In nearly every advanced industry, vacuum technology is an invisible yet essential tool that enables the creation of modern products. It is the foundational process for manufacturing the semiconductors in your phone, preserving the food you eat, and developing new pharmaceuticals. Its applications are not about creating "emptiness" for its own sake, but about precisely removing atmospheric gases to control an environment and enable processes that are otherwise impossible.

The fundamental value of industrial vacuum is not suction, but environmental control. By removing air and other particles, vacuum systems create a highly controlled space that prevents contamination, eliminates physical obstructions, and alters the fundamental physical properties of materials.

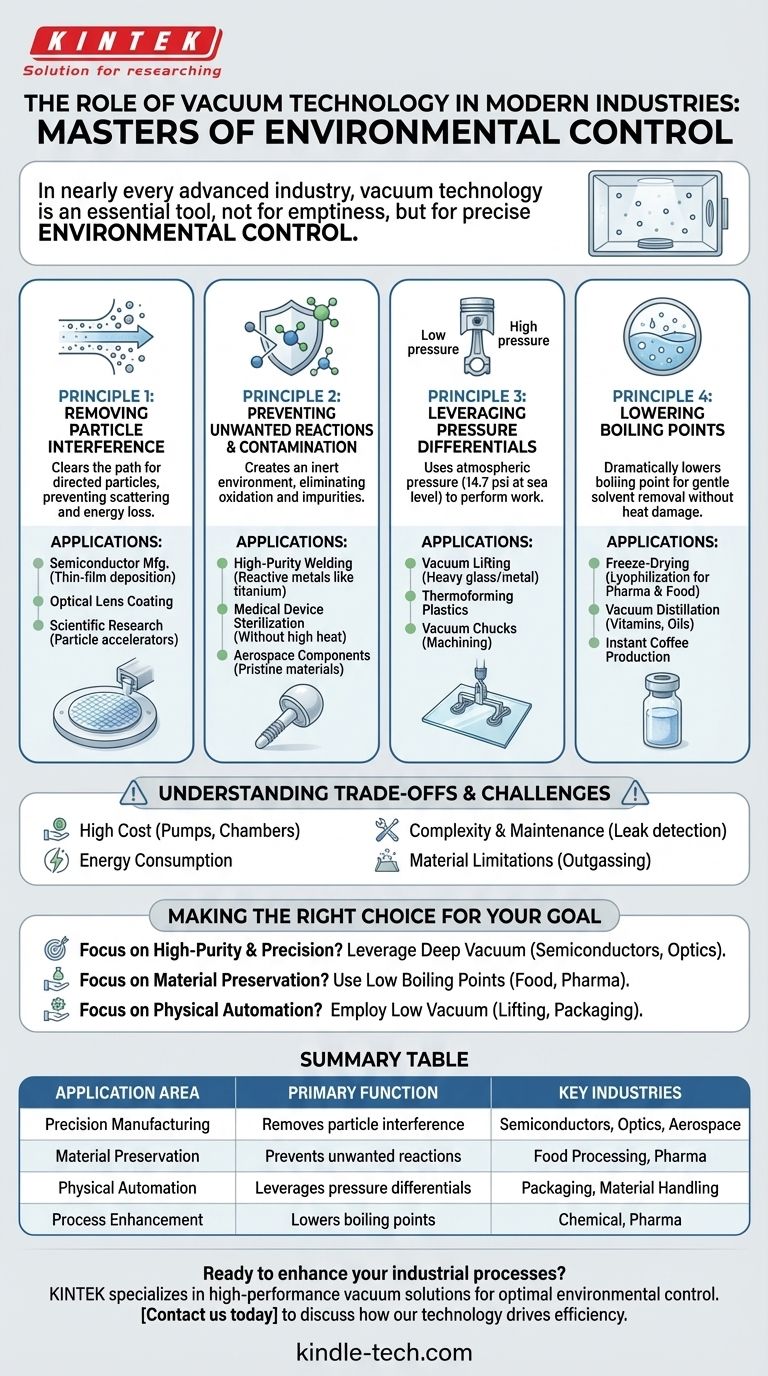

The Core Principles Driving Vacuum Applications

To understand where vacuum is used, you must first understand why it is used. Industrial applications are almost always based on one of four fundamental principles.

Principle 1: Removing Particle Interference

Many high-tech processes involve directing tiny particles—ions, electrons, or molecules—from a source to a target.

Atmospheric gas molecules act as a dense field of obstacles, causing these directed particles to scatter and lose energy, ruining the process.

A vacuum clears this path. This ensures processes like semiconductor manufacturing (thin-film deposition), optical lens coating, and scientific research (particle accelerators) can function with absolute precision.

Principle 2: Preventing Unwanted Reactions and Contamination

The air around us is chemically reactive, containing oxygen, water vapor, and various contaminants.

These substances can cause unwanted oxidation (like rust), introduce impurities, or otherwise degrade materials during sensitive processes.

By removing the atmosphere, a vacuum creates an inert environment. This is critical for high-purity welding of reactive metals like titanium, sterilizing medical devices without high heat, and producing pristine materials for aerospace components.

Principle 3: Leveraging Pressure Differentials

This is the most intuitive application of vacuum—using atmospheric pressure to perform work.

When you remove air from one side of an object, the normal atmospheric pressure on the other side (about 14.7 psi at sea level) pushes on it with immense force.

This principle is the basis for vacuum lifting systems that move heavy glass or metal plates, thermoforming plastics into packaging, and vacuum chucks that hold delicate parts for machining. It is simple, powerful, and clean.

Principle 4: Lowering Boiling Points

The boiling point of a liquid is not fixed; it depends on the pressure above it. Lowering the pressure dramatically lowers the temperature at which a liquid boils.

This allows for the removal of water or other solvents from a product without using high heat, which could destroy it.

This is the key to freeze-drying (lyophilization) in the pharmaceutical and food industries, preserving sensitive biological samples and creating instant coffee. It is also used for vacuum distillation to purify temperature-sensitive vitamins and oils.

Understanding the Trade-offs and Challenges

Implementing vacuum technology is not a simple decision. It involves significant investment and operational complexity that must be weighed against its benefits.

The Cost of a Controlled Environment

Vacuum systems are expensive. The initial capital outlay for high-quality pumps, chambers, valves, and gauges can be substantial, especially for systems requiring high or ultra-high vacuum levels.

Energy Consumption

Generating and maintaining a vacuum is an energy-intensive process. Pumps often need to run continuously to overcome tiny leaks and the outgassing of materials within the chamber, leading to significant ongoing operational costs.

Complexity and Maintenance

Vacuum systems are not "set it and forget it" equipment. They require specialized knowledge to design, operate, and maintain.

Leak detection is a constant concern, as even a microscopic leak can render a high-vacuum process useless. Regular maintenance of pump oil, seals, and sensors is mandatory.

Material Limitations (Outgassing)

Not all materials behave well in a vacuum. Plastics, composites, and certain adhesives can slowly release trapped gases—a phenomenon called outgassing.

This can contaminate the vacuum environment, making it impossible to reach the required pressure and potentially ruining sensitive products like optical lenses or semiconductors.

Making the Right Choice for Your Goal

The right vacuum application depends entirely on the industrial outcome you need to achieve.

- If your primary focus is high-purity manufacturing and precision: Leverage deep vacuum systems to eliminate particle interference and prevent reactions, essential for semiconductors, optics, and aerospace.

- If your primary focus is material preservation and stability: Use vacuum's ability to lower boiling points and remove reactive gases for food processing, pharmaceutical production, and chemical purification.

- If your primary focus is physical automation and handling: Employ low-vacuum systems to create powerful pressure differentials for lifting, forming, holding, and packaging applications.

Ultimately, mastering vacuum technology is about understanding which atmospheric element you need to remove to achieve your specific industrial outcome.

Summary Table:

| Application Area | Primary Function | Key Industries |

|---|---|---|

| Precision Manufacturing | Removes particle interference for accuracy | Semiconductors, Optics, Aerospace |

| Material Preservation | Prevents unwanted reactions and contamination | Food Processing, Pharmaceuticals |

| Physical Automation | Leverages pressure differentials for work | Packaging, Material Handling |

| Process Enhancement | Lowers boiling points for gentle processing | Chemical, Pharmaceutical |

Ready to enhance your industrial processes with precision vacuum solutions? KINTEK specializes in high-performance lab equipment and consumables, providing reliable vacuum systems tailored to your laboratory's unique needs. Whether you're in semiconductor manufacturing, pharmaceuticals, or materials research, our expertise ensures optimal environmental control for contamination-free results. Contact us today to discuss how our vacuum technology can drive efficiency and innovation in your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the temperature of the heat of the arc in arc welding? Mastering Extreme Heat for Perfect Welds

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- What temperature is hardening heat treatment? Master the Critical Range for Superior Steel Hardness

- How does pyrolysis of plastic work? Unlock Value from Waste Plastic

- What is the primary function of a vacuum resistance furnace in the recovery of hazardous magnesium waste?

- How do the parameter controls of a vacuum drying oven affect the performance of electrodes? Optimize Your Lab Results

- How are pyrolysis reactors heated? Choosing the Right Method for Your Process

- What role does a precision temperature-controlled furnace play in the PWHT of P91/Incoloy 800HT joints? Achieve Integrity