At their core, sputtering and thermal evaporation are two distinct methods for creating ultra-thin films on a surface. Sputtering is a kinetic process that uses energized plasma ions to physically knock atoms from a source material onto a substrate, like a microscopic sandblaster. In contrast, thermal evaporation is a thermodynamic process that involves heating a material in a vacuum until it turns into a vapor, which then condenses onto a cooler substrate to form a film.

The fundamental difference lies in how atoms are liberated from the source material. Sputtering uses physical impact (kinetic energy), resulting in durable, high-adhesion films, while thermal evaporation uses heat (thermal energy), which is faster but typically produces films with lower density and weaker adhesion.

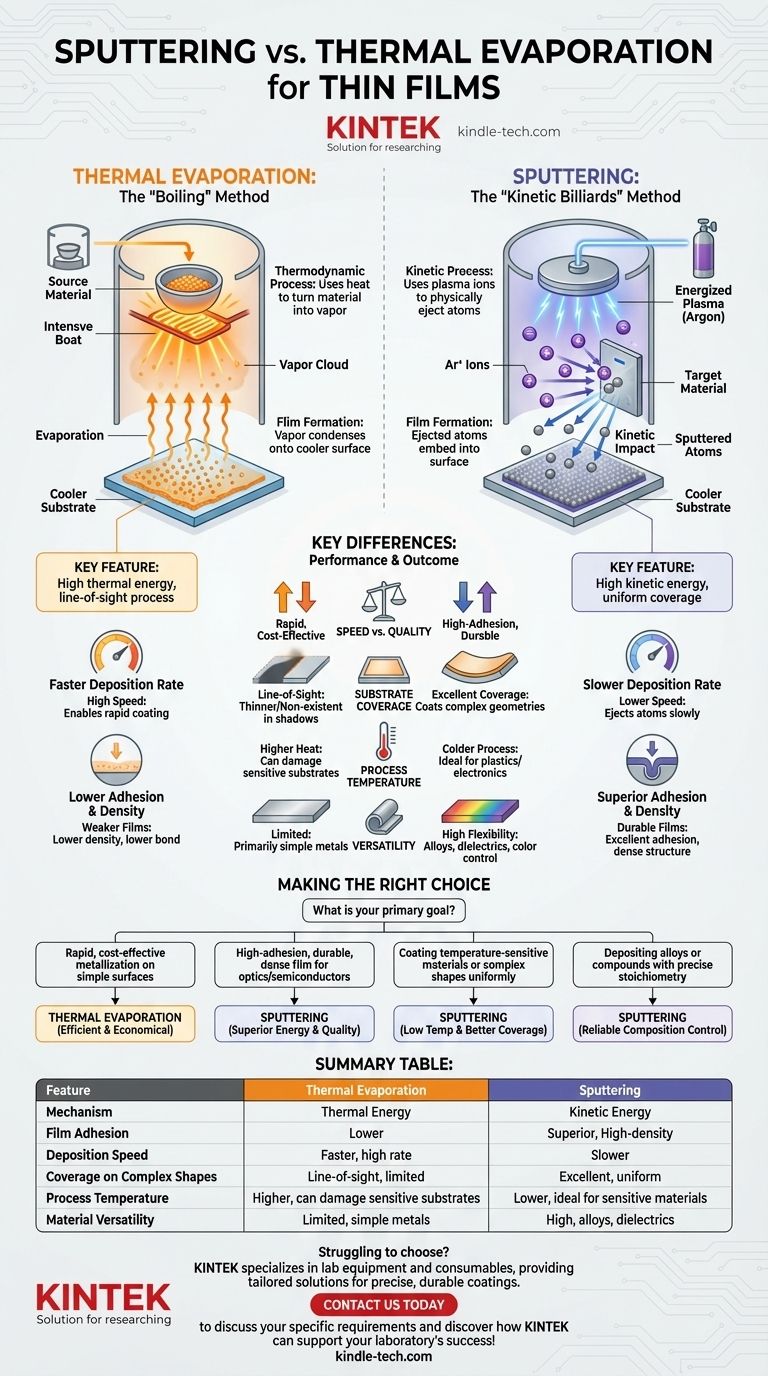

How Each Process Works: A Conceptual Breakdown

Understanding the mechanism of each technique reveals why their results are so different. They represent two fundamentally different approaches to achieving the same goal: moving atoms from a source to a target.

Thermal Evaporation: The "Boiling" Method

In thermal evaporation, a source material (often pellets) is placed in a high-vacuum chamber. A component, like a resistive boat or coil, passes a strong electrical current through the material.

This current generates intense heat, causing the material to melt and then evaporate, turning directly into a gas. These gaseous atoms travel in a straight line through the vacuum until they contact the cooler substrate, where they condense and build up to form a thin film.

Sputtering: The "Kinetic Billiards" Method

Sputtering also occurs in a vacuum chamber, but it introduces an inert gas, typically argon. An electric field energizes this gas, creating a plasma.

Positively charged argon ions from the plasma are accelerated with high energy toward the negatively charged source material, known as the "target."

These ions collide with the target, transferring their momentum and physically knocking off or "sputtering" atoms from the source. These ejected atoms then travel and deposit onto the substrate, forming a dense and uniform film.

Key Differences in Performance and Outcome

The choice between sputtering and thermal evaporation is dictated by the specific requirements of the final film, as each method excels in different areas.

Film Adhesion and Density

Sputtered atoms have significantly higher kinetic energy when they arrive at the substrate compared to evaporated atoms. This high energy allows them to embed more effectively into the surface, resulting in superior adhesion and a denser, more durable film.

Deposition Rate and Speed

Thermal evaporation is generally the faster process. By increasing the heat, it can produce a robust vapor stream, enabling high deposition rates and shorter run times. Sputtering ejects atoms or small clusters more slowly, resulting in lower deposition rates.

Substrate Coverage and Uniformity

Sputtering provides better coating coverage for substrates with complex geometries. The sputtered atoms scatter more within the chamber, allowing them to coat surfaces not in the direct line of sight of the source. Evaporation is primarily a line-of-sight process, which can lead to thinner or non-existent coatings in shadowed areas.

Process Temperature

Sputtering is considered a "colder" process than thermal evaporation. This makes it ideal for coating temperature-sensitive substrates, such as plastics or certain electronic components, that could be damaged by the high heat required for evaporation.

Understanding the Trade-offs

Neither method is universally superior; they represent a classic engineering trade-off between speed and quality.

The Speed vs. Quality Compromise

The core decision comes down to this: thermal evaporation offers speed and efficiency, while sputtering offers quality and durability. For applications where film robustness is critical, the slower rate of sputtering is a necessary price to pay for superior adhesion and density.

Material and Color Versatility

Sputtering offers greater flexibility. It can deposit a wide range of materials, including alloys and dielectrics, while preserving their original composition. It also allows for color versatility through process modulation. Thermal evaporation is often limited to the true color of the source material (e.g., aluminum) and is less suitable for complex alloys where elements may evaporate at different rates.

Making the Right Choice for Your Application

Selecting the correct deposition method requires a clear understanding of your primary goal for the thin film.

- If your primary focus is rapid, cost-effective metallization on simple surfaces: Thermal evaporation is the more efficient and economical choice.

- If your primary focus is a high-adhesion, durable, and dense film for optics or semiconductors: Sputtering is the superior method due to the higher energy of the deposited atoms.

- If your primary focus is coating temperature-sensitive materials or complex shapes uniformly: Sputtering's lower process temperature and better step coverage make it the definitive choice.

- If your primary focus is depositing alloys or compounds with precise stoichiometry: Sputtering is more reliable and ensures the resulting film accurately reflects the source material.

Ultimately, your choice is a strategic decision that balances the need for deposition speed against the demand for final film quality and performance.

Summary Table:

| Feature | Thermal Evaporation | Sputtering |

|---|---|---|

| Mechanism | Thermal energy (heating) | Kinetic energy (plasma impact) |

| Film Adhesion | Lower | Superior, high-density |

| Deposition Speed | Faster, high rate | Slower |

| Coverage on Complex Shapes | Line-of-sight, limited | Excellent, uniform |

| Process Temperature | Higher, can damage sensitive substrates | Lower, ideal for sensitive materials |

| Material Versatility | Limited, simple metals | High, alloys, dielectrics |

Struggling to choose between sputtering and thermal evaporation for your lab's thin-film needs? KINTEK specializes in lab equipment and consumables, providing tailored solutions for precise, durable coatings. Whether you need rapid metallization or high-adhesion films for sensitive substrates, our experts can help you select the right deposition system to enhance your research and production efficiency. Contact us today to discuss your specific requirements and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings