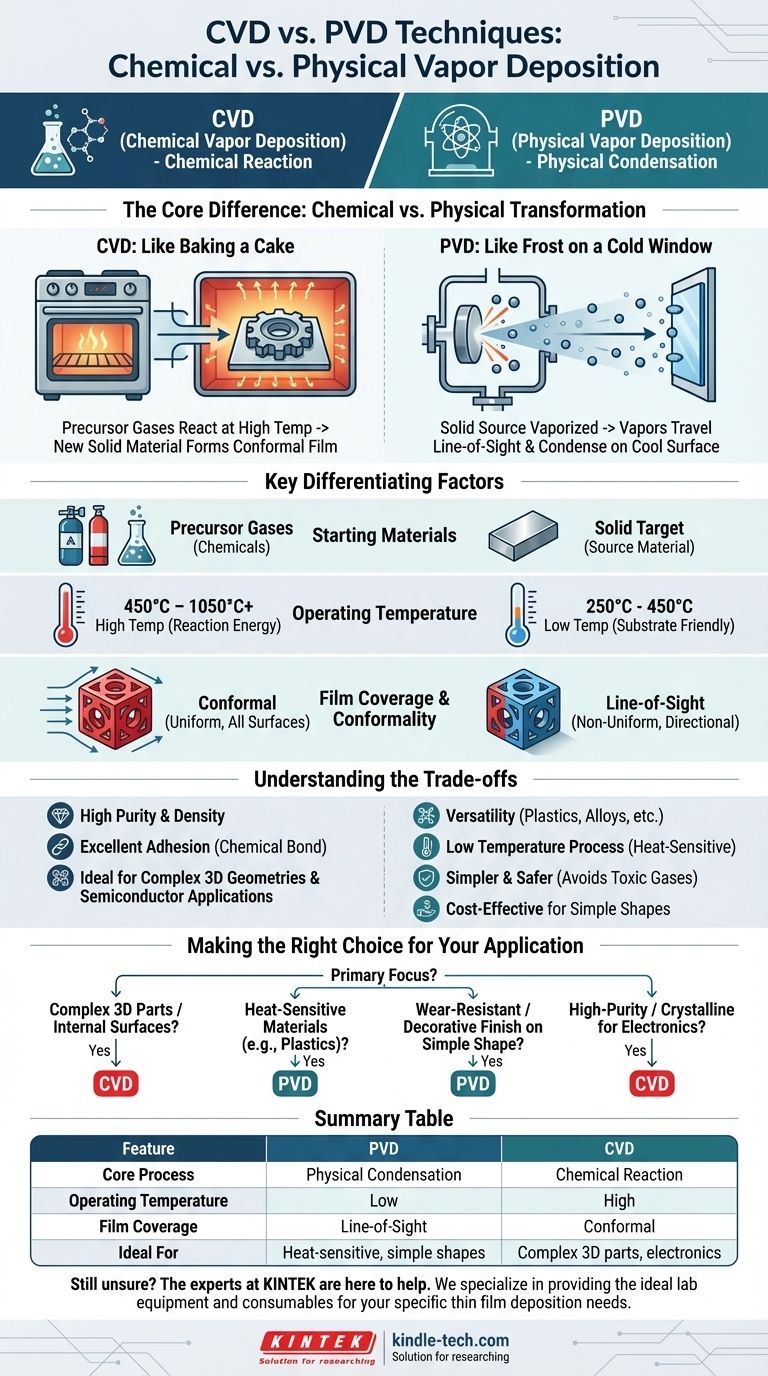

At its core, the difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) is a matter of chemical versus physical transformation. CVD uses chemical reactions between precursor gases to grow a film on a surface, while PVD physically transforms a solid or liquid source into a vapor that then condenses onto that surface.

The choice between PVD and CVD is not about which is universally "better," but about which fundamental process—physical condensation or chemical reaction—aligns with your specific material, geometry, and performance requirements. Understanding this distinction is the key to selecting the right tool for the job.

The Fundamental Process: Physical vs. Chemical

To truly grasp the difference, it's helpful to visualize how each process builds a thin film. They operate on entirely different principles.

PVD: A Physical Condensation Process

Think of PVD as being similar to frost forming on a cold window. Water vapor in the air (a gas) physically changes its state to become a solid layer of ice on the glass without any chemical reaction with the glass itself.

In PVD, a solid source material, known as a target, is vaporized inside a vacuum chamber. This is achieved through physical means like high-energy ion bombardment (sputtering) or by heating it until it evaporates (evaporation). These vaporized atoms then travel in a straight line and condense on the cooler substrate, forming a thin film.

CVD: A Chemical Reaction Process

CVD is more analogous to baking a cake. You mix gaseous ingredients (precursor gases) in a hot oven (a reactor chamber). The heat drives a chemical reaction between the gases, causing a new, solid material (the "cake") to form and deposit onto the surface of the "pan" (the substrate).

The resulting film is a completely new material created by the reaction, not just a condensed version of the starting material. The film is chemically bonded to the substrate, creating a very strong and durable coating.

Key Differentiating Factors Explained

The fundamental difference between a physical and chemical process creates several critical distinctions in their application and results.

Starting Materials

In PVD, the source material is typically a solid target of the exact material you want to deposit.

In CVD, the source is a combination of one or more precursor gases, which contain the chemical elements that will react to form the final film.

Operating Temperature

CVD is a high-temperature process, often running between 450°C and 1050°C or higher. This heat is necessary to provide the energy needed to drive the chemical reactions.

PVD is a comparatively low-temperature process, typically operating between 250°C and 450°C. High heat is not required for the physical condensation to occur, making it suitable for temperature-sensitive substrates.

Film Coverage and Conformality

This is one of the most significant practical differences. PVD is a line-of-sight process. Because the vaporized atoms travel in a straight line, it is very difficult to uniformly coat complex 3D shapes, sharp corners, or internal surfaces.

CVD, by contrast, is highly conformal. The precursor gases flow and diffuse around the substrate, allowing the chemical reaction to occur on all exposed surfaces simultaneously. This results in a highly uniform film, even on the most intricate geometries.

Understanding the Trade-offs

Neither method is inherently superior; they are simply different tools for different tasks. Your choice involves clear trade-offs.

The PVD Advantage: Versatility and Simplicity

The lower operating temperatures of PVD make it ideal for coating materials that cannot withstand high heat, such as plastics, certain alloys, and fully assembled components. The process can also be safer and simpler, as it often avoids the highly reactive or toxic precursor gases used in many CVD processes.

The CVD Advantage: Purity and Adhesion

CVD is unparalleled for producing extremely high-purity, dense films with excellent adhesion. The chemical bond formed with the substrate is typically stronger than the more mechanical bond of PVD films. This, combined with its conformal nature, makes it essential for demanding applications like semiconductor manufacturing.

The Gray Area: Reactive Processes

It's important to note that the lines can blur. For example, reactive sputtering is a PVD technique where a reactive gas (like nitrogen or oxygen) is introduced into the chamber. The sputtered metal atoms react with this gas mid-flight or on the substrate to form a compound film (like Titanium Nitride). This blends a physical process with a chemical one.

Making the Right Choice for Your Application

Selecting the correct method requires matching the process capabilities to your end goal.

- If your primary focus is coating a complex 3D part or an internal surface: CVD's conformal nature is the clear choice.

- If your primary focus is coating a heat-sensitive material like plastic: PVD's lower temperature process is the only viable option.

- If your primary focus is creating a wear-resistant or decorative finish on a relatively simple shape: PVD is often the most cost-effective and common solution.

- If your primary focus is growing a high-purity, crystalline film for electronics or semiconductors: CVD is the industry standard for its control and film quality.

Ultimately, understanding this core chemical versus physical difference transforms your decision from a simple comparison into a strategic choice aligned with your specific engineering goals.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Core Process | Physical condensation of vaporized material | Chemical reaction of precursor gases |

| Operating Temperature | Low (250°C - 450°C) | High (450°C - 1050°C+) |

| Film Coverage | Line-of-sight (less uniform) | Conformal (highly uniform) |

| Ideal For | Heat-sensitive materials, simpler shapes | Complex 3D parts, high-purity electronics |

Still unsure which deposition technique is right for your project? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment and consumables for your specific thin film deposition needs, whether you require the high conformity of CVD or the low-temperature versatility of PVD.

Contact our team today to discuss your application requirements and discover how KINTEK's solutions can enhance your laboratory's capabilities and ensure optimal results for your materials and performance goals.

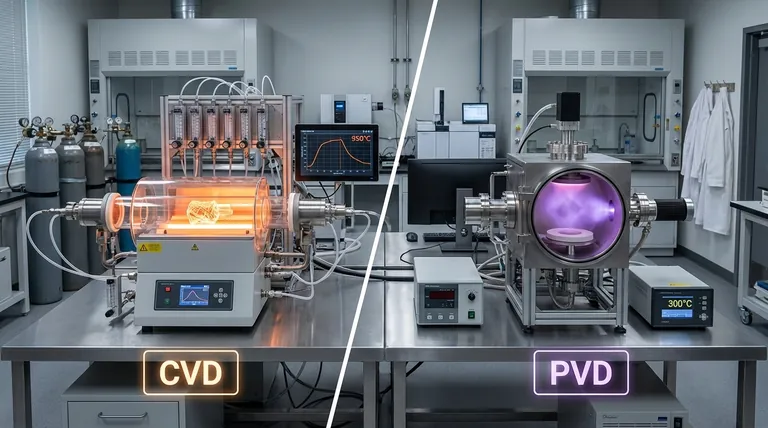

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process