In additive manufacturing, sintering is a thermal process that fuses powdered material together to form a solid object, layer by layer. It achieves this by applying heat at a temperature below the material's melting point, causing the individual particles to bond at an atomic level without ever turning into a liquid.

The critical distinction to understand is that sintering is not melting. It is a solid-state process that fuses particles together, much like tightly packing snowballs until they form a single block of ice, which fundamentally differs from processes that fully melt powder into a liquid pool.

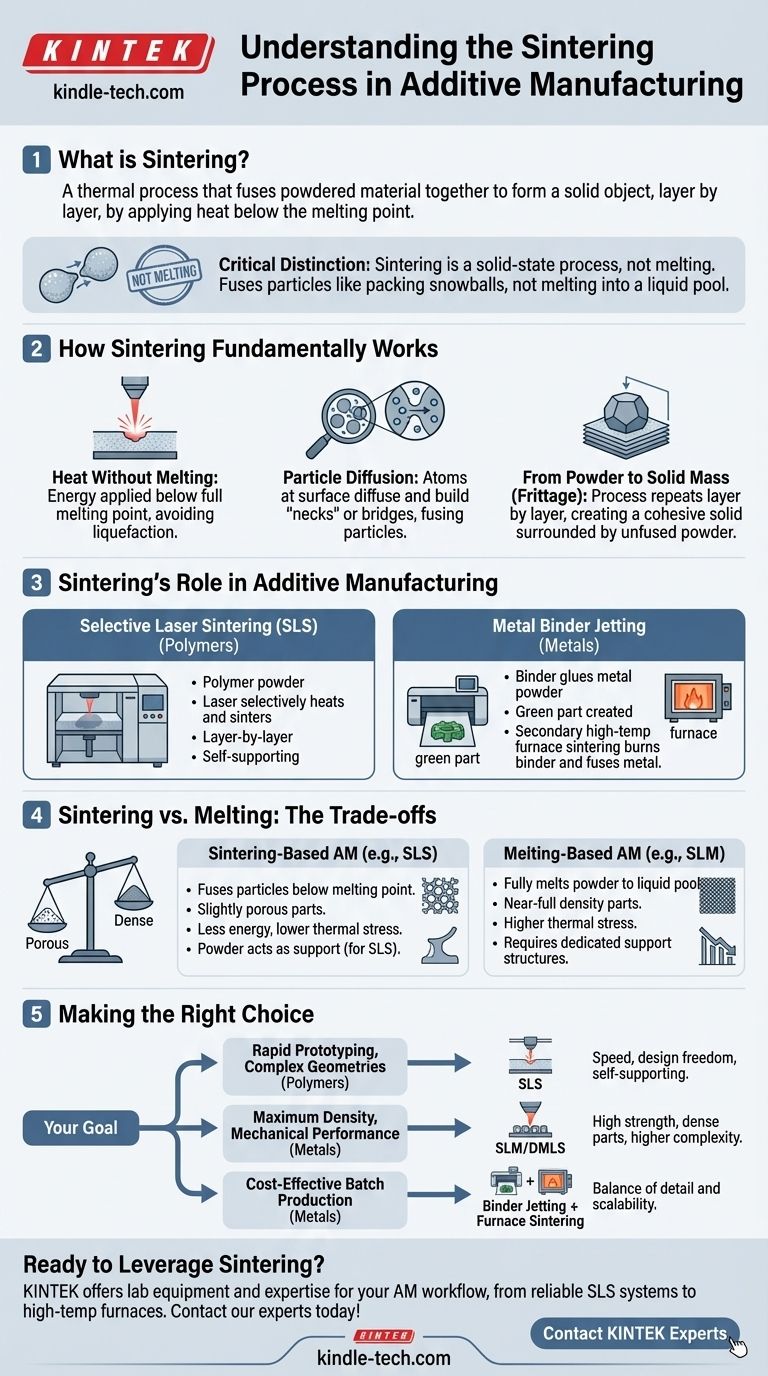

How Sintering Fundamentally Works

Sintering is a long-established manufacturing principle, traditionally used in ceramics and powder metallurgy, that has been adapted for modern 3D printing. Its effectiveness relies on a simple but powerful physical transformation.

The Core Principle: Heat Without Melting

The defining characteristic of sintering is the careful application of energy—typically from a laser or electron beam—to heat a material to a point where its atoms become highly active.

This temperature is kept just below the material's full melting point. This prevents the material from liquefying, which avoids issues related to high thermal stress and the need for extensive support structures found in melting-based processes.

The Atomic Level: Particle Diffusion

At this elevated temperature, the atoms at the surface of each powder particle begin to vibrate and move rapidly.

This activity allows atoms to diffuse across the boundaries of adjacent particles. This atomic migration effectively builds "necks" or bridges between the particles, fusing them together into a single, cohesive mass.

The Result: From Powder to Solid Mass

As the energy source scans the powder bed according to the digital design, it leaves a trail of fused, solid material. This process, also known as frittage, repeats layer by layer until the final three-dimensional object is complete, surrounded by unfused powder that can often be recycled.

Sintering's Role in Additive Manufacturing

While the principle is universal, its application is most prominent in powder-bed fusion technologies. These processes leverage sintering to create complex parts directly from a digital file.

Selective Laser Sintering (SLS) Explained

Selective Laser Sintering (SLS) is the most common sintering-based AM technology. In an SLS machine, a thin layer of polymer powder (like nylon) is spread across a build platform.

A high-powered CO2 laser then selectively scans the cross-section of the part for that layer. The laser's energy heats the powder just enough to sinter the particles together. The platform then lowers, a new layer of powder is applied, and the process repeats.

Sintering in Metal AM

Sintering is also critical for some forms of metal 3D printing. In processes like Metal Binder Jetting, a liquid binding agent is first used to "glue" metal powder particles together, creating a fragile "green part."

This green part is then removed from the printer and placed into a high-temperature furnace. In the furnace, the part undergoes a secondary sintering process that burns away the binder and fuses the metal particles into a dense, solid component.

Understanding the Trade-offs: Sintering vs. Melting

Choosing between an AM process that sinters and one that melts (like Selective Laser Melting, or SLM) involves clear trade-offs tied to your final goal.

The Impact on Part Properties

Because sintering does not fully liquefy the material, the resulting parts are inherently somewhat porous. While this porosity is often minimal and acceptable for many applications, fully melting the powder generally produces denser, stronger parts.

Advantages of the Sintering Method

Sintering requires less energy input and induces lower thermal stress on the part during the build process. A major advantage in SLS is that the surrounding unsintered powder acts as a natural support structure, allowing for the creation of complex geometries and interlocking parts without dedicated supports.

Post-Processing Considerations

Parts made via melting often require significant stress-relief heat treatments. Sintering-based processes may have different requirements. For example, parts from Metal Binder Jetting require the furnace sintering step to achieve their final properties, making it an integral part of the workflow.

Making the Right Choice for Your Goal

Selecting a powder-bed technology depends entirely on your project's specific material, performance, and geometric requirements.

- If your primary focus is rapid prototyping or complex geometries with polymers: SLS is an excellent choice due to its speed, design freedom, and self-supporting nature.

- If your primary focus is maximum density and mechanical performance in metal parts: A melting-based process like SLM or DMLS might be more suitable, despite its higher complexity and cost.

- If your primary focus is cost-effective batch production of metal parts: Metal Binder Jetting followed by a furnace sintering step can offer a compelling balance of detail and scalability.

Ultimately, understanding sintering empowers you to look past the marketing terms and evaluate powder-based AM technologies based on their core physical principles and how they align with your engineering goals.

Summary Table:

| Aspect | Sintering-Based AM (e.g., SLS) | Melting-Based AM (e.g., SLM) |

|---|---|---|

| Process Principle | Fuses particles below melting point | Fully melts powder into a liquid pool |

| Typical Porosity | Slightly porous | Near-full density |

| Support Structures | Un-sintered powder acts as support | Requires dedicated support structures |

| Ideal For | Complex geometries, rapid prototyping | High-strength, dense metal parts |

Ready to leverage sintering for your next project? Whether you need a reliable SLS system for prototyping or a high-temperature furnace for metal binder jetting, KINTEK has the lab equipment and expertise to support your additive manufacturing workflow. Contact our experts today to find the perfect solution for your laboratory's needs!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- How does a magnetic stirring system contribute to the chemical synthesis of chlorine dioxide? Ensure Safety and Purity

- Why is it necessary to control the temperature during composite specimen preparation? Ensure Flawless Resin Infusion

- What are the end products of pyrolysis? Turn Waste into Biochar, Oil, and Syngas

- What are the hazards of heat treatment process? Avoid Oxidation, Embrittlement, and Costly Defects

- What is the difference between high quartz and low quartz? Unlock the Key to Crystal Behavior and Applications

- What is the cause of arc formation? The Physics of Electrical Discharge Explained

- What equipment is needed for pyrolysis? The 4 Core Components for a Successful Plant

- What are the factors that affect heat transfer? Master the Key Variables for Optimal Thermal Performance