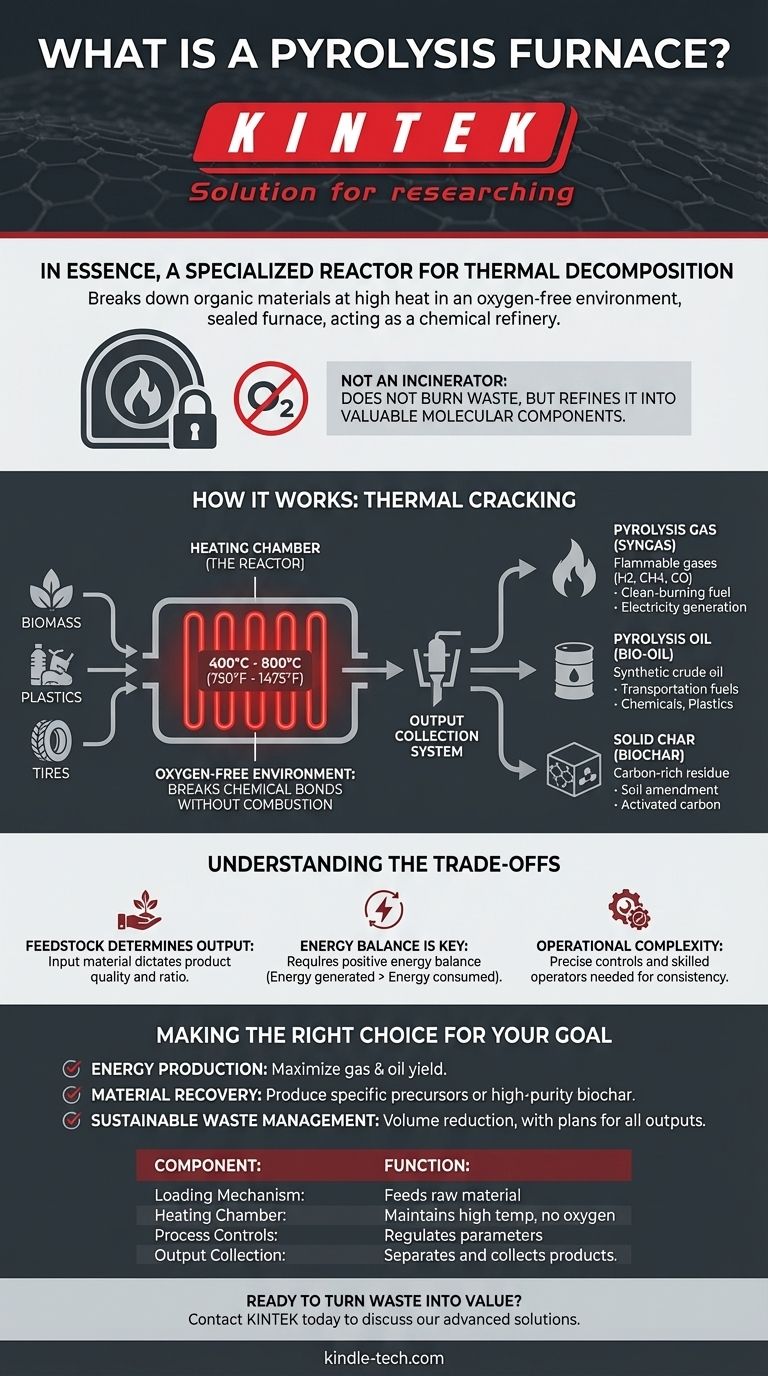

In essence, a pyrolysis furnace is a specialized reactor designed for thermal decomposition. It uses extremely high temperatures to break down organic materials—such as biomass, plastics, or tires—in an environment completely devoid of oxygen, preventing combustion and instead transforming the material into a mix of valuable gases, liquids, and a solid carbon residue.

A pyrolysis furnace should not be confused with an incinerator. Its primary function is not to destroy waste by burning it, but to act as a chemical refinery, deconstructing complex organic matter into simpler, more valuable molecular components.

How a Pyrolysis Furnace Works

A pyrolysis furnace operates on the principle of thermal cracking. By applying intense heat without oxygen, it systematically breaks the long-chain chemical bonds in organic materials, rather than causing them to combust (burn).

The Critical Role of an Oxygen-Free Environment

The absence of oxygen is the defining characteristic of pyrolysis. In the presence of oxygen, high heat leads to combustion, which releases energy and produces ash, carbon dioxide, and other combustion byproducts.

By removing oxygen, the furnace forces the material to decompose into its fundamental constituents, which then reform into new, smaller molecules.

Key Functional Components

While designs vary, all pyrolysis furnaces share a common set of functional components that manage the transformation process.

- Loading Mechanism: A system, often automated, for feeding the raw organic material (feedstock) into the main chamber.

- Heating Chamber (The Reactor): This is the sealed, oxygen-free heart of the furnace. Powerful heating elements raise the internal temperature to a precise, controlled level, often between 400°C and 800°C (750°F to 1475°F).

- Process Controls: A sophisticated system that monitors and regulates temperature, pressure, and processing time. These controls are critical, as slight adjustments can dramatically alter the ratio and quality of the final products.

- Output Collection System: As the material decomposes, the resulting gases and vaporized liquids are channeled out of the reactor. They are then cooled, causing the liquids (pyrolysis oil) to condense and separate from the non-condensable gases (syngas). The solid char remains in the reactor for collection.

The Outputs: From Waste to Valuable Products

The true purpose of pyrolysis is to create new resources. The process yields three distinct product streams, each with its own applications.

Pyrolysis Gas (Syngas)

This is a mixture of flammable gases, including hydrogen, methane, and carbon monoxide. It can be refined and used as a clean-burning fuel to power the pyrolysis process itself or generate electricity.

Pyrolysis Oil (Bio-oil)

This dark, viscous liquid is a type of synthetic crude oil. It can be upgraded into transportation fuels like diesel or used as a feedstock for producing specialty chemicals and plastics.

Solid Char (Biochar)

The solid, carbon-rich residue left behind is called char or biochar. Depending on the feedstock, this material can be used as a soil amendment to improve agricultural fertility or processed further to create high-grade activated carbon for filtration purposes.

Understanding the Trade-offs

Pyrolysis is a powerful technology, but its application requires a clear understanding of its operational realities and limitations.

Feedstock Determines Output

The system is highly sensitive to the input material. The composition of the feedstock—whether it's wood chips, waste plastic, or old tires—directly dictates the proportion and chemical makeup of the resulting gas, oil, and char.

Energy Balance is Key

A pyrolysis furnace consumes a significant amount of energy to reach and maintain its high operating temperatures. A successful operation depends on a positive energy balance, where the energy value of the products generated is greater than the energy required to run the system.

Operational Complexity

These are not "set it and forget it" machines. Achieving a consistent and high-quality output requires precise control over the process parameters and skilled operators who can adjust to variations in feedstock and conditions.

Making the Right Choice for Your Goal

Evaluating pyrolysis technology requires matching the process to your specific objective.

- If your primary focus is energy production: You will prioritize systems and feedstocks that maximize the yield of high-calorific pyrolysis gas and oil.

- If your primary focus is material recovery: Your goal will be to fine-tune the furnace controls to produce specific chemical precursors or a high-purity solid biochar.

- If your primary focus is sustainable waste management: Pyrolysis offers immense volume reduction, but success depends on having a viable plan for utilizing all three distinct output streams.

Understanding the furnace as a tool for controlled chemical transformation empowers you to see its potential beyond simple waste disposal.

Summary Table:

| Component | Function |

|---|---|

| Loading Mechanism | Feeds raw organic material (feedstock) into the sealed reactor. |

| Heating Chamber | Maintains high temperatures (400°C–800°C) in an oxygen-free environment. |

| Process Controls | Regulates temperature, pressure, and processing time for optimal output. |

| Output Collection | Separates and collects pyrolysis gas, oil, and solid char. |

Ready to turn your waste streams into valuable products? KINTEK specializes in advanced pyrolysis furnaces and lab equipment designed for efficient material recovery and sustainable waste management. Whether your goal is energy production, chemical feedstock generation, or volume reduction, our solutions are tailored to maximize your output. Contact our experts today to discuss how our technology can support your specific laboratory or industrial needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products