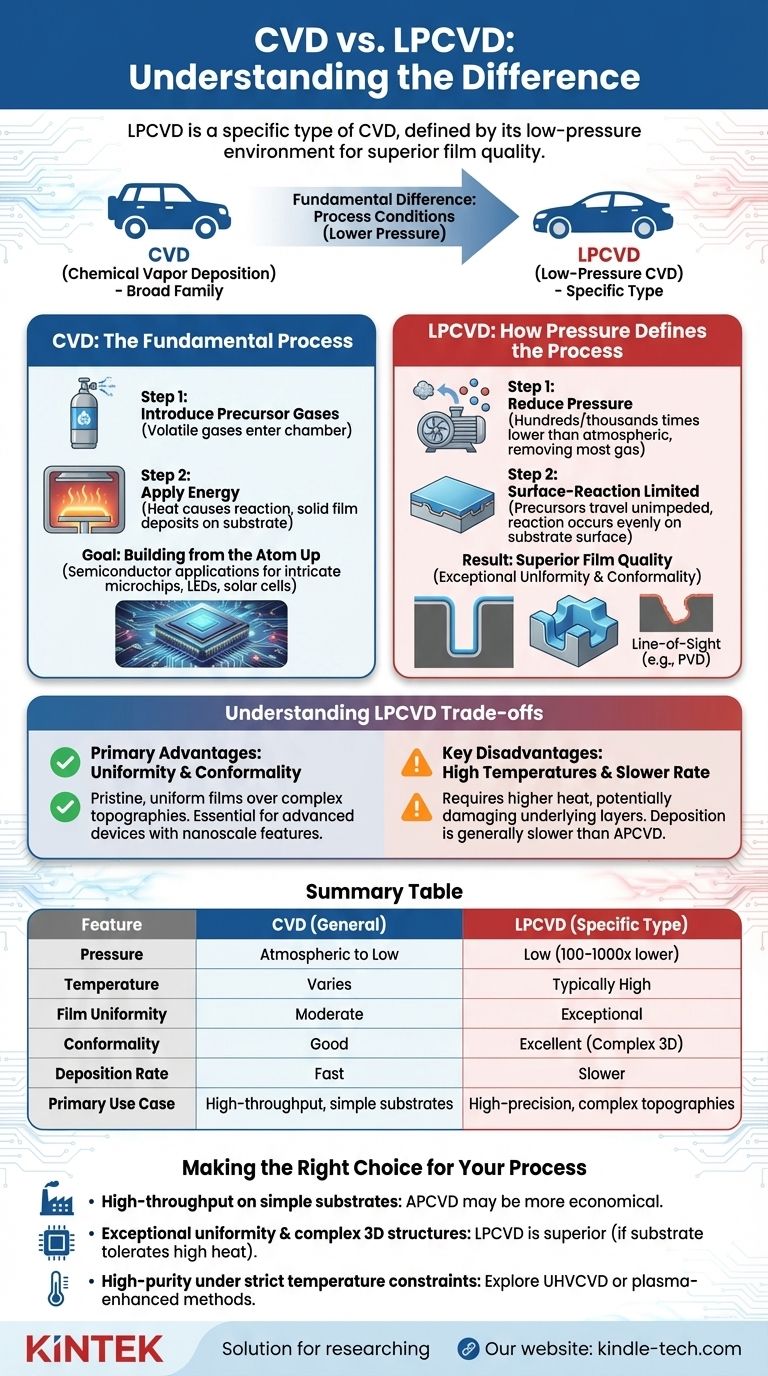

In short, LPCVD is a specific type of CVD. Chemical Vapor Deposition (CVD) is the broad name for a family of techniques used to create thin solid films from gaseous precursors. Low-Pressure Chemical Vapor Deposition (LPCVD) is one of these techniques, defined by its use of a low-pressure environment to achieve superior film quality. Think of CVD as "automobiles" and LPCVD as a specific model, like a "sedan."

The fundamental difference isn't the chemistry, but the process conditions. LPCVD intentionally lowers the chamber pressure to force the chemical reaction to occur primarily on the substrate surface, not in the gas above it. This yields highly uniform and conformal films, which is the primary reason for its use.

What is Chemical Vapor Deposition (CVD)?

The Fundamental Process

At its core, any CVD process involves two major steps. First, one or more volatile precursor gases are introduced into a reaction chamber containing the object to be coated, known as the substrate.

Second, energy—typically heat—is applied. This causes the gases to react or decompose, depositing a solid thin film onto the substrate surface.

The Goal: Building from the Atom Up

CVD is a cornerstone of modern manufacturing, especially in the semiconductor industry. It is used to build up the intricate, layered structures that form microchips, LEDs, and solar cells.

The technique is valued for its ability to produce highly pure and durable films with well-controlled properties.

How Pressure Defines the Process: Introducing LPCVD

The Problem with Atmospheric Pressure

When CVD is performed at normal atmospheric pressure (a process called APCVD), the reaction chamber is dense with gas molecules. This density leads to many collisions between molecules in the gas phase itself.

These gas-phase reactions are often undesirable. They can form tiny particles that fall onto the substrate, creating defects. This also depletes the precursor gas before it reaches the surface, leading to a non-uniform film thickness across the substrate.

The LPCVD Solution: Reducing Pressure

LPCVD operates at pressures hundreds or thousands of times lower than atmospheric pressure. By removing most of the gas molecules from the chamber, the chance of unwanted reactions in the gas phase plummets.

This forces the deposition to become a surface-reaction limited process. The precursor gases travel unimpeded to the substrate, where all the critical chemical reactions happen right on the surface.

The Result: Superior Film Quality

This surface-focused reaction is the key to LPCVD's advantages. Because the reaction happens evenly across every exposed surface, the resulting film is exceptionally uniform in thickness.

Furthermore, it provides outstanding conformality, meaning it can perfectly coat deep trenches, holes, and other complex 3D shapes without sealing them off. This is a critical advantage over line-of-sight deposition methods like PVD.

Understanding the Trade-offs of LPCVD

The Primary Advantage: Uniformity and Conformality

The main reason engineers choose LPCVD is for its ability to deposit pristine, uniform films over complex topographies. For creating advanced microelectronic devices with nanoscale features, this level of control is non-negotiable.

The Key Disadvantage: High Temperatures

To drive the chemical reaction efficiently on the surface without the help of high pressure, LPCVD typically requires higher process temperatures compared to other CVD methods.

This high heat can be a significant limitation. It can damage or alter underlying layers or devices that have already been fabricated on the substrate, forcing engineers to seek alternative, lower-temperature deposition methods.

Deposition Rate

While CVD processes can be very economical with high deposition rates, LPCVD is generally slower than its atmospheric pressure (APCVD) counterpart. The lower concentration of reactant gases means the film builds up more slowly. This is a direct trade-off: sacrificing speed for quality and uniformity.

Making the Right Choice for Your Process

Choosing a deposition method is a classic engineering decision that requires balancing the ideal film properties against the physical limitations of the process and substrate.

- If your primary focus is high-throughput production on simple, flat substrates: An atmospheric pressure process (APCVD) may be more economical due to its higher deposition rate.

- If your primary focus is exceptional uniformity and coating complex 3D structures: LPCVD is the superior choice, as long as your substrate and underlying materials can tolerate the high process temperatures.

- If your primary focus is depositing a high-purity film under strict temperature constraints: You would need to explore other techniques, such as Ultra-High Vacuum CVD (UHVCVD) or plasma-enhanced methods.

Ultimately, understanding the role of pressure is key to selecting the right tool for the job.

Summary Table:

| Feature | CVD (General) | LPCVD (Specific Type) |

|---|---|---|

| Pressure | Atmospheric to Low | Low (100-1000x lower than atmospheric) |

| Temperature | Varies | Typically High |

| Film Uniformity | Moderate | Exceptional |

| Conformality | Good | Excellent (coats complex 3D structures) |

| Deposition Rate | Fast | Slower |

| Primary Use Case | High-throughput, simple substrates | High-precision, complex topographies |

Need expert guidance on selecting the right deposition method for your lab?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for semiconductor and thin-film research. Whether you're working with CVD, LPCVD, or other advanced techniques, our solutions ensure precision, reliability, and optimal performance. Let us help you achieve superior film quality and efficiency in your processes.

Contact us today to discuss your specific needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth