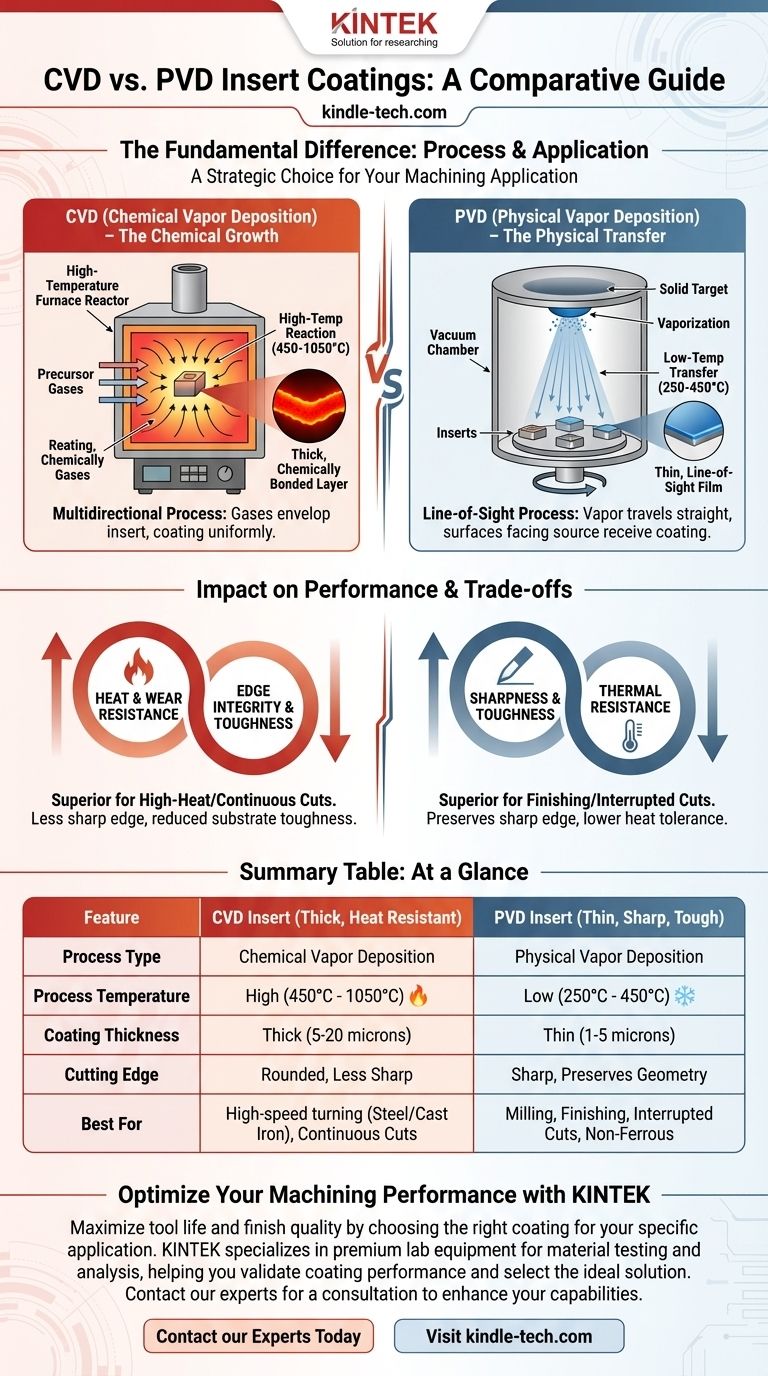

The fundamental difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) coatings on an insert lies in how the coating is applied. CVD uses a high-temperature chemical reaction between precursor gases and the insert's surface to "grow" a thick, highly adherent layer. In contrast, PVD uses a lower-temperature physical process, where a solid coating material is vaporized in a vacuum and deposited directly onto the insert in a line-of-sight transfer.

Choosing between a CVD and PVD insert is not a matter of which technology is superior, but a strategic decision based on your specific machining application. The choice is a direct trade-off between the superior heat and wear resistance of CVD and the superior edge sharpness and toughness of PVD.

The Core Process: Chemical vs. Physical

The names "Chemical Vapor Deposition" and "Physical Vapor Deposition" directly describe their fundamental difference. This distinction in process is the root cause of every performance variation between the two coatings.

How CVD Works: A Chemical Reaction

CVD is a high-temperature process, typically occurring between 450°C and 1050°C.

In a CVD reactor, the carbide inserts are exposed to a precise mixture of gases. These gases react with each other and with the hot surface of the insert, forming a new, solid coating material that chemically bonds to the substrate.

Think of it like baking a cake. You introduce ingredients (gases) that react under heat to form something entirely new (the coating) that is chemically integrated with the pan (the insert). This process is multidirectional, meaning the gases envelop the insert and coat all surfaces uniformly.

How PVD Works: A Physical Transfer

PVD is a comparatively low-temperature process, operating between 250°C and 450°C.

Inside a vacuum chamber, a solid target made of the desired coating material (like Titanium Nitride) is vaporized by physical means, such as bombardment with ions. This vaporized material then travels in a straight line and condenses on the cooler inserts, forming a thin film.

This is analogous to spray painting. The source material is physically transferred from one place to another without a chemical change. This process is line-of-sight, meaning surfaces facing away from the vapor source receive less coating.

How Process Differences Impact Insert Performance

The temperature, method of application, and bonding mechanism of CVD and PVD create distinct advantages and disadvantages for machining.

Temperature and Its Consequences

The high heat of the CVD process is its greatest strength and a significant limitation. It creates an exceptionally strong chemical bond, leading to fantastic adhesion and wear resistance.

However, these high temperatures can negatively affect the underlying carbide substrate, reducing its toughness and making the cutting edge more susceptible to cracking in high-impact applications like milling.

PVD's lower temperature has no negative impact on the carbide substrate's toughness, making PVD-coated inserts ideal for interrupted cuts.

Coating Thickness and Adhesion

CVD coatings are thick (typically 5-20 microns). This thickness provides a robust thermal barrier and excellent wear resistance, perfect for continuous, high-heat cutting operations.

PVD coatings are thin (typically 1-5 microns). This thinness, combined with the low-temperature process, perfectly preserves the sharp, molded geometry of the cutting edge.

Surface Finish and Geometry

PVD coatings are exceptionally smooth. This smoothness reduces friction and helps prevent built-up edge (BUE), which is critical when machining gummy materials like aluminum and stainless steel.

CVD coatings can be inherently rougher and tend to round the cutting edge due to their thickness. This makes them less suitable for fine finishing passes or when a razor-sharp edge is required.

Understanding the Trade-offs

Neither coating is universally better; they represent two different sets of compromises tailored for different tasks.

The CVD Trade-off: Heat Resistance vs. Edge Integrity

You gain unparalleled thermal stability and crater wear resistance with a CVD coating. This makes it the champion of high-speed turning in steels and cast irons.

The price for this is a less sharp edge and potentially reduced toughness of the insert itself, making it less ideal for tasks requiring high precision or involving heavy impacts.

The PVD Trade-off: Sharpness vs. Thermal Limits

You gain a perfectly sharp, smooth, and tough cutting edge with a PVD coating. This makes it ideal for finishing, milling, and machining sticky materials where a clean cut is paramount.

The price is lower thermal resistance compared to CVD. At the very high temperatures seen in aggressive roughing, a PVD coating can break down faster.

Making the Right Choice for Your Application

Selecting the right coating is about matching its inherent properties to the demands of your specific operation.

- If your primary focus is high-speed roughing of steel or cast iron: Choose CVD. Its thick thermal barrier provides the wear resistance needed for continuous, high-heat cuts.

- If your primary focus is milling or interrupted cuts: Choose PVD. Its lower-temperature application preserves the substrate's toughness, which is essential for resisting chipping and thermal cracking from impacts.

- If your primary focus is finishing or machining non-ferrous/gummy materials (aluminum, stainless steel): Choose PVD. The sharp, smooth coating reduces friction and built-up edge, resulting in a superior surface finish.

- If your primary focus is general-purpose turning: A modern, multi-layer CVD grade often provides the best balance of wear resistance and toughness for a wide range of steel applications.

By understanding these core principles, you can select an insert coating not just by its name, but by its fundamental suitability for the task at hand.

Summary Table:

| Feature | CVD Insert | PVD Insert |

|---|---|---|

| Process Type | Chemical Vapor Deposition | Physical Vapor Deposition |

| Process Temperature | High (450°C - 1050°C) | Low (250°C - 450°C) |

| Coating Thickness | Thick (5-20 microns) | Thin (1-5 microns) |

| Cutting Edge | Rounded, less sharp | Sharp, preserves geometry |

| Best For | High-speed, continuous turning | Milling, finishing, interrupted cuts |

Optimize Your Machining Performance with KINTEK

Choosing between CVD and PVD coatings is critical for maximizing tool life, productivity, and finish quality. The right choice depends entirely on your specific application, material, and machining operation.

KINTEK specializes in premium lab equipment and consumables for material testing and analysis, serving the precise needs of laboratories and R&D departments. Our expertise can help you validate coating performance and select the ideal solution for your requirements.

Let us help you make the right choice. Contact our experts today for a consultation to discuss how our solutions can enhance your laboratory's capabilities and support your material development projects.

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Optical Windows for Lab Applications

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What is a substitute for tungsten carbide? Explore Advanced Materials for Superior Performance

- What precautions should be taken when cutting carbon cloth? Avoid Short Circuits and Ensure Device Safety

- What are the advantages of diamond cutting tool material? Achieve Superior Precision and Productivity

- What are the disadvantages of screw extrusion? High Costs and Complexity Explained

- Can sintered metal be machined? Master the Techniques for Porous Materials