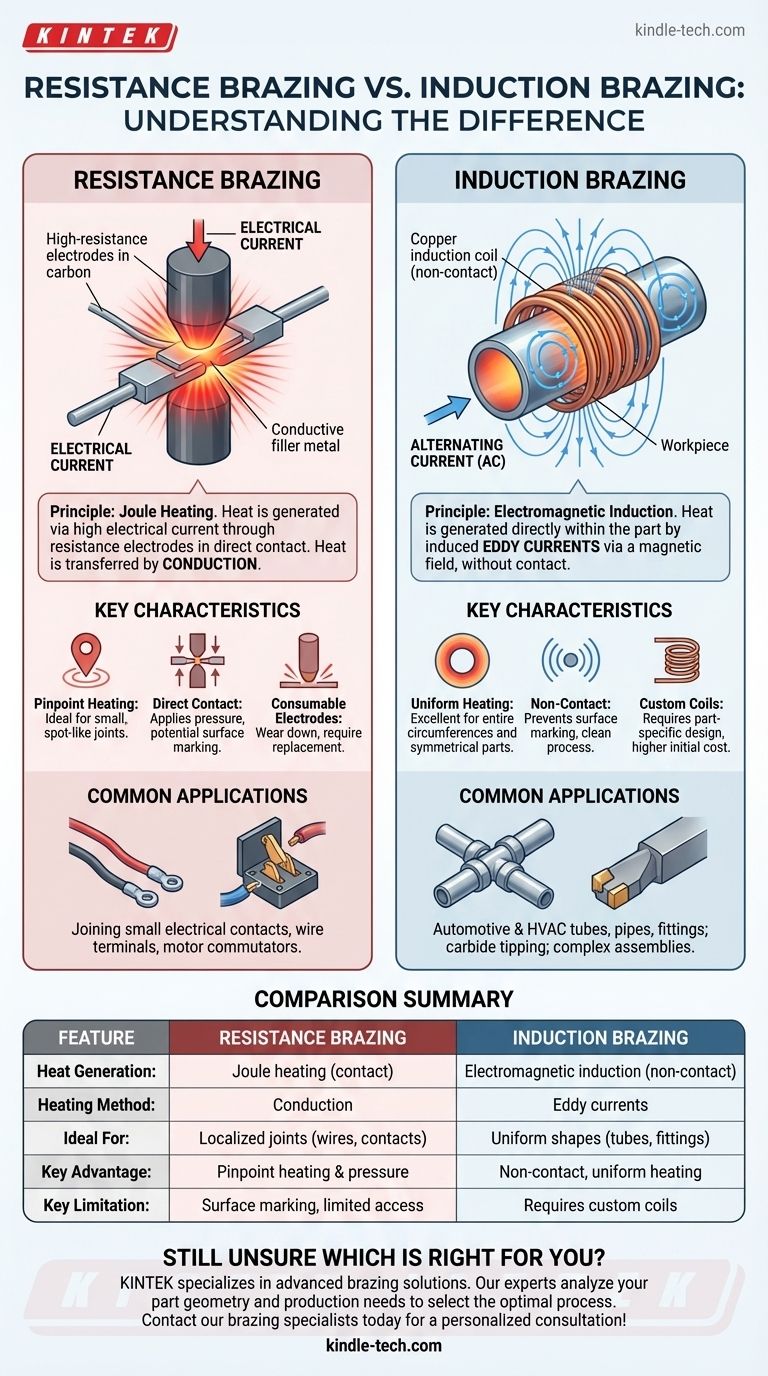

At its core, the difference between resistance brazing and induction brazing is how they generate heat. Resistance brazing heats the joint by passing an electrical current through high-resistance electrodes that are in direct contact with the workpiece. In contrast, induction brazing uses a non-contact method, heating the part directly by inducing electrical currents within it via a magnetic field.

The choice between these two advanced brazing methods is not about which is "better," but which is more appropriate for your part's geometry and production needs. Resistance brazing is ideal for localized, spot-like joints, while induction is superior for heating uniform shapes and complete joint perimeters without contact.

The Principle of Heat Generation

To select the right process, you must first understand the fundamental physics behind how each one creates heat. The method of heat generation dictates everything from cycle time to tooling cost.

How Resistance Brazing Works

Resistance brazing operates on the principle of Joule heating. A high electrical current is passed through electrodes, typically made of carbon or molybdenum, that clamp onto the parts being joined.

These electrodes have high electrical resistance, causing them to heat up intensely. This heat is then transferred to the workpiece and the braze alloy primarily through conduction, melting the filler metal.

The heat is highly localized to the points where the electrodes make contact.

How Induction Brazing Works

Induction brazing uses electromagnetic induction. An alternating current (AC) is passed through a precisely shaped copper coil, which creates a powerful, oscillating magnetic field.

When the workpiece is placed inside this field (without touching the coil), the field induces circulating electrical currents, known as eddy currents, within the part itself. The part's own electrical resistance causes it to heat up rapidly and uniformly from within.

Comparing Key Process Characteristics

The different heating principles lead to distinct process characteristics, each with advantages for specific applications.

Heat Application and Control

Resistance brazing provides pinpoint heating directly at the electrode contact points. This is excellent for small components but can lead to uneven heating on larger joints.

Induction heating is defined by the shape of the coil. It excels at heating entire circumferences, such as a tube in a fitting, with exceptional uniformity and repeatability. The process is non-contact, which prevents marking the part surface.

Speed and Cycle Times

Both methods are extremely fast and well-suited for automation. A typical cycle can be completed in a matter of seconds.

Induction is often faster for heating a complete joint area, while resistance can be quicker for tiny, spot-like connections where the electrodes can clamp and heat almost instantly.

Equipment and Tooling

Resistance brazing requires a power supply and a set of consumable electrodes. These electrodes wear down over time and must be replaced, and their shape is critical to the joint quality.

Induction brazing requires a power supply and a custom-designed induction coil for each specific part geometry. While coils are durable, the initial design and fabrication can represent a significant tooling investment.

Understanding the Trade-offs and Applications

Neither method is a universal solution. The geometry of your part and the nature of your production line will guide your decision.

Common Applications for Resistance Brazing

This method is the go-to choice for joining small, conductive components in high volumes.

Classic examples include attaching wires to terminals, connecting electrical contacts in switches and relays, and brazing segments onto motor commutators. The ability to apply both heat and pressure simultaneously is a key benefit.

Common Applications for Induction Brazing

Induction is dominant where joint integrity, speed, and cosmetic appearance are critical, especially on symmetrical parts.

It is widely used in the automotive and HVAC industries for brazing tubes, pipes, and fittings. It's also used for carbide tipping on cutting tools and joining complex assemblies where uniform heating is essential.

Key Limitations to Consider

The main limitation of resistance brazing is its reliance on physical contact, which can mar surfaces and limits access to joints. It is also less effective for heating large or non-uniform areas evenly.

The primary drawback of induction brazing is the need for part-specific coils. A change in part design requires a new coil, adding cost and lead time, making it less flexible for low-volume or highly varied production.

Making the Right Choice for Your Application

Selecting the optimal method requires matching the process capabilities to your specific manufacturing goal.

- If your primary focus is high-volume production of small electrical contacts or wire terminals: Resistance brazing offers unmatched efficiency and precision for these specific joint types.

- If your primary focus is creating clean, strong, and repeatable joints on tubular or symmetrical parts: Induction brazing provides superior control, speed, and quality for these geometries.

- If your primary focus is avoiding surface marks while heating a precise area: Induction brazing's non-contact nature makes it the clear choice.

By understanding how each process generates heat, you can confidently select the method that delivers the most reliable and cost-effective solution for your product.

Summary Table:

| Feature | Resistance Brazing | Induction Brazing |

|---|---|---|

| Heat Generation | Joule heating via electrode contact | Electromagnetic induction (non-contact) |

| Heating Method | Conduction from electrodes | Eddy currents within the part |

| Ideal For | Localized, spot-like joints (e.g., wires, contacts) | Uniform shapes & complete joint perimeters (e.g., tubes, fittings) |

| Key Advantage | Pinpoint heating, applies pressure | Non-contact, uniform heating, excellent repeatability |

| Key Limitation | Surface marking, less effective for large areas | Requires custom coil for each part geometry |

Still unsure which brazing method is right for your application?

KINTEK specializes in providing advanced brazing solutions and lab equipment. Our experts can help you analyze your part geometry and production requirements to select the optimal process, ensuring strong, reliable joints and maximum efficiency.

Contact our brazing specialists today for a personalized consultation!

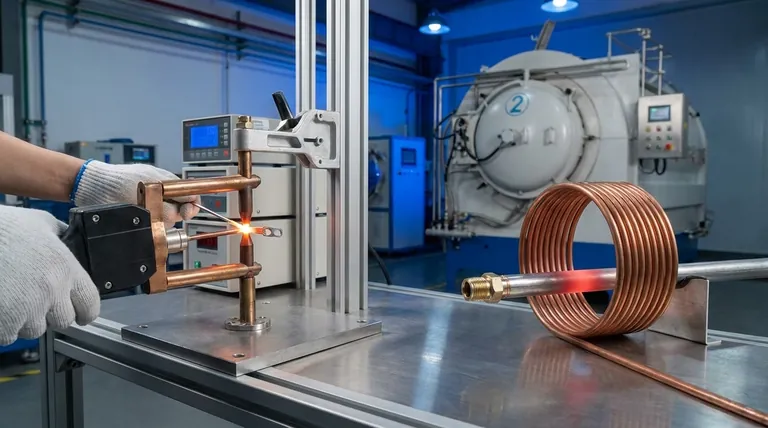

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries