The fundamental difference lies in how they generate and deliver force. A mechanical press uses a motor-driven flywheel to store kinetic energy, which is then transferred through a crank mechanism to create a powerful stamping motion in a fixed stroke. In contrast, a hydraulic press uses a pump to pressurize fluid, applying a constant, controlled force throughout its entire, variable stroke.

The choice between a mechanical and a hydraulic press is a classic engineering trade-off. Mechanical presses are built for speed and repeatability in high-volume applications, while hydraulic presses offer superior force control and flexibility.

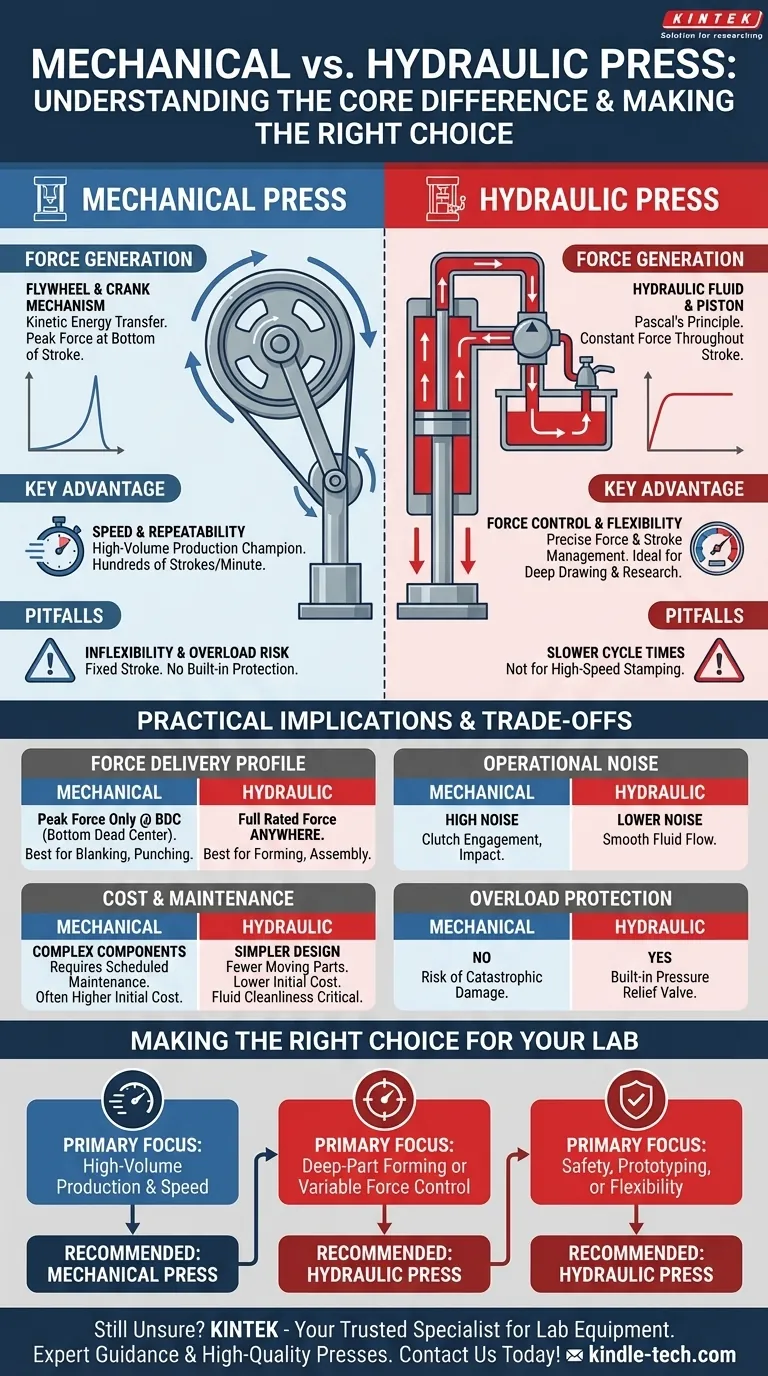

How They Generate Force: The Core Difference

The mechanism used to generate force dictates the entire operational character of the press, from its speed and control to its maintenance profile.

Mechanical Press: The Flywheel and Crank

A mechanical press functions much like an engine in reverse. An electric motor spins a heavy flywheel, storing a large amount of kinetic energy.

When activated, a clutch engages and connects the spinning flywheel to a crank or eccentric gear. This converts the rotational energy into the powerful, reciprocating (up-and-down) motion of the press ram.

The force is not constant; it builds to its maximum capacity at the very bottom of the stroke, a point known as Bottom Dead Center (BDC).

Hydraulic Press: Pascal's Principle in Action

A hydraulic press operates on a basic principle of fluid dynamics. A pump moves hydraulic fluid (typically oil) into a cylinder, pushing against a piston.

According to Pascal's Principle, pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel. This allows a small force applied by the pump to be multiplied into a massive force by the piston.

This method allows the press to generate its full, rated tonnage at any point in the stroke, from the very top to the very bottom.

Control vs. Speed: The Primary Trade-off

Your application's need for either high-speed output or precise force control will almost always determine which press is the correct choice.

The Advantage of Speed: Mechanical Presses

Mechanical presses are champions of high-volume production. Their fixed stroke cycle is incredibly fast and highly repeatable, making them the standard for applications like blanking, punching, and shallow forming in industries like automotive manufacturing.

Once the flywheel is at speed, each cycle is an efficient transfer of stored energy, allowing for hundreds or even thousands of strokes per minute in some designs.

The Advantage of Control: Hydraulic Presses

Hydraulic presses offer complete control. The operator can precisely manage the force, stroke distance, ram speed, and duration of pressure application.

This is invaluable for tasks like deep drawing, where a constant force is needed throughout a long stroke, or for assembly operations that require a specific, sustained pressure. This control also extends to research and lab environments where precision is paramount.

Understanding the Practical Implications

Beyond speed and control, the design of each press has significant consequences for day-to-day operation.

Force Delivery Profile

As mentioned, a mechanical press delivers its peak force only at the bottom of its stroke. This is perfect for "punching" operations like coining and blanking.

A hydraulic press can deliver its full rated force anywhere in the stroke. This makes it ideal for forming operations where the material needs to be pushed and shaped over a longer distance.

Operational Noise

Hydraulic presses are significantly quieter. Their operation involves the smooth flow of fluid and fewer high-impact moving parts.

In contrast, the clutch engagement and stamping impact of a mechanical press generate considerable noise.

Cost and Maintenance

Hydraulic presses often have a lower initial purchase cost. Their design is simpler with fewer moving parts, which can also lead to easier maintenance and fewer breakdowns.

While hydraulic maintenance is straightforward, it requires attention to fluid cleanliness and the potential for leaks. Mechanical presses have more complex components (clutch, brake, bearings) that require regular scheduled maintenance.

Understanding the Trade-offs

Neither press is universally superior. Understanding their inherent limitations is crucial for making an informed decision.

Mechanical Press Pitfalls: Inflexibility and Overload

The primary drawback of a mechanical press is its fixed stroke. You cannot easily change the stroke length.

Furthermore, if a workpiece or die is set up incorrectly (e.g., too thick), the press will attempt to complete its stroke regardless, which can cause catastrophic damage to the press frame or the tooling. They have no built-in overload protection.

Hydraulic Press Pitfalls: Slower Cycle Times

For high-speed, repetitive stamping, a hydraulic press is simply too slow. The time it takes for the hydraulic system to cycle and build pressure cannot match the speed of a flywheel.

Built-in Safety: Hydraulic Overload Protection

A major advantage of hydraulic presses is their inherent overload protection. A pressure relief valve ensures the system will never exceed the set tonnage. If the force required is greater than the setting, the press simply stops, preventing damage to the machine and dies.

Making the Right Choice for Your Application

Selecting the correct press comes down to analyzing the primary goal of your specific forming or stamping operation.

- If your primary focus is high-volume production and speed: A mechanical press is the industry standard for its rapid, repeatable cycles.

- If your primary focus is deep-part forming or variable force control: A hydraulic press offers the unmatched flexibility and consistent pressure needed for these tasks.

- If your primary focus is safety, prototyping, or operational flexibility: A hydraulic press provides significant advantages with its tonnage control and built-in overload protection.

Ultimately, understanding this fundamental difference between speed-centric mechanical systems and control-centric hydraulic systems empowers you to select the right tool for your specific job.

Summary Table:

| Feature | Mechanical Press | Hydraulic Press |

|---|---|---|

| Force Generation | Flywheel & crank mechanism | Hydraulic fluid & piston (Pascal's Principle) |

| Speed | High (hundreds of strokes/minute) | Slower |

| Force Control | Peak force only at bottom of stroke | Full, constant force throughout the stroke |

| Best For | High-volume stamping, blanking, punching | Deep drawing, forming, applications requiring precise control |

| Overload Protection | No (risk of machine damage) | Yes (built-in pressure relief valve) |

| Noise Level | High | Lower |

Still Unsure Which Press is Right for Your Lab?

Choosing the correct press is critical for the efficiency and success of your operations. KINTEK, a trusted specialist in lab equipment and consumables, is here to help.

We provide expert guidance and high-quality presses tailored to your specific laboratory needs, whether you require the high-speed repetition of a mechanical press or the precise control of a hydraulic system.

Contact us today via our contact form to discuss your application and discover how the right press can enhance your lab's productivity and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Lab Heat Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System