At its core, the difference between sputtering and evaporation is one of force versus heat. Sputtering is a kinetic process that uses energetic ion bombardment to physically knock atoms off a source material, much like a sandblaster chipping away at a surface. In contrast, evaporation is a thermal process that involves heating a material in a vacuum until it boils and turns into a vapor, which then condenses onto a substrate to form a coating.

The choice between sputtering and evaporation is a classic engineering trade-off. Sputtering delivers superior film quality, adhesion, and uniformity at the cost of speed and complexity. Evaporation offers a faster, simpler, and more cost-effective method for applications where ultimate precision is not the primary driver.

Understanding the Core Mechanisms

To select the right method, you must first understand how each process works at an atomic level. The mechanism directly dictates the properties of the final film.

Sputtering: A Kinetic Process

Sputtering takes place in a vacuum chamber filled with an inert gas, such as argon. A high voltage is applied, creating a plasma.

Positively charged argon ions from this plasma are accelerated and collide with the source material, which is called the "target."

This high-energy bombardment has enough force to eject individual atoms from the target. These liberated atoms then travel through the chamber and deposit onto your substrate, forming a thin, dense film.

Evaporation: A Thermal Process

Evaporation also occurs in a high vacuum, but it relies on thermal energy. The source material is placed in a container (a "boat" or "crucible") and heated until it reaches its vaporization temperature.

As the material boils or sublimates, it releases a vapor stream of atoms. This vapor travels in a line-of-sight path until it makes contact with the cooler substrate, where it condenses back into a solid, forming the coating.

How Mechanism Dictates Film Properties

The high-energy nature of sputtered atoms gives them distinct advantages over the lower-energy atoms produced by thermal evaporation.

Adhesion and Density

Sputtered particles strike the substrate with significant kinetic energy. This causes them to embed slightly into the surface, resulting in adhesion strength that can be ten times greater than that of evaporated films.

This energy also means the atoms arrange themselves more tightly, creating films that are harder and denser than their evaporated counterparts.

Uniformity and Thickness Control

Sputtering allows for exceptionally fine control over the deposition rate. By precisely managing the plasma's power and gas pressure, you can achieve highly uniform films with repeatable thickness, which is critical for applications like optics and semiconductors.

Evaporation rates can be harder to control with the same level of precision, sometimes leading to variations in film thickness across the substrate.

Crystalline Structure and Temperature

Because sputtered atoms already possess high energy, they can form dense, crystalline film structures on substrates at lower temperatures.

Evaporation often requires heating the substrate to give the condensing atoms enough energy to form a well-ordered crystalline film. This makes sputtering a superior choice for coating heat-sensitive materials like plastics.

Understanding the Trade-offs

Neither method is universally superior. The decision to use one over the other involves balancing performance requirements against operational realities.

Deposition Speed

Evaporation typically produces a more robust vapor stream, enabling higher deposition rates and shorter run times. This makes it highly efficient for high-volume production.

Sputtering is an atom-by-atom ejection process, which generally results in slower deposition rates compared to evaporation.

Cost and System Complexity

Sputtering systems are inherently more complex. They require sophisticated power supplies to generate the plasma, advanced vacuum systems, and often magnetic fields to confine the plasma, leading to higher initial and operational costs.

Evaporation systems are mechanically simpler and therefore more cost-effective and easier to maintain.

Material Versatility

Sputtering excels at depositing a wide range of materials, including alloys and refractory metals, with excellent compositional control.

Evaporation can be challenging for materials with very high melting points or for alloys where different elements evaporate at different rates, potentially altering the film's final composition.

Making the Right Choice for Your Application

Your decision should be guided by your project's non-negotiable requirements. Use these guidelines to select the optimal process.

- If your primary focus is ultimate film quality and adhesion: Choose sputtering for its dense, uniform, and strongly bonded layers, ideal for medical devices, advanced optics, or semiconductor manufacturing.

- If your primary focus is high-volume production and cost-efficiency: Choose evaporation for its high deposition rates and lower system cost, suitable for decorative coatings or simple metallization.

- If you are working with heat-sensitive substrates: Sputtering is often the better choice, as it can produce high-quality films at much lower substrate temperatures.

- If you need to deposit complex alloys or compounds: Sputtering provides superior control over the stoichiometry (composition) of the final film.

By understanding these core principles, you can confidently select the deposition method that aligns perfectly with your technical and financial goals.

Summary Table:

| Feature | Sputtering | Evaporation |

|---|---|---|

| Process Type | Kinetic (force) | Thermal (heat) |

| Adhesion Strength | Very High | Standard |

| Film Density | High, Dense | Lower |

| Uniformity & Control | Excellent | Good |

| Deposition Speed | Slower | Faster |

| System Cost | Higher | Lower |

| Ideal For | High-quality optics, semiconductors, medical devices | Decorative coatings, simple metallization, high-volume production |

Still Unsure Which Coating Method is Best for Your Application?

Choosing between sputtering and evaporation is critical for achieving your project's performance and budget goals. The experts at KINTEK are here to help. We specialize in providing the right lab equipment and consumables for your specific coating needs, whether you require the superior film quality of sputtering or the cost-efficiency of evaporation.

Let us help you enhance your lab's capabilities. Contact our team today for a personalized consultation to discuss your requirements and find the perfect solution.

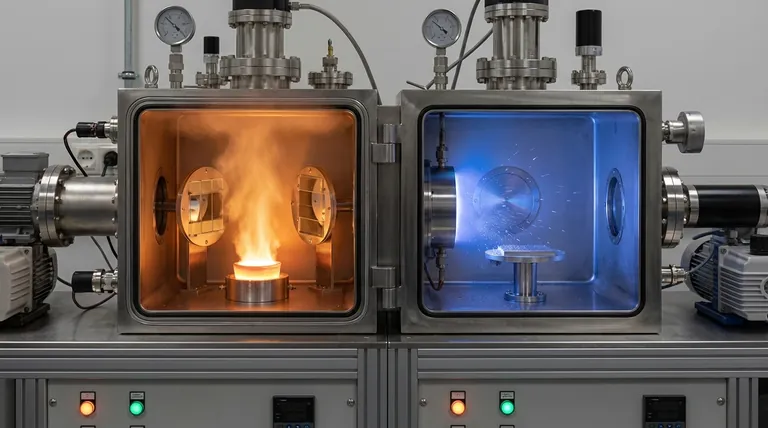

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems