At its core, vacuum hardening offers unparalleled control over the heat treatment process. By heating metal components in an oxygen-free environment, it produces parts with superior material integrity, a clean and bright surface finish, and minimal dimensional distortion. This eliminates common defects and reduces the need for secondary processing steps.

The fundamental advantage of vacuum hardening is not just creating a harder part, but ensuring predictable, repeatable quality. It transforms heat treatment from a potential source of defects into a precise manufacturing step that enhances final component reliability and can even lower total production costs.

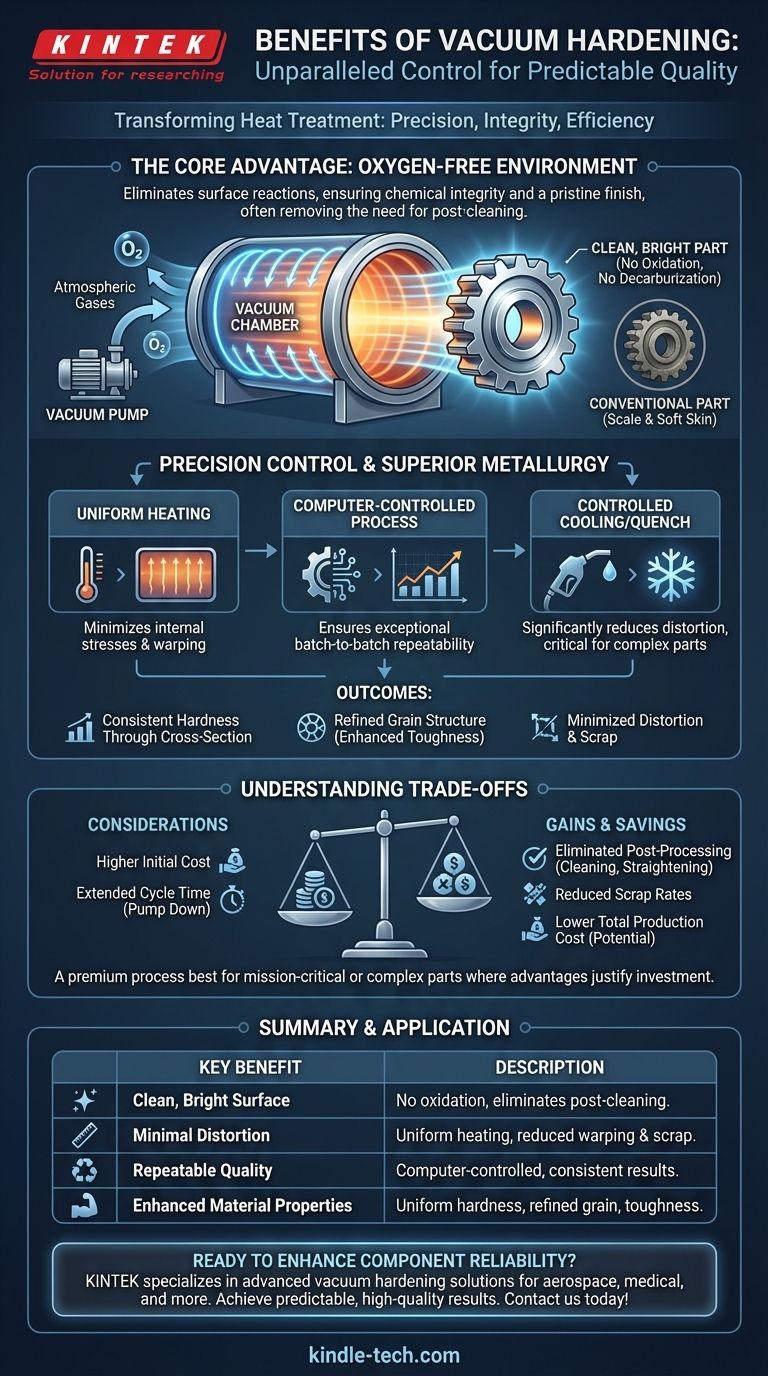

The Fundamental Advantage: An Oxygen-Free Environment

The "vacuum" in vacuum hardening is the key to its benefits. By removing atmospheric gases, primarily oxygen, from the furnace chamber, the process fundamentally changes how the metal behaves at high temperatures.

Preventing Surface Oxidation and Decarburization

At hardening temperatures, steel readily reacts with oxygen, forming a layer of scale (oxidation) on the surface. It can also lose carbon from its surface layer (decarburization), resulting in a soft, weak outer skin.

A vacuum environment eliminates the oxygen required for these reactions. This ensures the component's surface chemistry remains unaltered and free from scale.

Achieving a Chemically Pristine Surface

Because vacuum-hardened parts emerge from the furnace clean, bright, and free of scale, they often require no further mechanical or chemical cleaning.

This eliminates entire post-processing steps like sandblasting, grinding, or acid pickling, saving significant time and cost in the manufacturing workflow.

Precision Control and Repeatability

Modern vacuum furnaces are highly engineered systems that provide a level of process control that atmospheric furnaces cannot match.

Unmatched Temperature Uniformity

Vacuum furnaces offer exceptional insulation and allow for precise, uniform heating. This ensures the entire component, including complex geometries and thin sections, reaches the target temperature at the same rate.

This uniformity minimizes internal stresses that cause warping and distortion, a critical benefit for high-precision parts.

Computer-Controlled Processes

Vacuum hardening is a fully automated, computer-controlled process. All parameters—from the heating rate and soak time to the pressure and cooling quench—are precisely regulated.

This high degree of control delivers exceptional repeatability from one batch to the next, which is essential for industries like aerospace and medical devices where component consistency is non-negotiable.

Superior Metallurgical Outcomes

The combination of a clean environment and precise control directly translates to improved and more reliable material properties in the final product.

Consistent Hardness Through the Cross-Section

The process achieves the specified strength and hardness properties throughout the entire cross-section of the component, without the soft outer layer caused by surface decarburization.

Minimized Distortion and Warping

By ensuring uniform heating and controlled cooling (often using high-pressure gas quenching), vacuum hardening significantly reduces the risk of distortion.

This is critical for complex, thin-walled, or large parts where maintaining dimensional tolerance is paramount. It reduces scrap rates and eliminates costly straightening operations.

Refined Grain Structure

Proper vacuum heat treatment cycles result in a fine and uniform austenitic grain structure. This fine grain contributes directly to improved mechanical properties, such as enhanced toughness and fatigue resistance.

Understanding the Trade-offs

While powerful, vacuum hardening is not a universal solution. An objective evaluation requires acknowledging its specific costs and considerations.

Initial Cost and Complexity

Vacuum furnaces represent a significant capital investment compared to conventional atmospheric furnaces. This can translate to a higher per-piece processing cost.

The decision must be weighed against the savings from eliminated post-processing and reduced scrap rates.

Process Cycle Time

The time required to pump down the furnace to the required vacuum level can extend the overall cycle time compared to some atmospheric processes.

However, this can be offset by the complete elimination of downstream cleaning or straightening operations, potentially shortening the total door-to-door manufacturing time.

Suitability for the Application

For simple parts made from low-carbon steels where surface finish and tight tolerances are not critical, the benefits of vacuum hardening may not justify the added cost. It is a premium process best applied where its advantages directly solve a manufacturing or performance challenge.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on the component's end-use requirements and the overall manufacturing goals.

- If your primary focus is mission-critical performance and reliability: Vacuum hardening is the superior choice for its ability to produce defect-free parts with uniform, repeatable metallurgical properties.

- If your primary focus is reducing total manufacturing cost: Evaluate vacuum hardening for its potential to eliminate secondary operations like cleaning and straightening, which can deliver a lower net cost.

- If your primary focus is processing complex or thin-walled geometries: The process's minimal distortion and uniform heating make it essential for maintaining tight dimensional tolerances and avoiding scrap.

Ultimately, choosing vacuum hardening is an investment in predictable quality and final part integrity.

Summary Table:

| Key Benefit | Description |

|---|---|

| Clean, Bright Surface | No oxidation or decarburization; eliminates need for post-cleaning. |

| Minimal Distortion | Uniform heating and controlled cooling reduce warping and scrap. |

| Repeatable Quality | Computer-controlled process ensures consistent results batch-to-batch. |

| Enhanced Material Properties | Achieves uniform hardness and refined grain structure for toughness. |

Ready to enhance your component reliability and reduce manufacturing costs? KINTEK specializes in precision lab equipment, including advanced vacuum hardening solutions tailored for industries like aerospace and medical devices. Our expertise ensures you achieve predictable, high-quality results with minimal post-processing. Contact us today to discuss how our vacuum furnaces can meet your specific heat treatment needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing