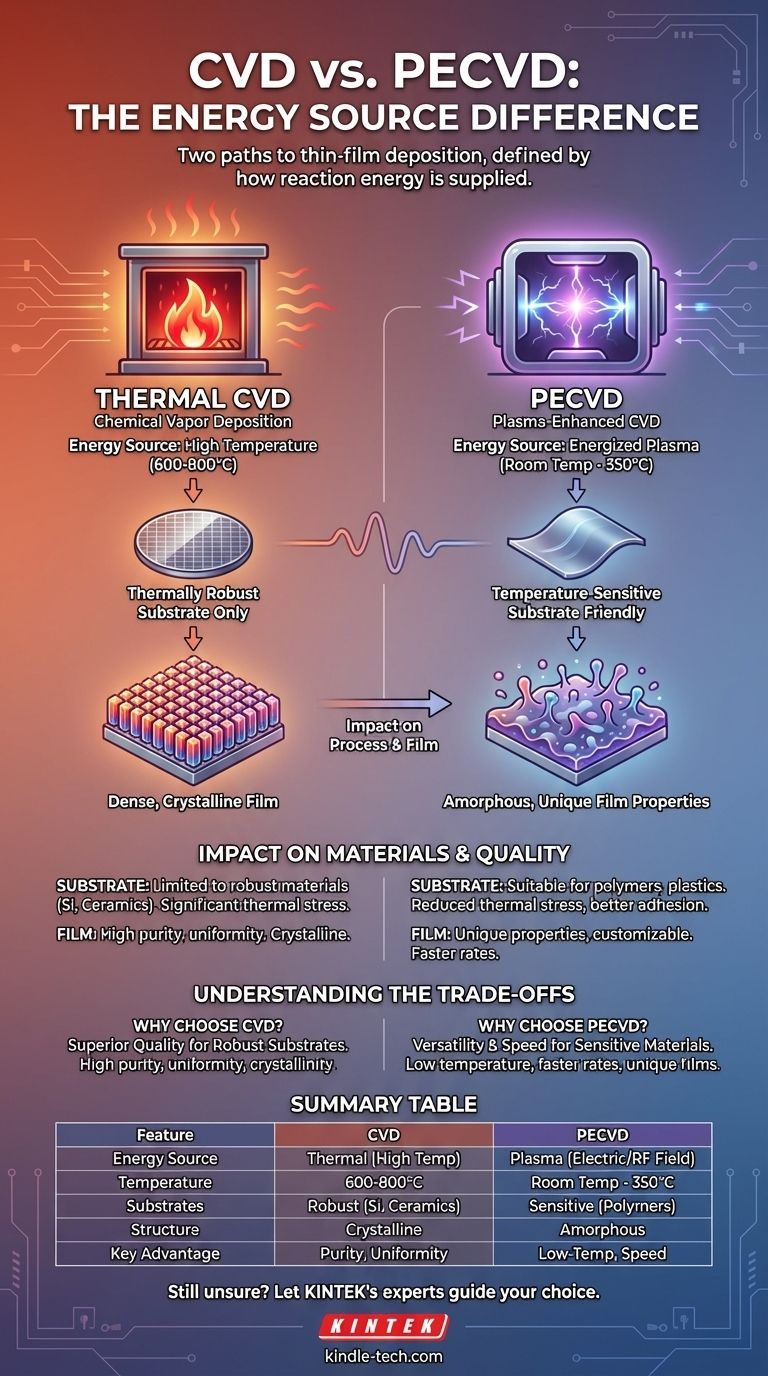

The fundamental difference between Chemical Vapor Deposition (CVD) and Plasma-Enhanced Chemical Vapor Deposition (PECVD) is the source of energy used to drive the film-forming reaction. Conventional CVD uses high temperatures (typically 600-800°C) to thermally decompose gas molecules. In contrast, PECVD uses an energized plasma to break down the gas molecules, allowing the process to occur at much lower temperatures (room temperature to 350°C).

Choosing between CVD and PECVD is not about which is universally "better," but which is appropriate for your specific substrate and desired film properties. The core distinction lies in using thermal energy versus plasma energy, a choice that dictates everything from material compatibility to the final film structure.

How Energy Dictates the Process

The method of supplying energy is the central factor that differentiates these two powerful thin-film deposition techniques. This choice has significant downstream consequences for the process and its outcome.

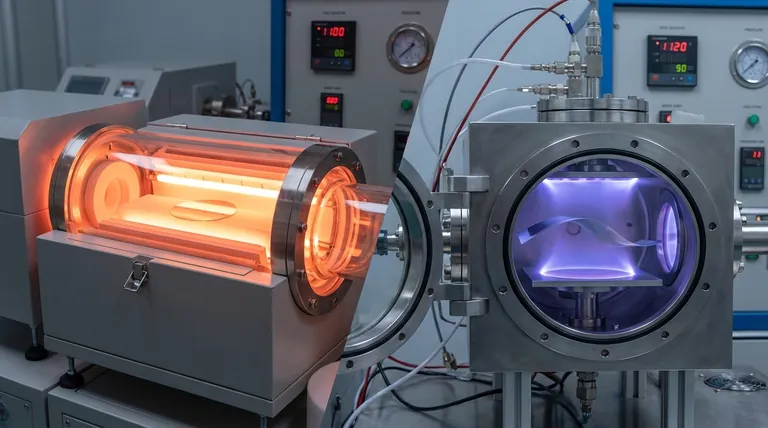

Thermal CVD: The High-Temperature "Oven"

In a conventional CVD process, precursor gases are introduced into a chamber where the substrate is heated to very high temperatures. This thermal energy acts like an oven, providing the activation energy needed to break chemical bonds and initiate a reaction on the substrate's surface, depositing a solid film.

This reliance on heat means the substrate itself must be able to withstand extreme temperatures without degrading, melting, or warping.

PECVD: The Low-Temperature Plasma "Catalyst"

PECVD replaces intense heat with plasma. By applying a strong electric or radio frequency (RF) field to the gas, it becomes ionized, creating a plasma filled with high-energy electrons.

These electrons collide with the precursor gas molecules, transferring their energy and breaking chemical bonds. This allows the deposition reaction to proceed without requiring the substrate to be hot, effectively bypassing the high-temperature requirement of conventional CVD.

The Impact on Materials and Film Quality

The difference between a thermal and a plasma-driven process directly impacts material selection, film structure, and mechanical properties.

Substrate Compatibility

This is the most critical implication. The low-temperature nature of PECVD makes it suitable for depositing films on temperature-sensitive materials, such as plastics, polymers, and other organic substrates that would be destroyed by a CVD process.

Conventional CVD is therefore limited to thermally robust substrates like silicon wafers, ceramics, and certain metals.

Film Structure and Properties

Because PECVD's plasma breaks bonds non-selectively using high-energy electrons, it can create unique, non-equilibrium films. This often results in amorphous (non-crystalline) structures with distinct properties that are not achievable with thermal methods.

Thermal CVD, which relies on more controlled, heat-driven equilibrium kinetics, typically produces more stable, dense, and often polycrystalline or crystalline films.

Stress and Adhesion

The high temperatures of CVD can induce significant thermal stress in the film and substrate as they cool, potentially leading to cracking or delamination.

PECVD's low-temperature process dramatically reduces this thermal stress, which can lead to stronger film adhesion and greater mechanical stability, especially on materials with different thermal expansion coefficients.

Understanding the Trade-offs

Neither method is a perfect solution for all scenarios. The choice involves balancing the advantages and disadvantages of each.

Why Choose CVD?

Conventional CVD is often preferred when the substrate can tolerate the heat. The slow, thermally-driven process can result in films with extremely high purity and uniformity. For many applications in semiconductor manufacturing, the quality and crystallinity of a thermally deposited film are superior.

The Advantages of PECVD

PECVD offers significant operational benefits. It enables faster deposition rates and is often more cost-effective. Its ability to create unique film properties (like hydrophobic surfaces or UV protection) by simply changing the gas formulation makes it highly versatile and customizable.

Potential Downsides

The plasma environment in PECVD can sometimes lead to the incorporation of other elements (like hydrogen from precursor gases) into the film, which can be an undesirable impurity for certain high-performance electronic applications. The equipment is also generally more complex due to the need for RF power supplies and plasma containment.

Making the Right Choice for Your Application

Your decision depends entirely on your substrate material, budget, and the desired properties of your final film.

- If your primary focus is coating heat-sensitive materials (like polymers): PECVD is the only viable option due to its low-temperature process.

- If your primary focus is achieving the highest purity and crystalline quality on a robust substrate (like a silicon wafer): Conventional CVD is often the superior choice for its high-quality, dense films.

- If your primary focus is rapid deposition, lower cost, or creating unique amorphous films: PECVD provides significant advantages in speed, efficiency, and material versatility.

Understanding this core difference in energy source empowers you to select the precise tool for your specific engineering goal.

Summary Table:

| Feature | CVD (Chemical Vapor Deposition) | PECVD (Plasma-Enhanced CVD) |

|---|---|---|

| Energy Source | Thermal (High Temperature) | Plasma (Electric/RF Field) |

| Typical Temperature | 600-800°C | Room Temp - 350°C |

| Substrate Compatibility | Thermally robust (e.g., silicon, ceramics) | Temperature-sensitive (e.g., polymers, plastics) |

| Typical Film Structure | Dense, Crystalline/Polycrystalline | Amorphous, Unique non-equilibrium properties |

| Key Advantage | High purity, uniformity, crystalline quality | Low-temperature processing, speed, versatility |

Still unsure which deposition method is right for your project?

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and R&D teams. Our experts can help you navigate the choice between CVD and PECVD to ensure you achieve the optimal film properties for your specific substrate and application.

Contact our technical team today to discuss your requirements and discover how our solutions can enhance your research and development process.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How strong is DLC coating? Discover the Ultimate Shield for Wear and Friction

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What role does in-situ Argon (Ar) plasma pretreatment play in PECVD? Achieve Superior Adhesion for Aluminum Alloys

- What is the difference between LPCVD and PECVD oxide? Choosing the Right Deposition Method for Your Thermal Budget

- What is the effect of temperature on PECVD? Optimize Film Quality vs. Substrate Safety

- What precursor gases are used to form silicon dioxide and silicon nitride films via PECVD? Expert Precursor Guide

- Why use a PECVD system for Si-DLC coatings? Enhance Substrate Performance with Low-Temperature Precision

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films