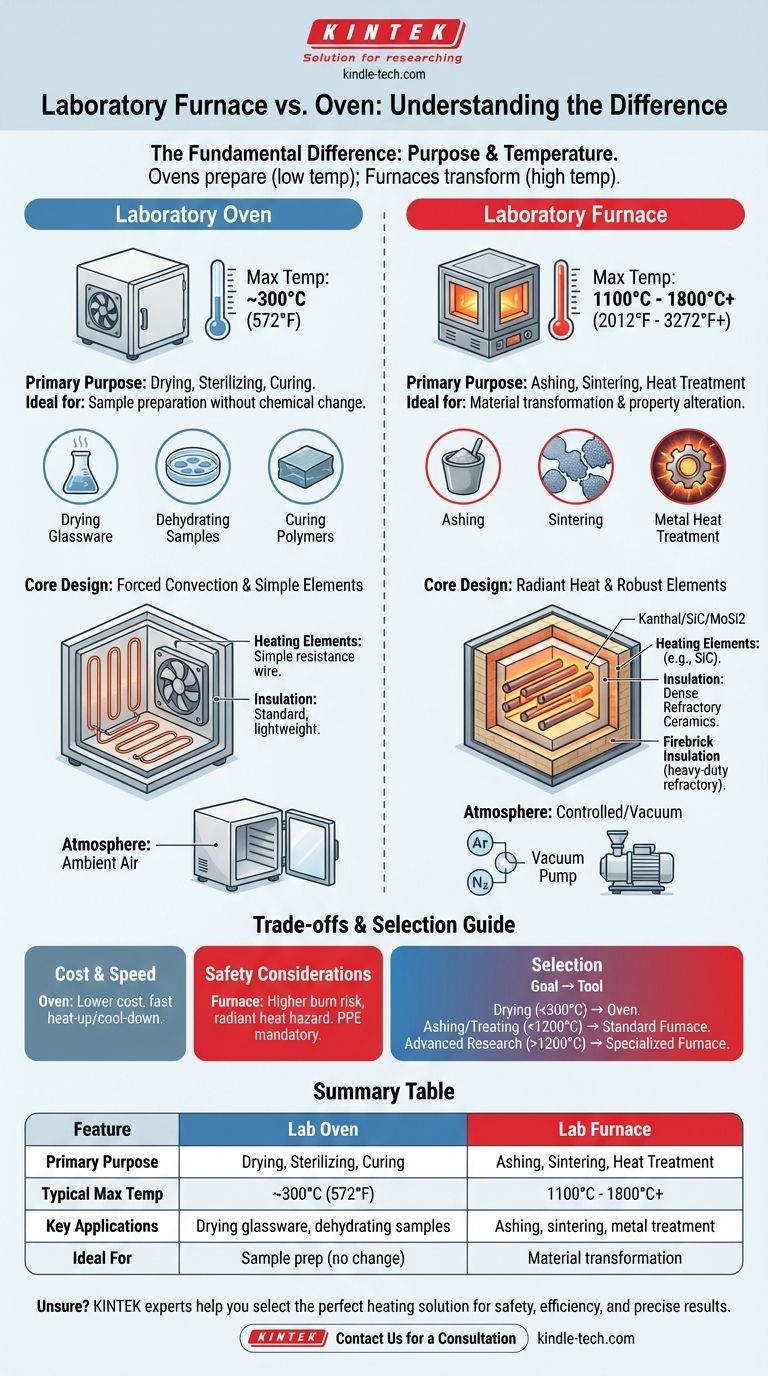

The fundamental difference between a laboratory furnace and an oven is their maximum achievable temperature and, consequently, their intended application. An oven is designed for lower-temperature tasks like drying, sterilizing, and curing, while a furnace generates the extreme heat required to fundamentally alter a material's properties, such as in metallurgy or ceramics.

While both are essentially insulated boxes that get hot, the distinction is not about degree, but about purpose. An oven uses heat to prepare a sample, whereas a furnace uses heat to transform it.

The Defining Factor: Temperature Range and Purpose

The operational temperature range is the most critical distinction. This difference in heat capability dictates the types of processes each instrument can perform.

Laboratory Ovens: Low-Temperature Precision

A laboratory oven typically operates at temperatures from just above ambient to around 300°C (572°F).

Their primary function is to remove moisture or cure materials at controlled, relatively low temperatures. Common applications include drying glassware, dehydrating samples for analysis, sterilizing equipment, or curing polymers and epoxies.

Most lab ovens use forced convection, where a fan circulates hot air to ensure uniform temperature distribution, which is critical for sensitive processes.

Laboratory Furnaces: High-Temperature Transformation

A laboratory furnace, often called a muffle furnace, is built for high-temperature work, frequently reaching 1100°C (2012°F) and with specialized models exceeding 1800°C (3272°F).

This intense heat is used for processes that change a material’s chemical or physical structure. Key applications include ashing (burning off organic matter), sintering (fusing ceramic powders), calcination (high-temperature decomposition), and the heat treatment of metals like annealing or hardening.

How They Work: Core Design Differences

The vast temperature gap between ovens and furnaces necessitates fundamentally different designs in their construction, heating elements, and insulation.

Heating Elements and Insulation

Ovens use simple resistance wire elements, which are sufficient for their temperature range. Furnaces require more robust heating elements made of materials like Kanthal (FeCrAl alloy), silicon carbide (SiC), or molybdenum disilicide (MoSi2) to withstand extreme temperatures.

Similarly, furnace insulation is far more substantial. It consists of dense refractory ceramics and firebrick designed to contain intense heat safely and efficiently, resulting in much thicker walls and greater thermal mass compared to a standard oven.

Construction and Materials

An oven is typically constructed from stainless steel and is relatively lightweight. A furnace is a heavy-duty piece of equipment with a robust, often powder-coated steel exterior and a dense ceramic interior chamber (the "muffle") that protects the heating elements from contamination.

Atmospheric Control

While most ovens operate in ambient air, many furnace applications require a controlled atmosphere to prevent oxidation at high temperatures. These furnaces may include ports for introducing inert gases like argon or nitrogen, or even be designed to operate under a vacuum.

Understanding the Trade-offs

Choosing between an oven and a furnace involves clear trade-offs in performance, cost, and safety.

Cost and Energy Consumption

Furnaces are significantly more expensive to purchase and operate than ovens. Their power consumption is substantially higher due to the energy required to reach and maintain extreme temperatures.

Heat-Up and Cool-Down Rates

An oven can heat up and cool down relatively quickly. A furnace, due to its massive thermal mass from the heavy insulation, heats up much more slowly and can take many hours, or even days, to cool back to room temperature safely.

Safety Considerations

Both instruments pose burn risks, but the hazards associated with a furnace are more severe. The extreme temperatures present a significant radiant heat hazard, and mishandling materials at over 1000°C can be catastrophic. Proper personal protective equipment (PPE), including heat-resistant gloves and face shields, is non-negotiable.

Selecting the Right Equipment for Your Application

Use your end goal to determine the correct instrument for your process.

- If your primary focus is drying, curing, or sterilizing below 300°C: A laboratory oven offers the necessary precision and efficiency.

- If your primary focus is ashing organic material or performing basic metal heat treating up to 1200°C: A standard muffle furnace is the correct choice.

- If your primary focus is advanced materials research with ceramics or exotic alloys above 1200°C: You will require a specialized high-temperature furnace with appropriate heating elements and atmospheric controls.

Understanding the purpose behind the heat is the key to selecting the right tool for your scientific work.

Summary Table:

| Feature | Laboratory Oven | Laboratory Furnace |

|---|---|---|

| Primary Purpose | Drying, Sterilizing, Curing | Ashing, Sintering, Heat Treatment |

| Typical Max Temp | ~300°C (572°F) | 1100°C to 1800°C+ (2012°F to 3272°F+) |

| Key Applications | Drying glassware, dehydrating samples, curing polymers | Ashing, sintering powders, calcination, metal treatment |

| Ideal For | Sample preparation without chemical change | Material transformation and property alteration |

Unsure whether your lab needs an oven or a furnace? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect heating solution for your specific application, ensuring safety, efficiency, and precise results. Contact us today for a personalized consultation and discover the KINTEK difference!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a platform shaker play in biological toxicity assessment? Standardize Your Mine Water Testing Protocols

- What are the different types of catalysts used in pyrolysis? A Guide to Optimizing Biomass Conversion

- What is the energy efficiency of pyrolysis? It's a System, Not a Single Number

- Which of the following measurement technique commonly used to find the thickness of thin films? A Guide to Choosing the Right Method

- What is the temperature range for annealing? Master Material-Specific Heat Treatment

- What is the difference between RF and DC power? Choosing the Right Power for Your Application

- What is the HIP process in powder metallurgy? Achieve Full Density & Superior Material Properties

- What materials are needed for a FTIR? Essential Guide to Sample Prep and Optics