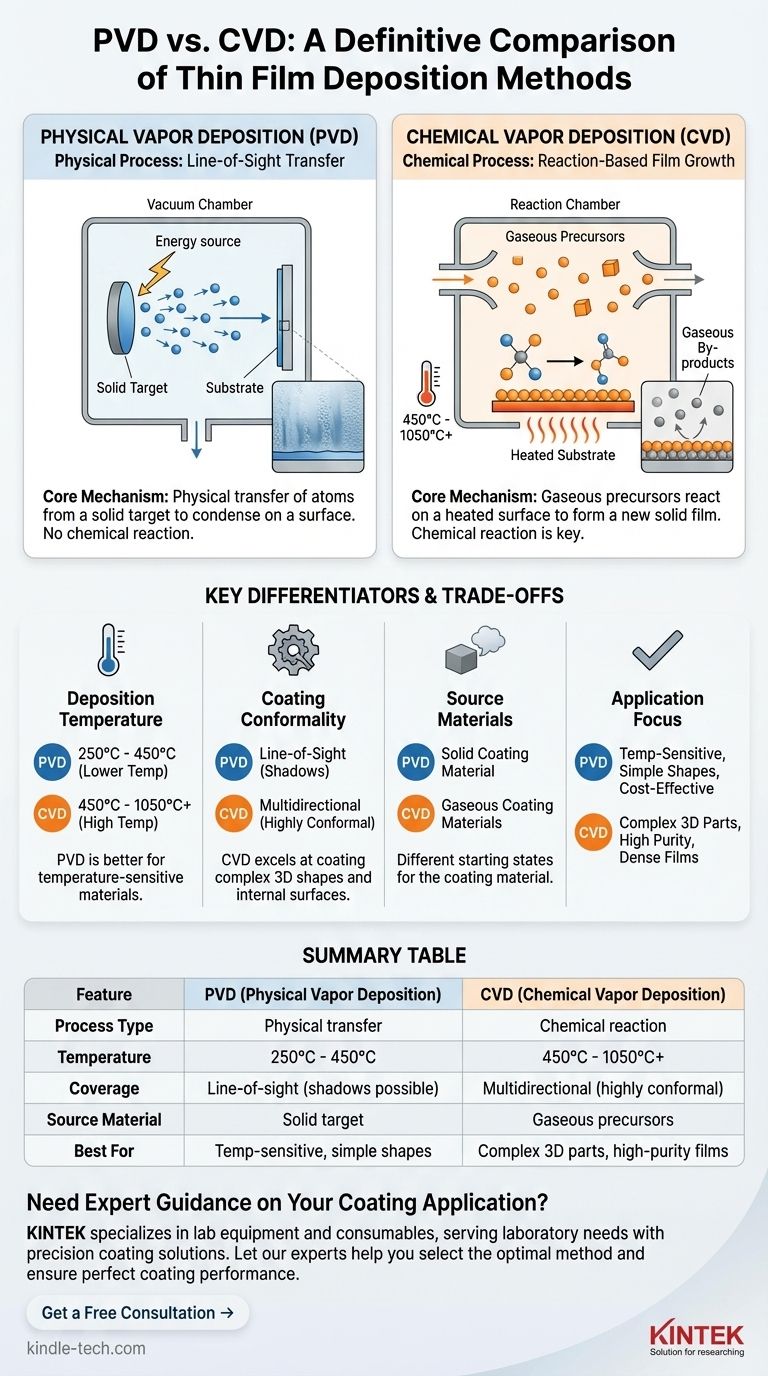

At its core, the difference is simple: Physical Vapor Deposition (PVD) is a physical process, where a solid material is vaporized and condenses onto a substrate, much like water vapor frosting a cold window. In contrast, Chemical Vapor Deposition (CVD) is a chemical process, where precursor gases react on a heated substrate surface to form an entirely new solid film, leaving by-products behind.

The essential distinction is how the film is created. PVD is a line-of-sight physical transfer of material from a source to a surface. CVD is a chemical reaction that builds the film from gaseous ingredients directly on the surface itself.

The Core Mechanism: Physical vs. Chemical

To truly understand which method to use, you must first grasp their fundamental operating principles. The names themselves provide the clearest clue: one is purely physical, the other is driven by chemistry.

Physical Vapor Deposition (PVD): A Line-of-Sight Process

PVD is best thought of as a mechanical or physical transfer. A solid source material, known as a "target," is bombarded with energy inside a vacuum chamber.

This energy physically knocks atoms or molecules loose from the target, turning them into a vapor. This vapor then travels in a straight line—a "line-of-sight"—until it strikes the substrate and condenses to form the coating.

The key here is that no chemical reaction occurs. The deposited film is composed of the same material that left the source target.

Chemical Vapor Deposition (CVD): A Reaction-Based Process

CVD is fundamentally different. It doesn't start with a solid source material that is simply moved. Instead, it introduces specific gases, called precursors, into a reaction chamber.

The substrate inside the chamber is heated to a high temperature. When the precursor gases come into contact with the hot surface, they undergo a chemical reaction.

This reaction breaks the gases down and forms a new, solid film on the substrate. Unwanted gaseous by-products from this reaction are then pumped out of the chamber.

Key Differentiators in Practice

The difference in mechanism leads to significant practical differences in temperature, how well the coating covers a surface, and the materials involved.

Deposition Temperature

This is one of the most critical distinguishing factors.

PVD is a lower-temperature process, typically operating between 250°C and 450°C.

CVD is a high-temperature process, requiring anywhere from 450°C to over 1050°C to drive the necessary chemical reactions.

Coating Conformality

Conformality refers to the coating's ability to uniformly cover a complex, three-dimensional surface.

PVD is a line-of-sight process. This means it excels at coating flat surfaces but struggles with complex geometries, as any recessed areas or undercuts will be left uncoated in a "shadow."

CVD is a multidirectional process. Because the precursor gases flow all around the substrate, the chemical reaction can occur on every exposed surface, resulting in a highly uniform and conformal coating even on intricate shapes.

Source Materials

The state of the starting material is another clear distinction.

PVD processes begin with a solid coating material (the target) that is physically vaporized.

CVD processes begin with gaseous coating materials (the precursors) that are chemically transformed.

Understanding the Trade-offs

Neither process is universally superior; the choice is always dictated by the application and its constraints. Understanding the limitations of each is key to making an informed decision.

The Temperature Limitation of CVD

The high temperatures required for CVD are its primary drawback. They make it unsuitable for coating materials with low melting points or those that could be damaged by thermal stress, such as plastics, certain aluminum alloys, or tempered steels.

The Line-of-Sight Limitation of PVD

The primary weakness of PVD is its inability to uniformly coat complex shapes. For parts with internal channels, threads, or sharp corners, achieving a consistent coating thickness with PVD is extremely difficult, if not impossible.

Process Complexity and By-products

While conceptually straightforward, CVD involves handling volatile and sometimes toxic precursor gases. The process also creates chemical by-products that must be safely managed and exhausted, adding a layer of complexity compared to the more direct physical process of PVD.

Making the Right Choice for Your Application

Your final decision should be based on your substrate material and the desired outcome for your coating.

- If your primary focus is coating a temperature-sensitive material: PVD is the clear choice due to its significantly lower operating temperatures.

- If your primary focus is achieving a perfectly uniform coating on a complex 3D part: CVD's ability to coat all surfaces via gas-phase reaction is superior.

- If your primary focus is achieving extremely high purity and dense films: CVD often has an edge, as the chemical reaction process can yield highly ordered, non-porous coatings.

- If your primary focus is a mechanically simpler process for a hard, wear-resistant coating on a flat or simple surface: PVD is often the more direct and cost-effective solution.

Ultimately, choosing between these two powerful techniques depends entirely on matching the process to the specific demands of your material and your goal.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical transfer | Chemical reaction |

| Temperature Range | 250°C - 450°C | 450°C - 1050°C+ |

| Coating Coverage | Line-of-sight (shadows possible) | Multidirectional (highly conformal) |

| Source Material | Solid target | Gaseous precursors |

| Best For | Temperature-sensitive materials, simple shapes | Complex 3D parts, high-purity films |

Need Expert Guidance on Your Coating Application?

Choosing between CVD and PVD can significantly impact your project's success. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision coating solutions.

Let our experts help you:

- Select the optimal deposition method for your specific material and geometry

- Ensure perfect coating conformity and performance

- Protect temperature-sensitive substrates from thermal damage

- Achieve the highest purity and density for your thin films

Contact us today to discuss your coating requirements and discover how our expertise can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process