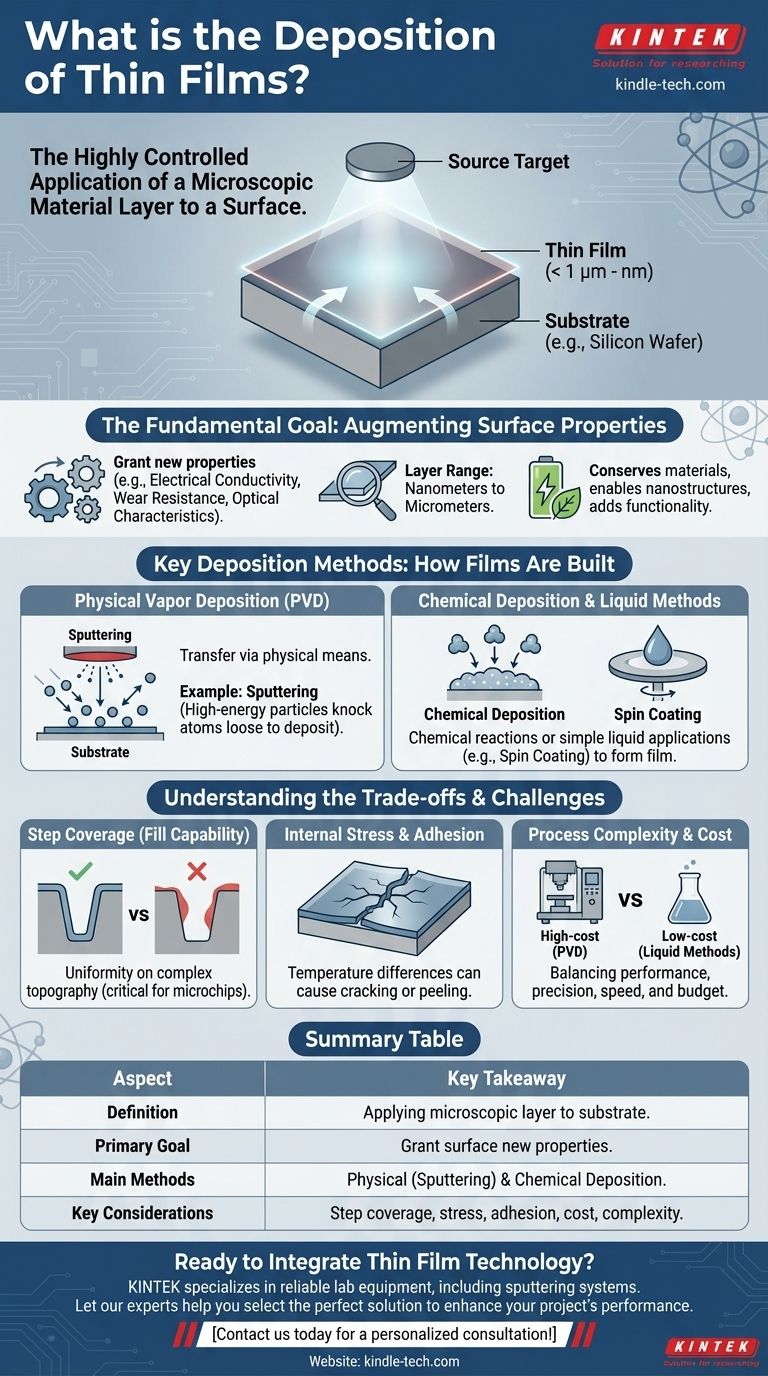

At its core, thin film deposition is the highly controlled process of applying a microscopic layer of one material onto the surface of another, known as a substrate. This synthesis allows us to grant an object's surface new properties—such as electrical conductivity, wear resistance, or specific optical characteristics—that the underlying bulk material does not possess on its own.

Thin film deposition isn't just about applying a coating; it's a foundational manufacturing process for virtually all modern technology. By precisely controlling the application of atomic-scale layers, we can engineer materials with novel properties, enabling everything from powerful microchips to efficient solar panels.

The Fundamental Goal: Augmenting a Material's Surface

What Constitutes a "Thin Film"?

A thin film is a layer of material ranging from fractions of a nanometer to several micrometers in thickness. These layers are so thin that their properties can differ significantly from those of the same material in bulk form.

The Substrate and the Target

The process involves two main components. The substrate is the base material or object being coated, such as a silicon wafer or a piece of glass. The target is the source material that will form the film itself.

Why Not Just Use a Solid Block of Material?

Deposition is used because it provides unique advantages. It conserves rare or expensive materials, allows for the creation of unique nanostructured coatings, and adds functionality with minimal volume and weight.

Key Deposition Methods: How Films Are Built

There are numerous techniques for depositing thin films, which generally fall into two major categories: physical and chemical.

Physical Vapor Deposition (PVD)

PVD techniques transfer material from a solid target to the substrate through physical means.

A common example is sputtering. Imagine a microscopic sandblaster, but instead of eroding a surface, you are using high-energy particles (ions) to bombard a target. This bombardment knocks atoms loose from the target, which then travel and deposit onto the substrate, forming a thin, uniform film.

Chemical Deposition

These methods use chemical reactions at the substrate's surface to form the film. The precursors are often gases or liquids that react or decompose, leaving the desired material behind.

Simpler Liquid-Based Methods

For some applications, simpler methods are sufficient. Techniques like spin coating or drop casting involve applying a liquid precursor and then evaporating the solvent to leave the thin film.

Understanding the Trade-offs

Choosing a deposition method involves balancing performance, cost, and the specific requirements of the final product. No single method is perfect for every application.

The Challenge of Step Coverage

Step coverage, or fill capability, describes how uniformly a film covers a substrate with complex surface topography, like the trenches in a microchip.

It is a critical parameter in semiconductor manufacturing. A process with poor step coverage may create thin, weak spots or gaps in the film, leading to device failure.

Internal Stress and Adhesion

The temperature of the substrate during deposition is a critical factor. Differences in the thermal expansion coefficients between the film and the substrate can create significant internal stress as the component cools.

High stress can cause the film to crack or peel away from the substrate, compromising the device. Managing this stress is key to creating durable and reliable coatings.

Process Complexity and Cost

High-precision methods like sputtering produce excellent, dense films but require expensive vacuum equipment and are relatively slow. Simpler methods like spin coating are fast and cheap but offer less control over the film's final properties.

Making the Right Choice for Your Goal

The best deposition technique depends entirely on your project's technical requirements, material constraints, and budget.

- If your primary focus is high-purity, dense films for complex electronics: You will likely need a Physical Vapor Deposition method like sputtering for its precise control over thickness and uniformity.

- If your primary focus is large-area coverage for applications like solar cells or displays: A combination of PVD and chemical methods is often used to balance performance and manufacturing throughput.

- If your primary focus is rapid prototyping or lab-scale research on a limited budget: Simpler liquid-based methods like spin coating or drop casting offer a viable and accessible starting point.

Understanding these fundamental principles empowers you to select and optimize the processes that turn raw materials into functional, high-performance devices.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Definition | Applying a microscopic layer (nanometers to micrometers) of material onto a substrate. |

| Primary Goal | To grant a surface new properties (e.g., conductivity, hardness) that the bulk material lacks. |

| Main Methods | Physical Vapor Deposition (PVD) like sputtering, and Chemical Deposition. |

| Key Considerations | Step coverage, internal stress, adhesion, process complexity, and cost. |

Ready to integrate thin film technology into your research or production?

The right deposition equipment is critical for achieving the desired film properties, whether for microchips, solar panels, or advanced coatings. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable sputtering systems and more.

Let our experts help you select the perfect solution to enhance your project's performance and efficiency. Contact us today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing