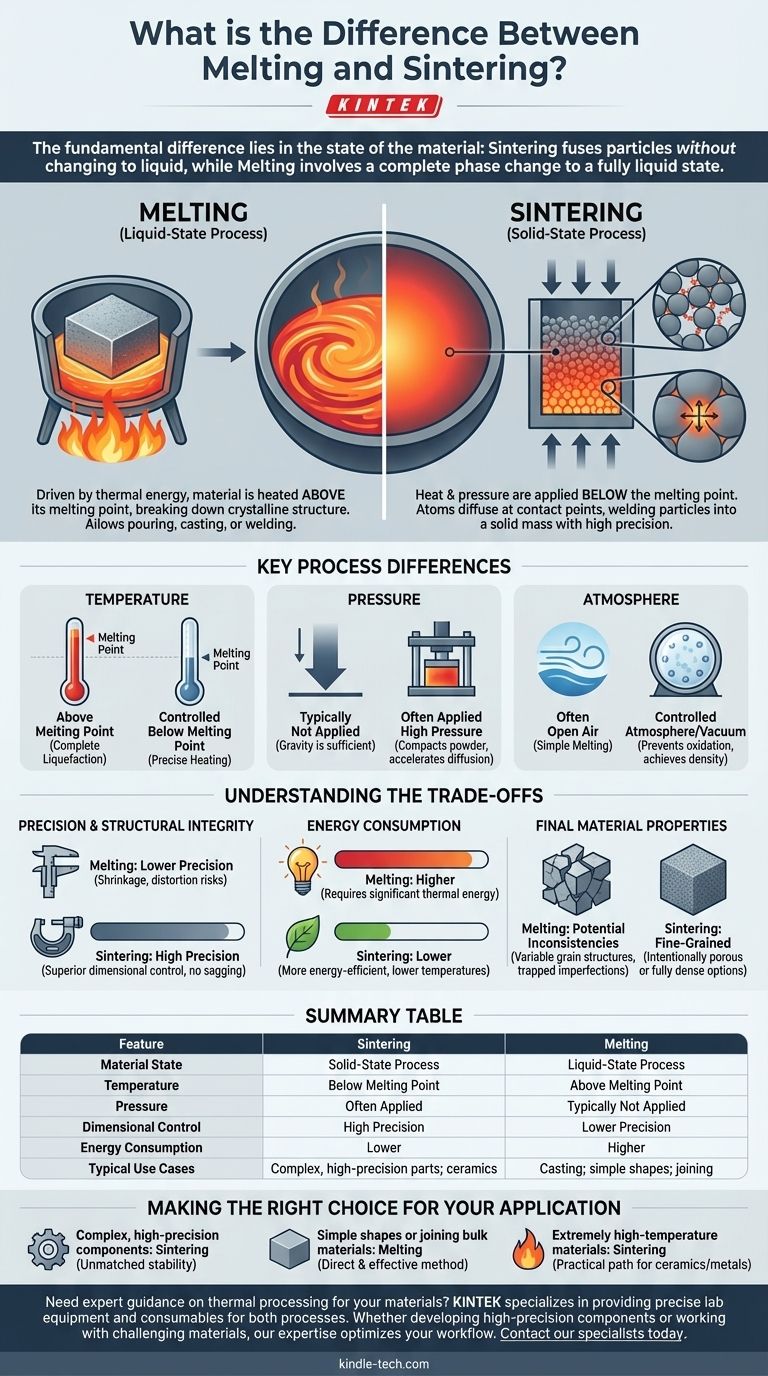

At a fundamental level, the difference between sintering and melting lies in the state of the material. Sintering is a process that uses heat and pressure to fuse particles together without changing the material from a solid to a liquid. In contrast, melting involves heating a material until it undergoes a complete phase change, transforming into a fully liquid state.

The critical distinction is that sintering is a solid-state process that offers high precision, while melting is a liquid-state process driven by pure thermal energy. This single difference dictates the energy required, the control you have over the final product, and the properties of the finished part.

The Core Mechanism: A Tale of Two States

The choice between these two thermal processes fundamentally alters how a material is formed and what its final characteristics will be. The core difference is whether the material's atomic structure is simply made mobile or completely broken down.

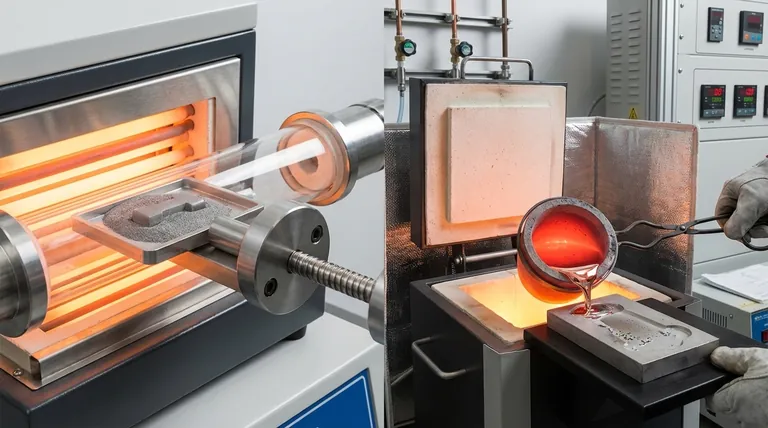

How Melting Works

Melting is a straightforward phase transition. A material is heated to a temperature above its melting point, causing its crystalline or amorphous structure to break down entirely.

The material becomes a liquid, allowing it to be poured, cast, or welded. The process relies solely on thermal energy to achieve this complete liquefaction.

How Sintering Works

Sintering is a more nuanced process that occurs below the melting point. It typically starts with a compacted powder of the desired material.

When heat and pressure are applied, atoms at the contact points of the powder particles become mobile. They diffuse across the boundaries, effectively welding the particles together into a solid mass without ever creating a bulk liquid.

Key Process Differences

Beyond the state of matter, the practical execution of these two methods involves different parameters that provide unique levels of control.

The Critical Role of Temperature

In melting, the goal is to exceed the melting point to ensure complete liquefaction. The exact temperature is less about precision and more about ensuring a full phase change.

In sintering, the temperature is carefully controlled to remain just below the melting point. Even slight overheating can cause unintended partial melting, which can damage the part's structure and dimensional accuracy.

The Application of Pressure

Melting generally does not require external pressure; gravity is sufficient for casting processes.

Sintering, however, frequently uses high pressure in conjunction with heat. This pressure compacts the initial powder, increases the contact points between particles, and accelerates the atomic diffusion that creates strong bonds.

The Need for a Controlled Atmosphere

While simple melting can often be done in the open air, many advanced sintering processes require a specific atmosphere.

Materials like metals, carbides, or nitrides are often sintered in a vacuum or under gases like hydrogen or nitrogen. This prevents oxidation and helps achieve a fully dense, pure final part.

Understanding the Trade-offs

Choosing between sintering and melting is a decision based on engineering trade-offs. Each process excels in different areas.

Precision and Structural Integrity

Sintering offers superior dimensional control. Because the part never becomes liquid, it is not prone to the sagging, slumping, or distortion that can occur during casting and cooling.

Melting can result in less dimensional accuracy due to shrinkage and internal stresses that form as the liquid material cools and solidifies.

Energy Consumption

As a rule, sintering is a more energy-efficient process. It operates at lower temperatures, requiring significantly less thermal energy than is needed to melt the same volume of material.

Final Material Properties

Sintering provides fine-grained control over the final microstructure. It can be used to create parts that are intentionally porous (for filters) or fully dense and exceptionally strong.

Melting and subsequent cooling can sometimes create inconsistent grain structures or trap imperfections within the solidified material.

Making the Right Choice for Your Application

The decision to use sintering or melting is driven entirely by the requirements of your final product and the materials you are using.

- If your primary focus is creating complex, high-precision components: Sintering is the superior choice for its unmatched dimensional stability and control over microstructure.

- If your primary focus is producing simple shapes or joining bulk materials: Melting is a direct and effective method, especially when intricate final dimensions are less critical.

- If your primary focus is working with extremely high-temperature materials: Sintering provides a practical path to form parts from ceramics or metals that are difficult or impossible to cast.

Ultimately, understanding this distinction—solid-state fusion versus liquid-state transformation—empowers you to select the manufacturing process that best aligns with your design goals.

Summary Table:

| Feature | Sintering | Melting |

|---|---|---|

| Material State | Solid-State Process | Liquid-State Process |

| Temperature | Below Melting Point | Above Melting Point |

| Pressure | Often Applied | Typically Not Applied |

| Dimensional Control | High Precision | Lower Precision |

| Energy Consumption | Lower | Higher |

| Typical Use Cases | Complex, high-precision parts; ceramics | Casting; simple shapes; joining |

Need expert guidance on thermal processing for your materials?

Choosing between sintering and melting is critical for achieving the desired properties in your final product. KINTEK specializes in providing the precise lab equipment and consumables needed for both processes. Whether you're developing high-precision components or working with challenging materials, our expertise can help you optimize your workflow for superior results.

Contact our specialists today to discuss your specific application and discover how KINTEK's solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is the role of a tube furnace in the thermal treatment of argyrodite electrolytes? Master Ionic Conductivity