At its core, Chemical Vapor Deposition (CVD) is a process that builds a high-performance, solid thin film onto a surface from a gas. It works by introducing a volatile precursor gas into a reaction chamber, heating it until it decomposes or reacts, and allowing the resulting solid material to deposit uniformly onto a target object, known as a substrate. This method creates exceptionally pure and dense coatings atom by atom.

The central principle of CVD is using a chemical reaction in a gaseous state to create a superior solid coating. This allows for the creation of highly uniform, pure, and well-bonded thin films on even the most complex surfaces, a feat difficult to achieve with other methods.

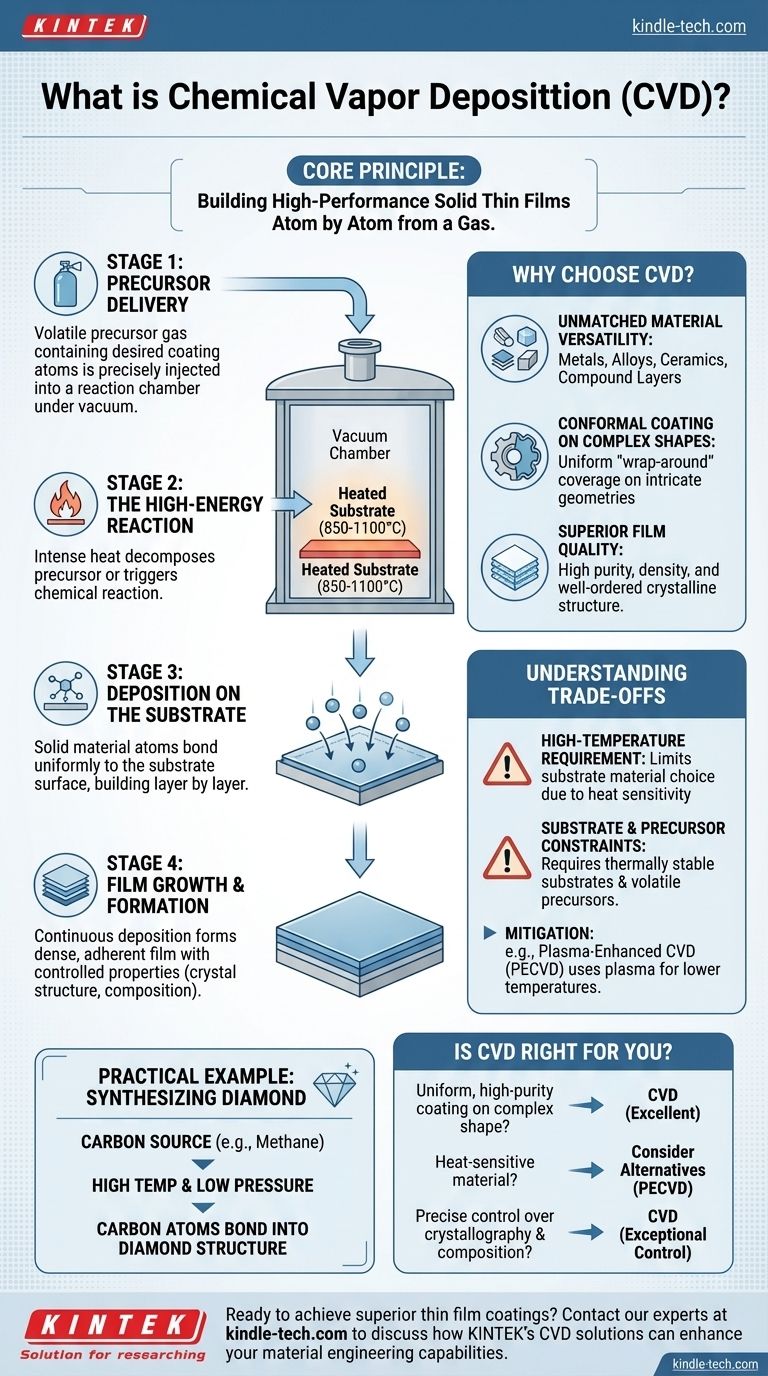

Deconstructing the CVD Process

To understand how CVD works, we can break it down into four fundamental stages that occur within a controlled environment. The entire system is engineered to manage the flow of gases, temperature, and pressure with high precision.

Stage 1: Precursor Delivery

The process begins with the precursor, a chemical compound in a volatile (gaseous) state. This precursor contains the atoms of the desired coating material.

This gas is precisely injected into a reaction chamber, which is typically held under a vacuum to remove unwanted air and impurities.

Stage 2: The High-Energy Reaction

Inside the chamber, the substrate is heated to a very high temperature, generally between 850-1100°C.

This intense heat provides the necessary energy to trigger a chemical change, causing the precursor gas to either decompose or react with other gases in the chamber.

Stage 3: Deposition on the Substrate

As the precursor gas reacts, the desired solid material is formed. These newly freed atoms or molecules then travel and bond to the surface of the heated substrate.

This deposition occurs evenly across all exposed surfaces of the substrate, building up the coating one layer of atoms at a time.

Stage 4: Film Growth and Formation

Over time, this continuous deposition forms a thin, dense, and highly adherent film. The process parameters—such as temperature, pressure, and gas composition—are carefully controlled to dictate the film's final properties.

For example, this control allows for the creation of films with specific crystal structures, grain sizes, or chemical makeups.

Why Choose Chemical Vapor Deposition?

The unique nature of its "bottom-up" atomic assembly gives CVD several powerful advantages, making it the preferred method for many advanced applications.

Unmatched Material Versatility

CVD is not limited to one type of material. It can be used to deposit a vast range of coatings, including pure metals, alloys, ceramics, and other compound layers.

Conformal Coating on Complex Shapes

Because the precursor is a gas, it can flow into and around intricate geometries. This results in an exceptionally uniform, "wrap-around" coating that perfectly covers complex surfaces, a key advantage over line-of-sight methods.

Superior Film Quality

The films produced by CVD are known for their high purity and density. The controlled, high-temperature environment promotes the formation of well-ordered crystalline structures with low residual stress.

Understanding the Trade-offs of CVD

Despite its advantages, CVD is not a universal solution. Its operational requirements introduce specific limitations that must be considered.

The High-Temperature Requirement

The most significant limitation is the extremely high temperature needed for the chemical reaction. Many potential substrate materials simply cannot withstand this heat without melting, deforming, or losing their essential properties.

Substrate and Precursor Constraints

The choice of substrate is limited to materials that are thermally stable at the required deposition temperature. Furthermore, the coating material must be available in the form of a suitable volatile precursor, which is not always possible.

Mitigating the Heat Challenge

To overcome the temperature barrier, modified versions of CVD have been developed. Technologies like plasma-enhanced CVD (PECVD) use plasma instead of just heat to energize the precursor gas, allowing for deposition at much lower temperatures.

A Practical Example: Synthesizing Diamond

CVD is a leading method for creating synthetic diamonds for industrial tools and electronics.

The Carbon Source

A carbon-containing gas, such as methane, is introduced into the chamber along with hydrogen gas.

The Role of Temperature and Pressure

The high temperature cracks the methane and hydrogen molecules, creating reactive carbon atoms. A low-pressure environment ensures these reactive atoms have a long, clear path to the substrate, maximizing collision efficiency and preventing contamination.

Building the Diamond Film

These activated carbon atoms bond to the substrate and to each other, arranging themselves into the strong carbon-carbon bonds that form the crystalline structure of diamond.

Is CVD the Right Choice for Your Application?

Choosing a deposition technique requires aligning its capabilities with your primary goal.

- If your primary focus is a uniform, high-purity coating on a complex shape: CVD is an outstanding choice due to its superior conformal coverage and film quality.

- If your primary focus is coating a heat-sensitive material (like plastic or certain alloys): Traditional high-temperature CVD is unsuitable, and you must consider lower-temperature alternatives like PECVD or other deposition methods.

- If your primary focus is precise control over the film's crystallography and composition: CVD offers an exceptional level of control through fine-tuning of its process parameters.

Ultimately, Chemical Vapor Deposition empowers engineers to construct materials from the atom up, creating advanced surfaces with precisely engineered properties.

Summary Table:

| CVD Stage | Key Process | Purpose |

|---|---|---|

| Stage 1: Precursor Delivery | Introduction of volatile gas into a vacuum chamber | To supply coating material atoms in gaseous form |

| Stage 2: High-Energy Reaction | Heating substrate to 850-1100°C | To decompose precursor gas and activate chemical reactions |

| Stage 3: Deposition | Bonding of solid material atoms to substrate surface | To build coating layer by layer with uniform coverage |

| Stage 4: Film Growth | Controlled deposition over time | To form dense, adherent films with specific properties |

Ready to achieve superior thin film coatings for your laboratory applications? KINTEK specializes in providing advanced lab equipment and consumables for precise Chemical Vapor Deposition processes. Our solutions help you create high-purity, uniform coatings on even the most complex substrates. Contact our experts today to discuss how our CVD technology can enhance your material engineering capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings