Titanium PVD is not a single color, but rather a process that creates a vast spectrum of durable, decorative finishes. The most common colors range from metallic tones like gold, bronze, and black to vibrant custom hues, all achieved by precisely controlling the materials used in the coating process.

The key takeaway is that Physical Vapor Deposition (PVD) is a sophisticated coating technology, not a color itself. The final color is a highly engineered outcome determined by the specific metal vaporized and the reactive gases introduced during the process.

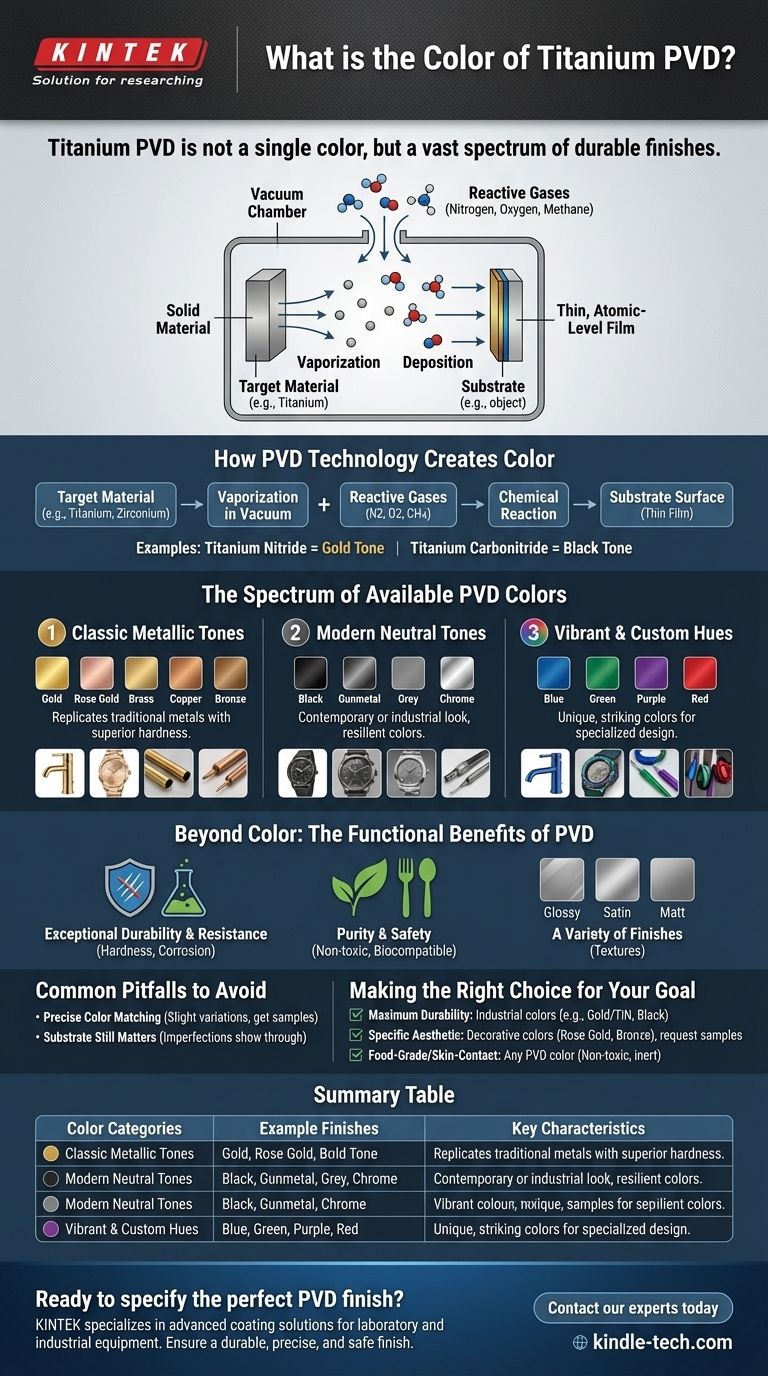

How PVD Technology Creates Color

Physical Vapor Deposition works by vaporizing a solid metal (called the "target") in a vacuum chamber and depositing it as a thin, atomic-level film onto a substrate. The color is determined by the composition of this film.

The Role of the Target Material

The base metal vaporized has the most significant impact on the final color and properties. While titanium is a common base, other metals like zirconium and chromium are also used to achieve different outcomes.

The Influence of Reactive Gases

Introducing precise amounts of reactive gases like nitrogen, oxygen, or methane derivatives into the vacuum chamber allows them to combine with the metal vapor. This creates new compounds on the substrate's surface, each with a unique color. For example, titanium nitride produces a classic gold tone, while other combinations create black, bronze, or grey.

The Spectrum of Available PVD Colors

The PVD process offers a surprisingly wide palette, allowing for significant design flexibility. These colors are generally consistent and can be applied with different surface textures.

Classic Metallic Tones

The most common PVD colors replicate traditional metals but with superior hardness. This category includes shades like Gold, Rose Gold, Brass, Copper, and Bronze.

Modern Neutral Tones

For a more contemporary or industrial look, PVD excels at producing deep, resilient neutral colors. Popular options are Black, Gunmetal, Grey, and Chrome finishes.

Vibrant and Custom Hues

With further manipulation of the process, it's possible to create more exotic and striking colors. While less common, shades like Blue, Green, Purple, and even Red can be achieved.

Beyond Color: The Functional Benefits of PVD

The reason PVD is so widely used extends far beyond its aesthetic versatility. The coating itself provides significant performance advantages.

Exceptional Durability and Resistance

PVD coatings are extremely hard and more corrosion-resistant than finishes from traditional electroplating. They exhibit excellent resistance to abrasion, scratches, and acid degradation, making them suitable for high-wear items.

Purity and Safety

The process is environmentally friendly and produces coatings of very high purity. This makes them non-toxic and biocompatible, which is why they are often used for kitchenware, as they do not affect the taste of food and are dishwasher safe.

A Variety of Finishes

Beyond the color itself, PVD coatings can be applied to achieve different surface textures. The final appearance can be specified as polished (glossy), satin, or matt to match the desired aesthetic.

Common Pitfalls to Avoid

While powerful, the PVD process has nuances that are important to understand to ensure a successful outcome.

The Challenge of Precise Color Matching

Achieving an exact color match, especially for a very specific or critical shade, can be difficult. Because the color is a result of a complex physical process, slight variations can occur. For projects requiring absolute uniformity, getting samples first is essential.

The Substrate Still Matters

PVD is an extremely thin film. While it provides the color and a hard outer layer, the final texture and smoothness of the product depend entirely on the preparation of the underlying material. An imperfect surface will still show imperfections through the PVD coating.

Making the Right Choice for Your Goal

To select the best finish, consider your primary objective.

- If your primary focus is maximum durability and wear resistance: Stick to well-established industrial PVD colors like gold (Titanium Nitride), gunmetal, or black, which have a long track record in demanding applications.

- If your primary focus is a specific aesthetic: Explore the full range of decorative colors like rose gold, bronze, or copper, but be sure to request physical samples to verify the exact shade and finish.

- If your primary focus is a food-grade or skin-contact product: You can confidently use any PVD color, as the coating is non-toxic and inert, making it a superior choice for flatware, watches, and fixtures.

Ultimately, PVD technology empowers you to choose a finish based on both aesthetic appeal and superior technical performance.

Summary Table:

| Common PVD Color Categories | Example Finishes | Key Characteristics |

|---|---|---|

| Classic Metallic Tones | Gold, Rose Gold, Bronze, Brass | Replicates traditional metals with superior hardness and wear resistance. |

| Modern Neutral Tones | Black, Gunmetal, Grey, Chrome | Offers a contemporary, industrial look with deep, resilient color. |

| Vibrant & Custom Hues | Blue, Green, Purple, Red | Provides unique, striking colors for specialized design applications. |

Ready to specify the perfect PVD finish for your product?

The right coating balances aesthetic appeal with technical performance. At KINTEK, we specialize in advanced coating solutions for laboratory and industrial equipment. Our expertise ensures you get a durable, precise, and safe finish tailored to your specific needs—whether for high-wear components, medical devices, or consumer products.

Contact our experts today to discuss your project and request material samples. Let's engineer the ideal finish together.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating