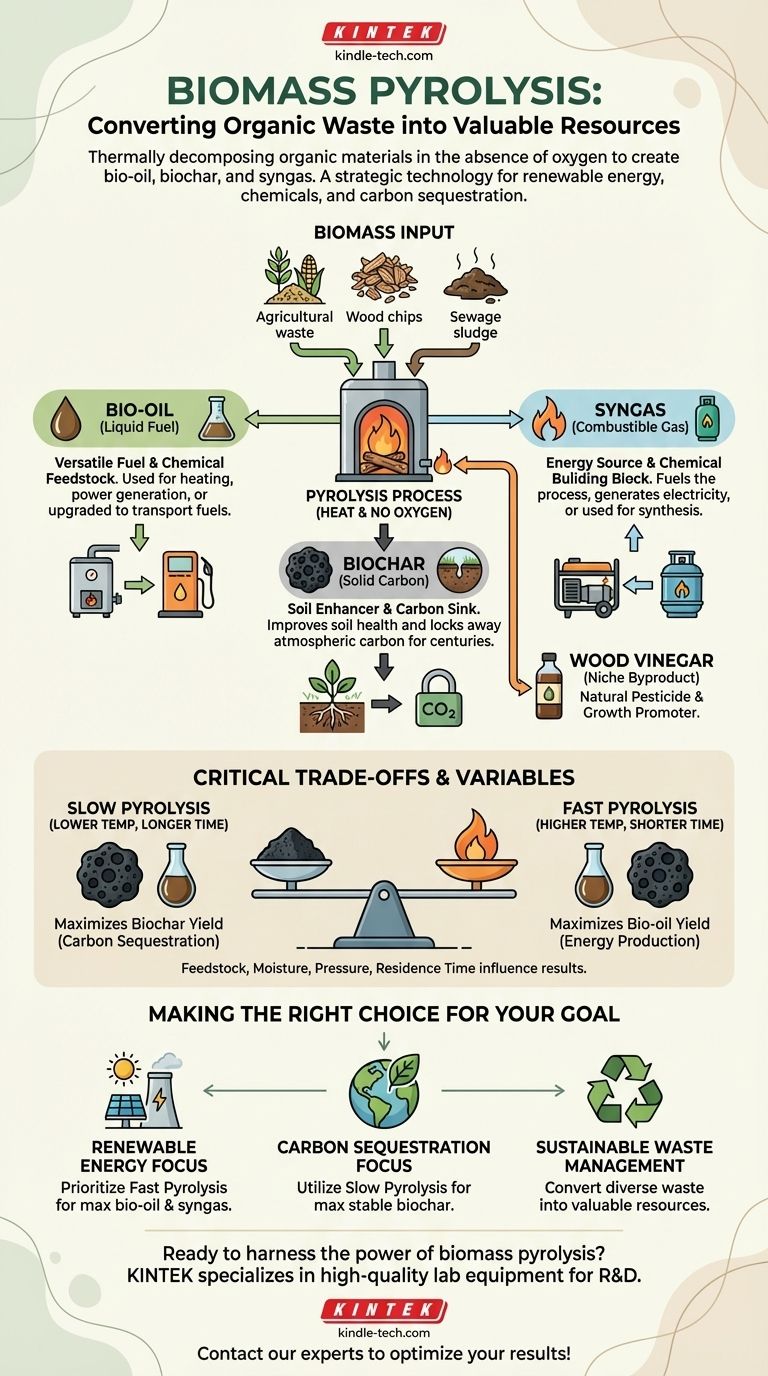

In short, the primary application of biomass pyrolysis is to thermally decompose organic materials—such as agricultural waste, wood, or sewage sludge—in the absence of oxygen. This process transforms low-value biomass into a portfolio of high-value products: a liquid fuel called bio-oil, a carbon-rich solid known as biochar, and a combustible non-condensable gas (syngas).

Biomass pyrolysis is not merely a waste-disposal method; it is a strategic technology for resource conversion. It provides a practical pathway to create renewable energy, valuable chemicals, and soil amendments from organic waste, while also offering a significant opportunity for carbon sequestration.

The Core Outputs of Biomass Pyrolysis

Pyrolysis breaks down complex organic polymers into simpler, more useful substances. The specific yield of each product depends heavily on the process conditions.

Bio-oil: A Versatile Liquid Fuel

Bio-oil is a dark, dense liquid often referred to as pyrolysis oil. It can be used directly in specialized boilers and furnaces for heating or electricity generation.

With further refining, bio-oil can be upgraded into transportation fuels like gasoline and diesel or serve as a feedstock for producing specialty chemicals, reducing our reliance on crude oil.

Biochar: A Powerful Soil Enhancer and Carbon Sink

Biochar is the stable, carbon-rich solid that remains after pyrolysis. Its porous structure makes it an excellent soil conditioner, improving water retention, nutrient availability, and soil structure.

Crucially, the carbon in biochar is highly stable and resists decomposition for centuries. When added to soil, it effectively locks away atmospheric carbon that was captured by the biomass, making it a powerful tool for carbon sequestration.

Syngas: Fuel for the Process and Beyond

The non-condensable gases produced, collectively known as syngas, are combustible. This gas is often captured and used to provide the heat required for the pyrolysis process itself, creating a self-sustaining energy loop.

Excess syngas can also be used to generate electricity or as a chemical building block for other processes.

Wood Vinegar: A Niche Byproduct

A watery condensate, often called wood vinegar or pyroligneous acid, is also collected. It has applications in agriculture as a natural pesticide and plant growth promoter, as well as in other niche chemical industries.

Understanding the Feedstock: What Can Be Processed?

The versatility of pyrolysis allows it to process an exceptionally wide range of organic materials that would otherwise be considered waste.

Agricultural and Forestry Residues

This is the most common category of feedstock. It includes everything from corn stalks, rice husks, and coffee shells to wood chips, sawdust, tree bark, and bamboo.

Industrial and Municipal Wastes

Pyrolysis provides an effective treatment method for organic industrial wastes, such as sewage sludge, and the organic fraction of municipal solid waste, like garden trimmings and food waste.

The Critical Trade-offs and Variables

The output of a pyrolysis plant is not fixed. It is a direct result of carefully controlled process variables. Understanding these trade-offs is essential for optimizing the process for a specific goal.

The Impact of Temperature and Speed

This is the most significant control lever. Slow pyrolysis, which involves lower temperatures (around 400°C) and longer residence times, maximizes the yield of biochar.

Conversely, fast pyrolysis, which uses higher temperatures (above 500°C) and very short residence times, is optimized to maximize the production of bio-oil.

The Role of Feedstock Characteristics

The type and condition of the biomass are critical. Higher moisture content requires more energy to evaporate the water before pyrolysis can begin, reducing overall efficiency. The chemical composition of the feedstock also influences the final product distribution.

The Influence of Pressure and Residence Time

Along with temperature, the pressure inside the reactor and the residence time (how long the material is heated) are fine-tuned to favor the creation of either liquid, solid, or gas products. Proper control is crucial to achieve the desired outcome efficiently.

Making the Right Choice for Your Goal

To apply pyrolysis effectively, you must first define your primary objective. The process can be tailored to meet different strategic needs, from energy generation to climate mitigation.

- If your primary focus is renewable energy production: You should prioritize fast pyrolysis conditions to maximize the yield of combustible bio-oil and syngas.

- If your primary focus is carbon sequestration and soil improvement: You should utilize slow pyrolysis to maximize the production of stable, long-lasting biochar.

- If your primary focus is sustainable waste management: Pyrolysis offers a flexible solution to convert diverse waste streams into valuable resources, drastically reducing landfill burden and creating a circular economy.

By understanding its core principles and controllable variables, you can leverage biomass pyrolysis as a powerful tool to achieve specific environmental and economic goals.

Summary Table:

| Product | Primary Application | Key Benefit |

|---|---|---|

| Bio-oil | Renewable fuel, chemical feedstock | Reduces reliance on crude oil |

| Biochar | Soil enhancement, carbon sequestration | Locks away carbon for centuries |

| Syngas | Process heat, electricity generation | Creates self-sustaining energy loop |

Ready to harness the power of biomass pyrolysis in your lab or operation?

KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and development. Whether you're optimizing bio-oil yield or studying biochar properties, our reliable solutions help you achieve precise, reproducible results.

Contact our experts today to discuss how we can support your sustainable energy and waste management goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Three-dimensional electromagnetic sieving instrument

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the importance of a high-temperature electric firing kiln in the final preparation of dense refractory bricks?

- What is the composition of wood pyrolysis gas? A Guide to Syngas Production & Control

- What is the process of rotary kiln? Achieve Precise Industrial Material Transformation

- What is the principle of a fluidized bed reactor? Achieve Superior Mixing and Heat Transfer

- What is the difference between regeneration and reactivation of carbon? Clarifying Key Terminology

- What is the temperature range of a rotary kiln incinerator? Optimize Waste Destruction & Efficiency

- What are the parameters of a rotary kiln? Mastering Control for Optimal Process Results

- What is the structure of a rotary kiln? A Detailed Breakdown of Its Core Components