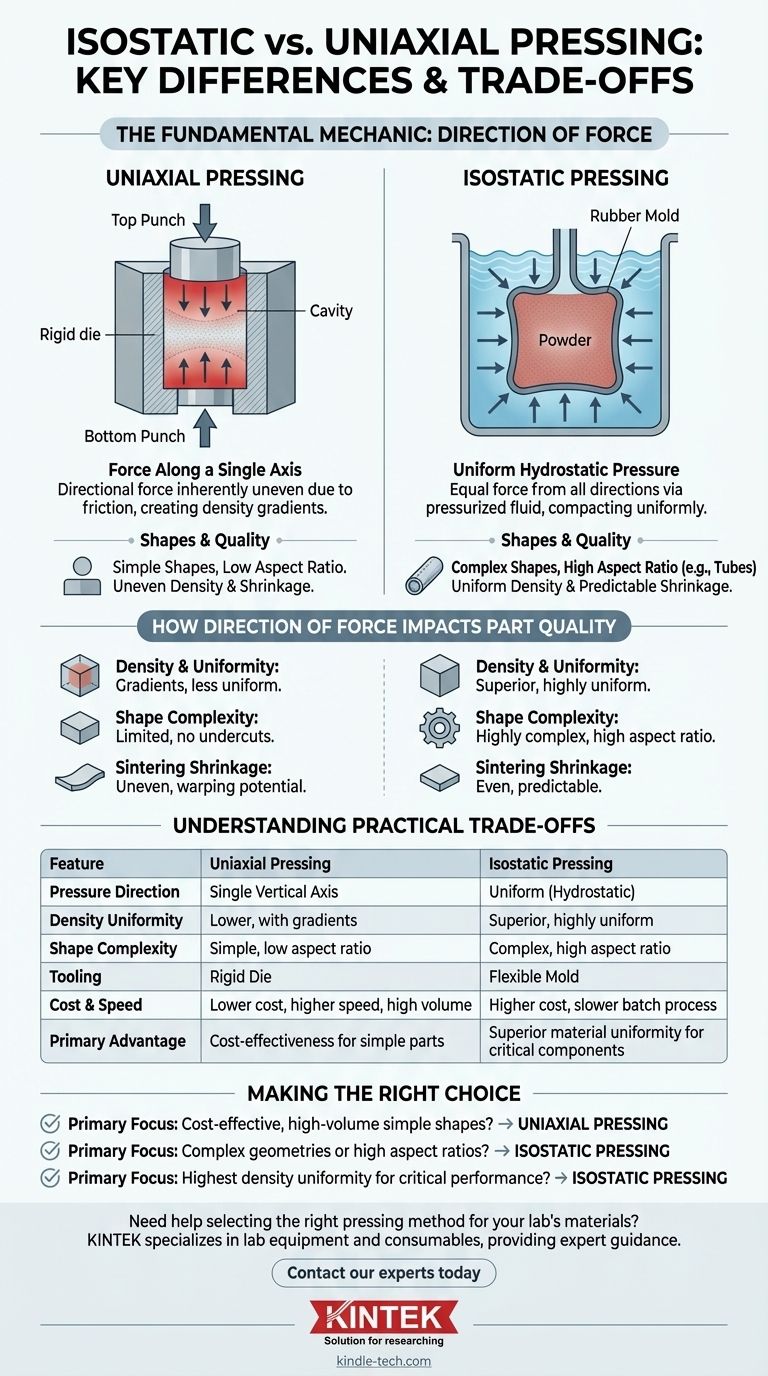

The fundamental difference lies in how pressure is applied. Uniaxial pressing compacts powder by applying force along a single vertical axis, typically using a top and bottom punch within a rigid die. In contrast, isostatic pressing uses a fluid to apply equal pressure from all directions simultaneously onto powder contained within a flexible mold.

While uniaxial pressing is a cost-effective, high-speed method for simple shapes, isostatic pressing provides superior density and form complexity by applying uniform pressure. This makes it the definitive choice for advanced components where material uniformity is critical.

The Fundamental Mechanic: Direction of Force

The method of applying pressure is the core distinction that dictates the capabilities and limitations of each process.

Uniaxial Pressing: Force Along a Single Axis

In this process, powder is placed in a rigid die cavity. A mechanical or hydraulic press then drives punches into the die from the top and/or bottom, compressing the powder along one axis.

This directional force is inherently uneven. Friction between the powder particles and the rigid die wall prevents pressure from being transmitted uniformly throughout the component, especially in taller parts.

Isostatic Pressing: Uniform Hydrostatic Pressure

This method encloses the powder in a sealed, flexible mold made of rubber or plastic. The mold is then submerged in a pressure vessel filled with a liquid, such as water or oil.

As the fluid is pressurized, it exerts an equal, simultaneous force on every surface of the flexible mold. This hydrostatic pressure compacts the powder uniformly from all directions.

How Direction of Force Impacts Part Quality

The difference in force application directly translates to significant differences in the final component's properties and geometry.

Density and Uniformity

Uniaxial pressing creates density gradients. The areas closest to the punches become denser, while the center and areas far from the punch remain less dense.

Isostatic pressing almost completely eliminates these gradients. The resulting "green" part (pre-sintering) has a remarkably uniform density, which is critical for predictable performance.

Shape Complexity and Aspect Ratio

Uniaxial pressing is limited to shapes that can be ejected from a rigid die, restricting it to relatively simple geometries with no undercuts.

Isostatic pressing’s flexible mold allows for the production of highly complex shapes. It also excels at creating parts with a high height-to-diameter ratio, such as long rods or tubes, which are impossible to form uniformly with uniaxial pressing. Spark plug insulators are a classic industrial example.

Shrinkage During Sintering

The final step for most compacted powders is sintering, where the part is heated to fuse the particles together. Uniform density from isostatic pressing leads to even, predictable shrinkage.

The density variations from uniaxial pressing can cause the part to shrink unevenly, leading to warping, cracking, or dimensional inaccuracy after sintering.

Understanding the Practical Trade-offs

Choosing a method requires balancing technical capability against economic and operational realities.

Tooling, Cost, and Speed

Uniaxial pressing is faster, more automated, and has significantly lower tooling and equipment costs. It is the standard for high-volume production of simple parts like tablets or basic ceramic tiles.

Isostatic pressing is a slower, more complex batch process with higher initial investment in equipment and tooling.

Dimensional Accuracy

Directly out of the press, uniaxial pressing offers excellent, highly repeatable dimensional control because the part is formed in a rigid, precisely machined die.

Isostatic pressing provides less direct dimensional control. Achieving a precise diameter or feature size may require iterative adjustments to the mold design and powder fill quantity. However, once optimized, the process is repeatable.

Ancillary Process Steps

Parts made via uniaxial pressing often require a wax binder to aid compaction, which must then be burned out in a separate, time-consuming dewaxing operation.

Isostatic pressing often eliminates the need for a binder, simplifying the overall manufacturing workflow and removing a potential source of defects.

Making the Right Choice for Your Goal

Your decision must be driven by the specific requirements of your component and production scale.

- If your primary focus is cost-effective, high-volume production of simple shapes: Uniaxial pressing is the optimal choice due to its speed, automation, and lower costs.

- If your primary focus is creating parts with complex geometries or high aspect ratios: Isostatic pressing is the necessary method to achieve these advanced forms.

- If your primary focus is achieving the highest possible density uniformity for predictable sintering and performance: Isostatic pressing is the superior technical solution.

By understanding these core trade-offs, you can confidently select the compaction method that aligns with your technical requirements and economic objectives.

Summary Table:

| Feature | Uniaxial Pressing | Isostatic Pressing |

|---|---|---|

| Pressure Direction | Single vertical axis | Uniform, from all directions (hydrostatic) |

| Density Uniformity | Lower, with gradients | Superior, highly uniform |

| Shape Complexity | Simple shapes, low aspect ratio | Complex shapes, high aspect ratio (e.g., rods, tubes) |

| Tooling | Rigid die | Flexible mold |

| Cost & Speed | Lower cost, higher speed, ideal for high volume | Higher cost, slower batch process |

| Primary Advantage | Cost-effectiveness for simple parts | Superior material uniformity for critical components |

Need help selecting the right pressing method for your lab's materials?

The choice between isostatic and uniaxial pressing is critical for achieving the desired density, shape, and performance in your components. KINTEK specializes in lab equipment and consumables, providing expert guidance to help you optimize your powder compaction processes.

Contact our experts today to discuss your specific application requirements and discover how our solutions can enhance your research and production outcomes.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the difference between HIP and CIP? A Guide to Shaping vs. Densification

- What products are made by isostatic pressing? Achieve Flawless, High-Performance Components

- What advantages does CIP equipment offer for W-TiC composites? Achieve High-Density, Defect-Free Materials

- What is the significance of the Cold Isostatic Press (CIP)? Optimize Lithium-Filled LLZO Composite Anode Preparation

- Why is a cold isostatic press preferred over a uniaxial press for tungsten powder? Achieve Uniform Powder Compaction

- What is CIP in powder metallurgy? Unlock Uniform Density for Complex Parts

- What types of materials are used for canisters in the HIP process? Optimized Choices for Material Densification

- What are the advantages of isostatic pressing? Achieve Superior Material Integrity and Design Freedom