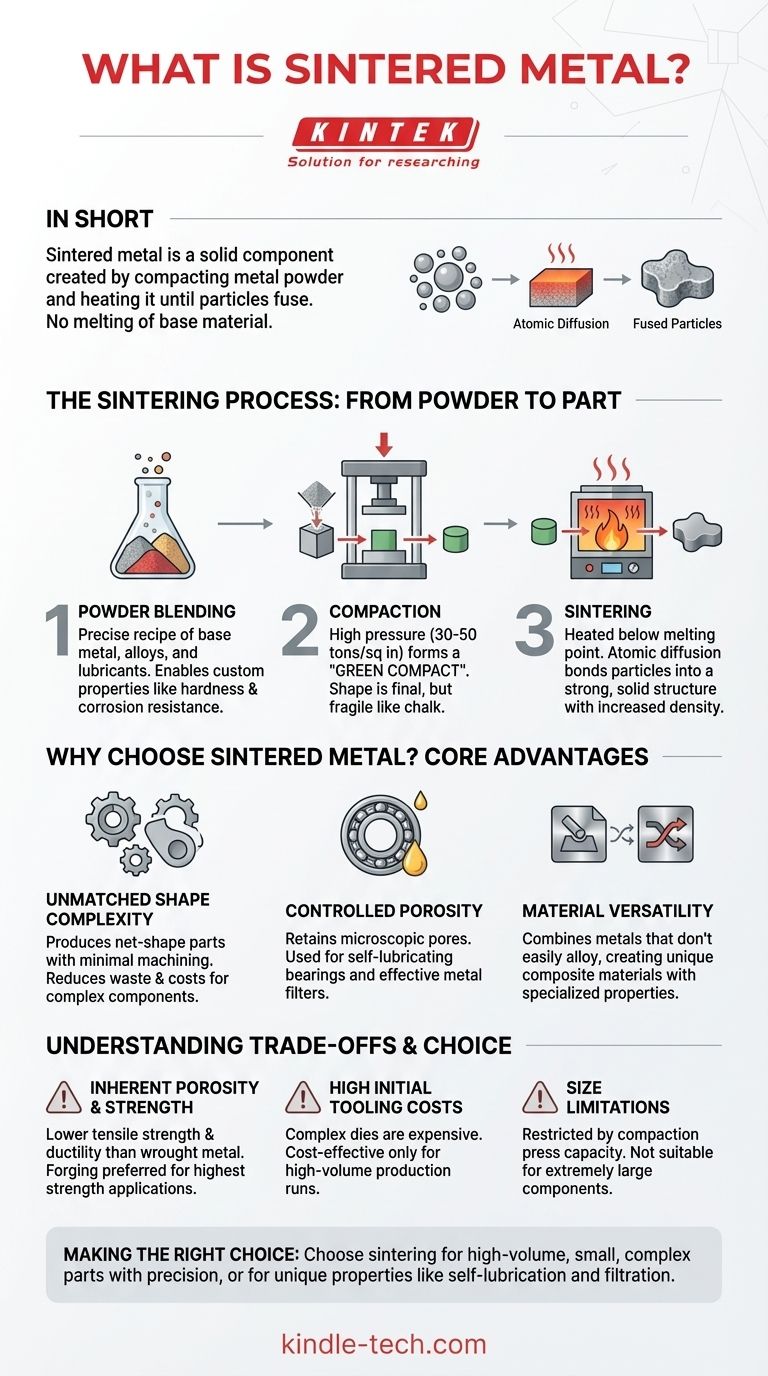

In short, sintered metal is a solid component created by compacting metal powder and heating it until the particles fuse together. This process, a key part of powder metallurgy, forges a strong, precise, and often complex part without ever melting the base material.

Sintering is more than just a manufacturing method; it is a specialized engineering tool that allows for the creation of components with unique properties—such as controlled porosity or custom alloy blends—that are difficult or impossible to achieve with traditional casting or forging.

The Sintering Process: From Powder to Part

Understanding sintered metal requires understanding the three core stages of its creation. The final part's properties are defined by the precision applied at each step.

Step 1: Powder Blending

Before any shaping occurs, a precise recipe of metal powders is created. The base metal (like iron or copper) is mixed with other alloying elements (like nickel or molybdenum) and often a lubricant to improve compaction.

This blending stage is critical because it allows for the creation of custom materials with tailored properties for hardness, corrosion resistance, or magnetism.

Step 2: Compaction

The blended powder is fed into a high-precision die and compacted under immense pressure (typically 30-50 tons per square inch).

This pressure forces the powder into the desired shape, creating what is known as a "green compact." This part has the shape and dimensions of the final product but is fragile, with a consistency similar to a piece of chalk.

Step 3: Sintering

The green compact is then placed in a controlled-atmosphere furnace and heated to a temperature below its melting point. At this high temperature, a process of atomic diffusion occurs. The metal particles fuse at their contact points, bonding them into a solid, strong metallic structure.

The final part is now a rigid, metallic component with significantly increased density, hardness, and strength.

Why Choose Sintered Metal? The Core Advantages

Sintering is not a replacement for all metal manufacturing, but it offers distinct advantages for specific engineering challenges.

Unmatched Shape Complexity

Sintering excels at producing intricate, net-shape parts that require little to no secondary machining. This dramatically reduces material waste and manufacturing costs for complex components like gears, cams, and structural parts.

Controlled Porosity

Because the process starts with powder, the final part retains a degree of microscopic porosity. This isn't a flaw; it's a feature that can be precisely controlled.

This controlled porosity is used to create self-lubricating bearings (which hold oil in their pores) and highly effective metal filters for fluids and gases.

Material Versatility

Sintering makes it possible to combine metals that would not typically alloy in a molten state. This allows for the creation of unique composite materials with specialized electrical or wear-resistant properties.

Understanding the Trade-offs

No process is perfect. Objectivity requires acknowledging the limitations of sintering.

Inherent Porosity and Strength

While porosity can be an advantage, it also means that standard sintered parts typically have lower tensile strength and ductility than parts made from wrought or forged metal. For applications demanding the absolute highest strength, forging is often superior.

High Initial Tooling Costs

The dies required for compaction are complex and expensive to produce. This makes sintering highly cost-effective for high-volume production runs but uneconomical for prototypes or low-volume orders.

Size Limitations

The size of a part that can be sintered is limited by the capacity of the compaction press. Extremely large components are generally not suitable for this process.

Making the Right Choice for Your Application

Use these guidelines to determine if sintering aligns with your project's goals.

- If your primary focus is mass-producing small, complex parts with high precision: Sintering is an excellent choice due to its net-shape capabilities and low material waste.

- If your primary focus is creating a component with unique properties like self-lubrication or filtration: Sintering is one of the few processes that can achieve controlled, interconnected porosity.

- If your primary focus is achieving the maximum possible strength for a high-stress component: A forged or machined part from solid bar stock is likely the better and safer option.

Ultimately, choosing sintered metal is a strategic decision to solve specific engineering problems with elegance and efficiency.

Summary Table:

| Property | Sintered Metal Characteristic |

|---|---|

| Process | Powder compaction & heating below melting point |

| Key Advantage | Creates complex, net-shape parts with minimal waste |

| Unique Feature | Controlled porosity for self-lubrication or filtration |

| Strength vs. Wrought Metal | Generally lower tensile strength and ductility |

| Best For | High-volume production of intricate components |

Need a reliable partner for your lab's sintering or material testing needs? KINTEK specializes in high-quality lab equipment and consumables, providing the precise tools and expertise to support your powder metallurgy projects. From furnaces to material analysis, we help you achieve superior results. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What temperature does tungsten carbide sinter at? Master the 1350°C-1500°C Liquid-Phase Sintering Process

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance