The fundamental difference between plasma and thermal chemical vapor deposition (CVD) is the energy source used to drive the chemical reaction. Thermal CVD relies on high temperatures to provide the energy needed to break chemical bonds and form a solid film. In contrast, plasma-enhanced CVD (PECVD) uses an energized gas, or plasma, to initiate the reaction, allowing the process to occur at much lower temperatures.

Your choice between these two methods comes down to a critical factor: the heat tolerance of your substrate. Thermal CVD is excellent for robust materials, while plasma CVD's low-temperature operation is essential for depositing films on heat-sensitive materials like plastics or complex electronics.

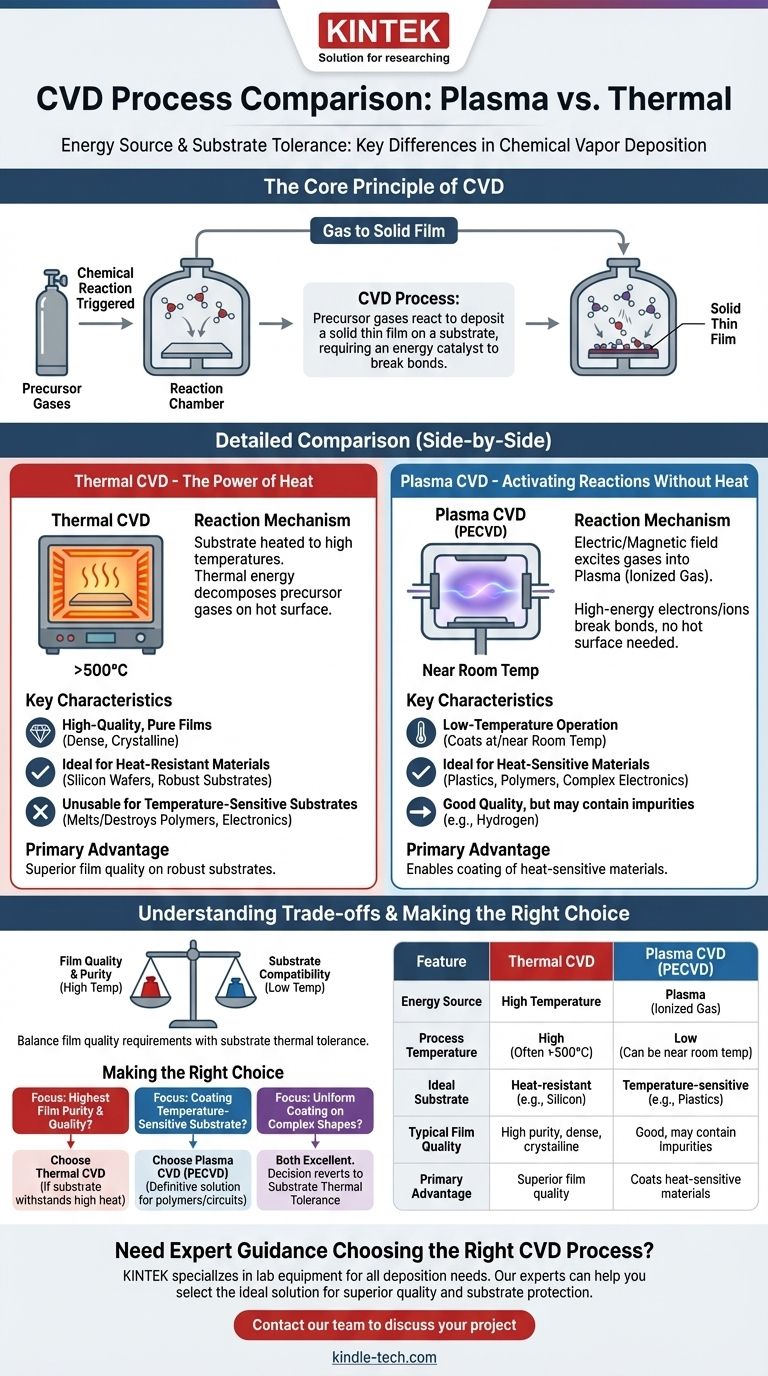

The Core Principle: How CVD Works

Chemical Vapor Deposition is a family of processes used to create high-quality, high-performance thin films on a substrate. The underlying principle is consistent across all variations.

From Gas to Solid Film

In any CVD process, precursor gases are introduced into a reaction chamber. These gases contain the elements you want to deposit. A chemical reaction is then triggered, causing a solid material from the gas to deposit onto the surface of your substrate, creating a thin film.

The Need for an Energy Catalyst

This chemical reaction doesn't happen on its own. It requires a significant amount of energy to break the chemical bonds within the precursor gases. The specific method used to supply this energy is what defines the different types of CVD.

Thermal CVD: The Power of Heat

Thermal CVD is the traditional and most straightforward approach. It uses heat as the sole energy source to drive the deposition reaction.

The Reaction Mechanism

The substrate is heated to very high temperatures, often several hundred or even over a thousand degrees Celsius. When the precursor gases come into contact with the hot surface, they gain enough thermal energy to decompose and react, depositing the desired film.

Key Characteristics

Thermal CVD, especially variants like LPCVD (Low-Pressure CVD), is known for producing high-quality, pure, and uniform films. The high temperature provides ample energy for atoms to arrange themselves into a dense and often crystalline structure. This makes it ideal for applications demanding the highest film quality on substrates that can withstand the heat.

Plasma CVD: Activating Reactions Without Heat

Plasma-Enhanced CVD (PECVD), also called Plasma-Assisted CVD (PACVD), was developed specifically to overcome the temperature limitations of thermal methods.

The Role of Plasma

Instead of relying on heat, PECVD uses a strong electric or magnetic field to excite the precursor gases into a plasma state. This plasma is a partially ionized gas containing a mix of neutral particles, ions, and high-energy electrons.

How Plasma Breaks Bonds

It's the high-energy electrons and ions within the plasma that do the work. They collide with the precursor gas molecules, possessing more than enough energy to break their chemical bonds and create reactive radicals. These highly reactive species then settle on the substrate to form the film, all without requiring a hot surface.

Key Characteristics

The defining advantage of plasma CVD is its low-temperature operation. Since the energy is supplied by the plasma, not by heating the substrate, deposition can occur at or near room temperature. This makes it possible to coat materials that would melt, deform, or be destroyed in a thermal CVD process.

Understanding the Trade-offs

The choice between thermal and plasma CVD is not just about temperature; it involves a balance of film quality, material compatibility, and process complexity.

The Temperature vs. Quality Balance

While plasma CVD is incredibly versatile, the films produced can sometimes be less dense or contain more impurities (like hydrogen) compared to those from high-temperature thermal CVD. The extreme heat of thermal processes often yields a more perfect, crystalline film structure that is difficult to achieve at low temperatures.

Substrate Limitations

This is the most critical trade-off. Thermal CVD is unusable for temperature-sensitive substrates. Attempting to coat a polymer, a finished electronic component, or certain biological materials with thermal CVD would result in damage or destruction. Plasma CVD is often the only viable option in these cases.

General CVD Advantages

It's important to note that both methods share the core advantages of CVD over other techniques like Physical Vapor Deposition (PVD). Both can create highly conformal coatings on complex, non-uniform shapes, overcoming the "line-of-sight" limitations common to PVD.

Making the Right Choice for Your Application

Selecting the correct CVD method requires you to prioritize your most important outcome.

- If your primary focus is the highest possible film purity and crystalline quality: Thermal CVD is often the superior choice, provided your substrate can withstand the high process temperatures.

- If your primary focus is coating a temperature-sensitive substrate: Plasma CVD (PECVD) is the definitive and often only solution for depositing films on polymers, assembled circuits, or plastics.

- If your primary focus is achieving a uniform coating on a complex shape: Both methods are excellent, and the decision will revert back to the thermal tolerance of your specific part.

Ultimately, your substrate's thermal budget is the primary factor that dictates which CVD energy source is right for your goal.

Summary Table:

| Feature | Thermal CVD | Plasma CVD (PECVD) |

|---|---|---|

| Energy Source | High Temperature | Plasma (Ionized Gas) |

| Process Temperature | High (Often >500°C) | Low (Can be near room temperature) |

| Ideal Substrate | Heat-resistant materials (e.g., silicon wafers) | Temperature-sensitive materials (e.g., plastics, electronics) |

| Typical Film Quality | High purity, dense, often crystalline | Good, but may contain more impurities |

| Primary Advantage | Superior film quality on robust substrates | Enables coating of heat-sensitive materials |

Need expert guidance choosing the right CVD process for your specific application?

At KINTEK, we specialize in lab equipment and consumables for all your deposition needs. Whether you require the high-temperature precision of thermal CVD or the versatile, low-temperature capabilities of plasma CVD, our experts can help you select the ideal solution to achieve superior film quality and protect your substrates.

Contact our team today to discuss your project requirements and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vertical Laboratory Tube Furnace

People Also Ask

- What is a PECVD system? A Guide to Low-Temperature Thin Film Deposition

- What is Plasma Enhanced Chemical Vapour Deposition (PECVD)? High-Quality Film Coating at Low Temperatures

- What is plasma assisted deposition process? Enable Low-Temperature, High-Quality Thin Films

- What are the potential disadvantages of PECVD? Manage Plasma Bombardment and Prevent Material Damage

- What is the temperature at which the PECVD is carried out? Optimize Your Thin Film Deposition Process

- What types of materials can be deposited using PECVD? Discover Versatile Thin Film Solutions for Your Lab

- What is DLC coating used for? Boost Component Performance with Extreme Hardness & Low Friction

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures