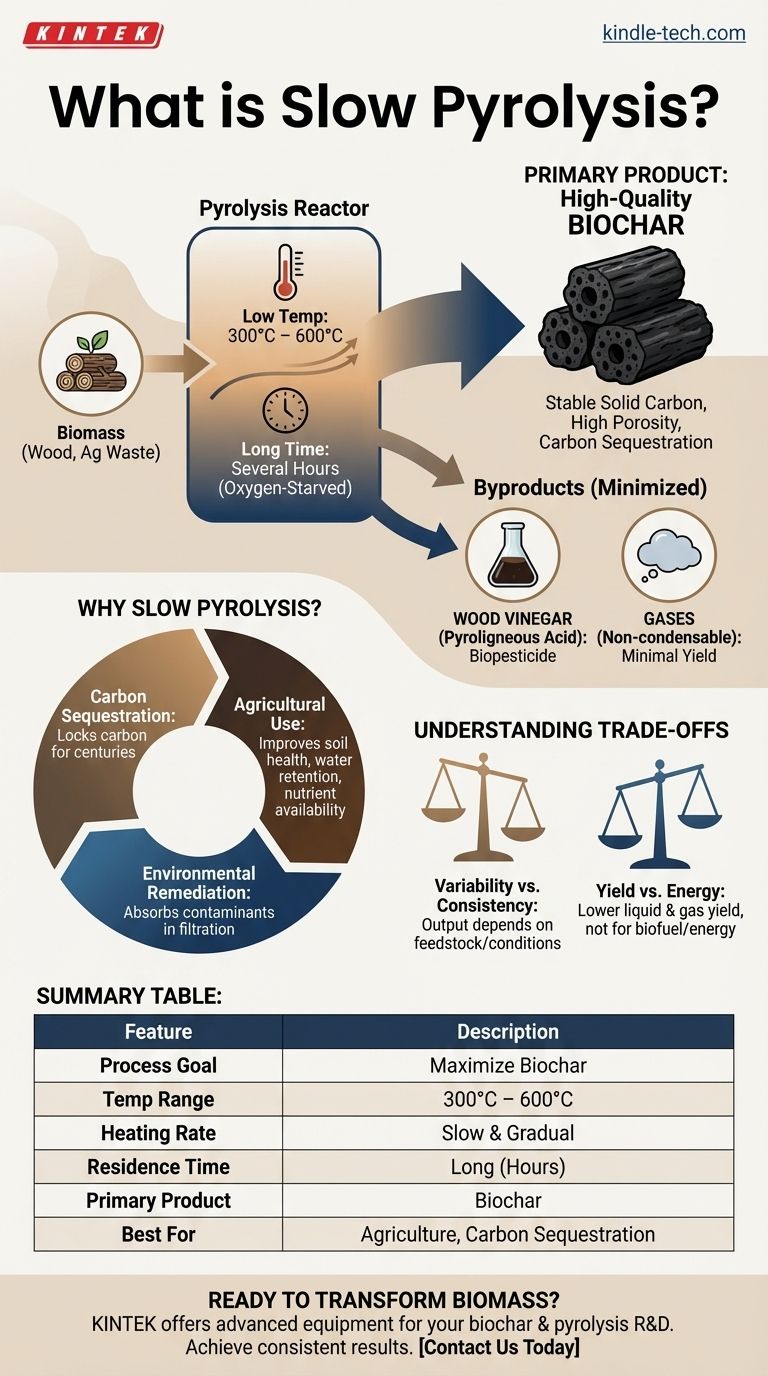

In essence, slow pyrolysis is a thermochemical process that heats organic materials, like wood or agricultural waste, at low temperatures over a long period in an oxygen-starved environment. Unlike faster methods designed to produce liquids or gases, the primary goal of slow pyrolysis is to maximize the quantity and quality of the solid carbon-rich product, known as biochar.

Slow pyrolysis is best understood not as a way to create energy, but as a method to transform organic waste into a stable, solid carbon product (biochar) for agricultural or industrial use. The process is defined by its slow heating rate and long duration, which favors solid output over liquids and gases.

Deconstructing the Process

To understand slow pyrolysis, it's helpful to break down its core components: temperature, time, and the resulting products. The interplay between these factors defines the process and its unique outcomes.

The Core Principle: Low and Slow

Slow pyrolysis uses relatively low temperatures, typically between 300°C and 600°C. The feedstock is heated gradually and kept at this temperature for an extended period, often for several hours.

This "low and slow" approach allows for the complete carbonization of the biomass. It systematically breaks down complex organic polymers, driving off volatile compounds and leaving behind a stable, carbon-dense solid structure.

Key Inputs and Outputs

The process begins with a carbon-based feedstock, most commonly wood or other forms of biomass. The outputs are primarily solid, with some liquid and gas byproducts.

The two major products are:

- Biochar (or Biocoal): A black, highly porous, and stable solid that is rich in carbon. This is the main target product, and its yield is maximized.

- Wood Vinegar (Pyroligneous Acid): A dark, aqueous liquid byproduct with potential uses as a biopesticide or plant growth stimulant.

A smaller amount of non-condensable gases is also produced, but their yield is intentionally minimized, distinguishing this process from methods focused on energy generation.

Why Choose Slow Pyrolysis? The Biochar Focus

The decision to use slow pyrolysis is almost always driven by the desire to produce high-quality biochar. This material has a range of valuable applications that make it the central focus of the technology.

High-Quality Biochar Production

The extended residence time and controlled temperature of slow pyrolysis create a biochar with high stability and a well-developed porous structure. This makes it an excellent material for carbon sequestration, as the carbon is locked into a form that will not easily decompose for hundreds or even thousands of years.

Key Applications of Biochar

The primary market for high-quality biochar is agriculture. When used as a soil amendment, it can improve water retention, increase nutrient availability, and enhance microbial activity.

Beyond agriculture, biochar is also used in filtration systems, as a building material additive, and in environmental remediation to absorb contaminants.

Understanding the Trade-offs

While effective for biochar production, slow pyrolysis comes with significant challenges and is not a one-size-fits-all solution for biomass conversion.

Output Variability is a Major Hurdle

The final properties of the biochar and wood vinegar are extremely dependent on the specific feedstock used and the precise process conditions (temperature and time). This variability makes it difficult to produce a consistent product.

This inconsistency poses a significant challenge for creating a standardized market. Without a reliable, uniform product, it is difficult to establish clear market demand and a stable price point.

Lower Liquid and Gas Yield

By design, slow pyrolysis minimizes the production of bio-oil and syngas. If your goal is to produce liquid biofuels for transportation or combustible gases for heat and power generation, slow pyrolysis is an inefficient and inappropriate choice. For those applications, fast pyrolysis or gasification are far more suitable.

Making the Right Choice for Your Goal

Selecting the right thermal conversion technology depends entirely on your desired end product.

- If your primary focus is producing a stable, solid carbon product for soil amendment or carbon sequestration: Slow pyrolysis is the optimal technology because it is specifically designed to maximize biochar yield and quality.

- If your primary focus is generating liquid biofuels (bio-oil) from biomass: You should choose fast pyrolysis, which uses rapid heating to maximize the liquid fraction.

- If your primary focus is producing a combustible gas (syngas) for electricity or heat: Gasification is the correct process, as it is optimized to convert the majority of the feedstock into gaseous products.

Ultimately, your decision must be guided by a clear understanding of your target output and the economic viability of that product in your specific market.

Summary Table:

| Feature | Description |

|---|---|

| Process Goal | Maximize production of stable, solid biochar |

| Typical Temperature Range | 300°C to 600°C |

| Heating Rate | Slow and gradual |

| Residence Time | Long (several hours) |

| Primary Product | Biochar (solid carbon) |

| Key Byproduct | Wood vinegar (pyroligneous acid) |

| Best For | Agriculture, carbon sequestration, soil amendment |

Ready to transform your biomass into high-value biochar? KINTEK specializes in laboratory equipment and consumables for advanced pyrolysis research and development. Whether you're optimizing process conditions or scaling up production, our solutions help you achieve consistent, high-quality results. Contact our experts today to discuss how we can support your biochar and pyrolysis projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is the sputtering yield of a target? A Guide to Controlling Thin-Film Deposition Efficiency

- What is the aim of sintering? Transform Powder into High-Performance Components

- What is the use of filter press in oil industry? Transform Waste Sludge into Recovered Revenue

- What is the two step sintering method? Achieve High Density with Fine Grain Structure

- Is pulsed DC sputtering better than DC sputtering? A Guide to Arc-Free Deposition

- What is the thermal property of graphite? Mastering Extreme Heat Management

- Can incubator be used for drying? Avoid damaging your samples and equipment

- What are the basics of an electric arc furnace? A Guide to Efficient Metal Recycling