support your laboratory's needs and help you achieve superior results in material science and tooling applications.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom PTFE Teflon Parts Manufacturer for Magnetic Stirring Bar

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process