In essence, Chemical Vapor Deposition (CVD) is a synthesis technique used to deposit a solid, high-purity thin film or coating onto a surface. The process works by introducing precursor gases into a reaction chamber, where they decompose and react on a heated object, known as a substrate, to form the desired material layer by layer. This method is fundamental to industries like semiconductor manufacturing and advanced materials science.

CVD is not just a coating method; it is a precise, atom-by-atom construction process. By carefully controlling temperature, pressure, and gas chemistry, CVD allows for the creation of highly pure, dense, and uniform materials that are often impossible to produce with simpler melting or mechanical techniques.

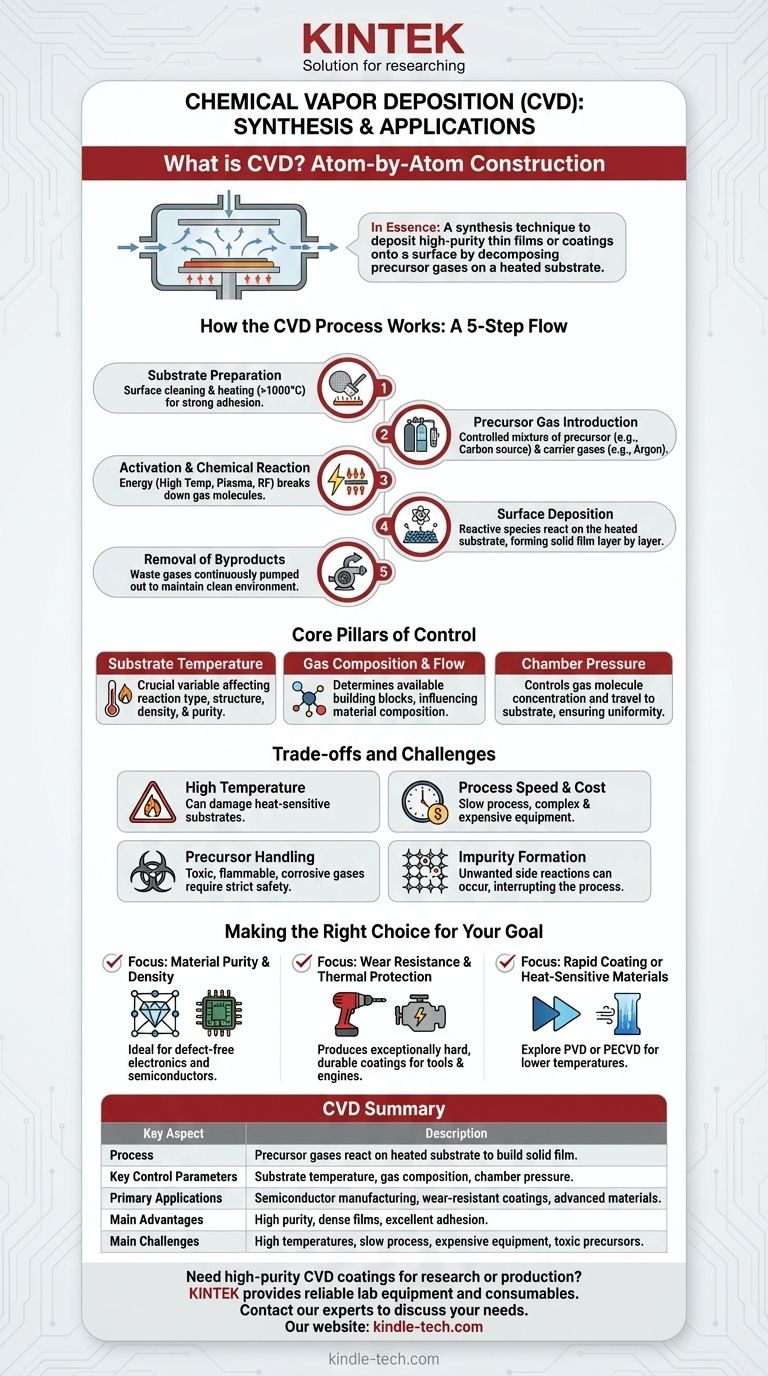

How the CVD Process Works: A Step-by-Step Breakdown

To truly understand CVD, you must see it as a sequence of controlled events. Each step is critical for the final quality of the film.

1. Substrate Preparation

The process begins with the substrate, which is the material to be coated (e.g., a silicon wafer or a metal tool). It is placed inside the reaction chamber.

The substrate is often cleaned and heated, sometimes to temperatures exceeding 1000°C. This heating prepares the surface chemistry and removes impurities, ensuring the final film will adhere strongly.

2. Introduction of Precursor Gases

A carefully controlled mixture of gases is introduced into the chamber. These include precursor gases, which contain the atoms of the material you wish to deposit (like carbon for diamond).

These are often mixed with a carrier gas, an inert gas like argon or nitrogen, which helps transport the precursors and control their concentration.

3. Activation and Chemical Reaction

Energy is applied to the chamber to initiate a chemical reaction. Most commonly, this energy is high temperature, which causes the precursor gas molecules to break apart into highly reactive atoms or radicals.

In some variations, other energy sources like an RF plasma field or hot filaments are used to activate the gases, which can allow for lower process temperatures.

4. Surface Deposition

The reactive gas species diffuse through the chamber and make contact with the heated substrate. The substrate's surface acts as a catalyst, promoting chemical reactions that were not possible in the gas phase alone.

As these reactions occur, the solid material forms directly on the substrate surface, building a dense and uniform film atom by atom.

5. Removal of Byproducts

The chemical reactions create both the desired solid film and unwanted gaseous byproducts. These waste gases are continuously pumped out of the chamber to maintain a controlled environment and prevent contamination.

The Core Pillars of Control in CVD

The quality and properties of the deposited film are not accidental; they are the direct result of precise control over several key parameters.

Substrate Temperature

This is arguably the most crucial variable. The temperature of the substrate dictates the type of chemical reactions that can occur on its surface, directly influencing the film's structure, density, and purity.

Gas Composition and Flow

The exact recipe of precursor and carrier gases, along with their flow rate, determines the building blocks available for the film. Changing the mix can change the composition of the final material.

Chamber Pressure

Pressure affects the concentration of gas molecules and how they travel to the substrate. CVD is often performed at specific vacuum pressures to ensure a clean environment and uniform deposition.

Understanding the Trade-offs and Challenges

While incredibly powerful, CVD is not a universal solution. It comes with specific requirements and limitations that must be considered.

High Temperature Requirements

Traditional thermal CVD requires very high temperatures. This can damage or warp certain substrate materials, limiting its application to things that can withstand the heat.

Process Speed and Cost

CVD can be a slow process, sometimes taking hours or even days to grow a film of the desired thickness. The specialized equipment (vacuum chambers, high-temperature furnaces, gas handling systems) is also complex and expensive.

Handling of Precursor Chemicals

The gases used as precursors are often toxic, flammable, or corrosive. This necessitates stringent safety protocols and specialized handling equipment, adding to the operational complexity.

Formation of Impurities

If conditions are not perfectly optimized, unwanted side reactions can occur. For example, during diamond synthesis, graphite (a different form of carbon) can form and must be periodically removed, interrupting the process.

Making the Right Choice for Your Goal

CVD is a powerful but specific tool. Its suitability depends entirely on your project's end goal.

- If your primary focus is material purity and density: CVD is ideal for creating the defect-free, crystalline structures required for high-performance electronics and semiconductors.

- If your primary focus is wear resistance or thermal protection: CVD produces exceptionally hard and strongly bonded coatings that can significantly extend the life of cutting tools and engine components.

- If your primary focus is rapid coating or working with heat-sensitive materials: You should explore alternatives like Physical Vapor Deposition (PVD) or Plasma-Enhanced CVD (PECVD), which can operate at lower temperatures.

Ultimately, understanding CVD is to understand a method of building materials from the atoms up, offering unparalleled control for the most demanding applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Precursor gases react on a heated substrate to build a solid film layer by layer. |

| Key Control Parameters | Substrate temperature, gas composition, chamber pressure. |

| Primary Applications | Semiconductor manufacturing, wear-resistant coatings, advanced materials. |

| Main Advantages | High purity, dense and uniform films, excellent adhesion. |

| Main Challenges | High temperatures, slow process, expensive equipment, handling toxic precursors. |

Need a high-purity coating or thin film for your research or production?

The precise control offered by CVD processes is essential for creating the advanced materials that power modern technology. KINTEK specializes in providing the lab equipment and consumables needed for reliable and efficient CVD synthesis.

Our expertise can help you achieve the material purity and performance your project demands. Contact our experts today to discuss how we can support your laboratory's specific needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- How does chemical vapor deposition work for carbon nanotubes? A Guide to Controlled Synthesis

- What does process robustness or productivity refer to in deposition systems? Optimize Your Manufacturing Workflow

- What effects the deposition rate? Master the Key Variables for Optimal Sputtering

- What is the function of high-vacuum systems in CVD? Precision Control for Superior Oxidation Catalysts

- What is the precursor for CNT preparation? Choosing the Right Carbon Source for Quality & Yield

- Why argon is used in sputtering process? The Perfect Balance of Physics and Economics

- What are the applications of MOCVD? Unlocking High-Performance LEDs, Lasers, and Electronics

- What are the advantages and disadvantages of sputtering techniques? Achieve Superior Thin-Film Deposition