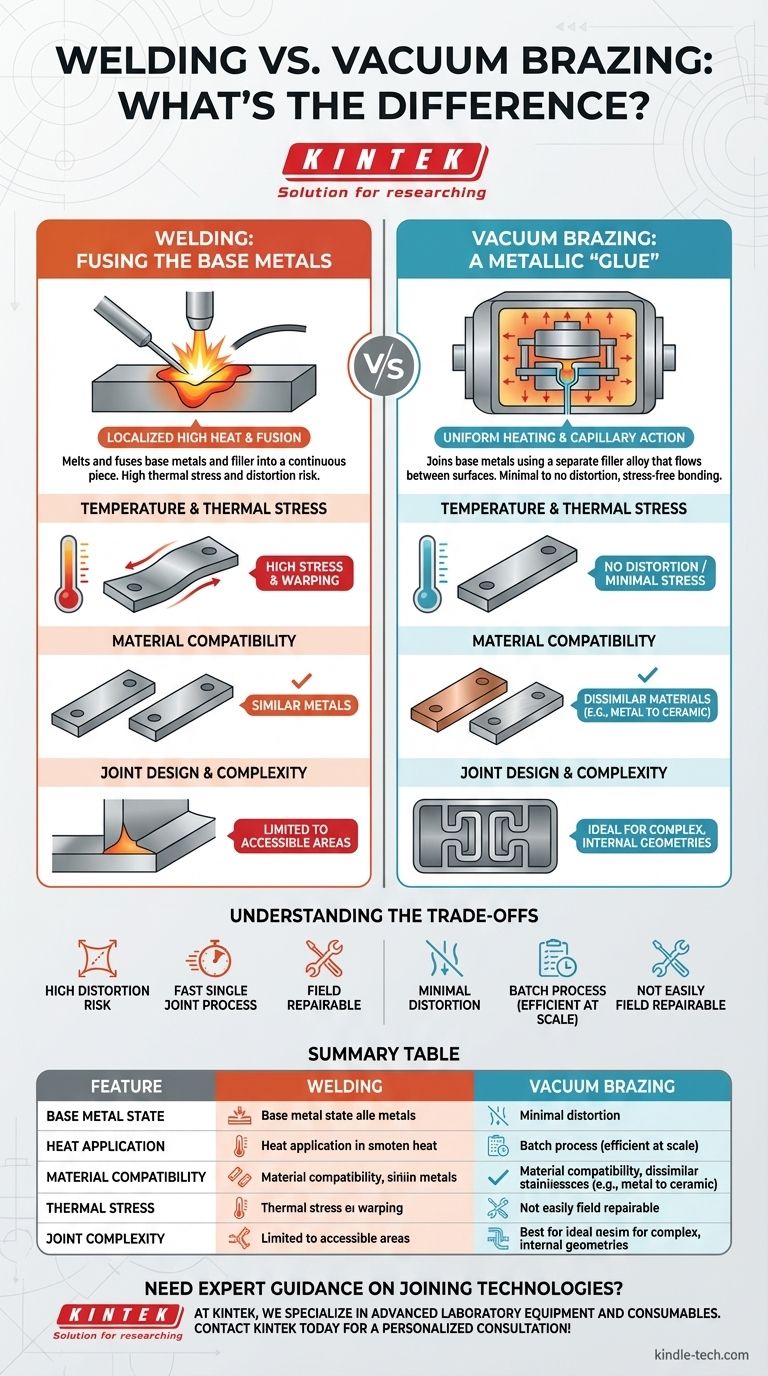

At its core, the difference between welding and vacuum brazing lies in how they join materials. Welding melts and fuses the base metals together, creating a single, continuous piece. In contrast, vacuum brazing joins metals using a separate filler alloy that melts at a lower temperature, flowing between the closely fitted surfaces without melting the base materials, all within a high-vacuum environment.

While both create strong metallic bonds, the fundamental choice is between welding's localized fusion for raw strength and vacuum brazing's uniform, stress-free bonding for complex and sensitive assemblies.

The Core Mechanism: Melting vs. Capillary Action

To understand the practical implications, you must first grasp the physics behind each process. They are fundamentally different methods of achieving a metallurgical bond.

Welding: Fusing the Base Metals

Welding introduces intense, localized energy (like an electric arc or a laser) to a specific point.

This extreme heat melts the edges of the parent materials, often along with a filler rod of a similar composition. These molten pools then mix and solidify, forming a joint that is a continuous part of the base metal.

Brazing: A Metallic "Glue"

Brazing works more like a high-strength soldering process. The parts to be joined are designed with a very small, uniform gap between them.

A filler metal (the brazing alloy) with a lower melting point is placed in or near the joint. The entire assembly is then heated in a furnace to a temperature above the filler's melting point but below the base materials' melting point.

The molten filler is then pulled through the entire joint by a force called capillary action, creating a complete and uniform bond upon cooling.

The Role of the Vacuum

Performing this process in a vacuum furnace is what makes "vacuum brazing" so powerful. The low-pressure environment (typically near one-millionth of atmospheric pressure) acts as a perfect shield.

It prevents the formation of oxides that would otherwise interfere with the bond, eliminating the need for corrosive chemical fluxes. The vacuum also pulls impurities and trapped gases out of the metal itself, resulting in an exceptionally clean, strong, and hermetically sealed joint.

Comparing Key Process Characteristics

The choice between welding and vacuum brazing depends entirely on your design goals, materials, and final application.

Temperature and Thermal Stress

Welding's high, localized heat creates steep thermal gradients. This rapid heating and cooling can cause distortion, warping, and high residual stress in the final part, often requiring a secondary stress-relief heat treatment.

Vacuum brazing heats the entire assembly slowly and uniformly in the furnace. This eliminates thermal stress, making it the ideal choice for dimensionally critical components that cannot tolerate any warping.

Material Compatibility

Welding is typically used to join similar metals (steel to steel, aluminum to aluminum). Joining dissimilar metals is challenging and often results in brittle, unreliable joints.

Vacuum brazing excels at joining dissimilar materials. Because the base metals never melt, you can successfully bond materials like copper to stainless steel, or even metals to ceramics, which is impossible with conventional welding.

Joint Design and Complexity

A weld is limited to a line-of-sight path accessible by the welding tool. It is difficult to create reliable welds on internal or hidden features.

Brazing allows for joining large surface areas and highly complex geometries. As long as a capillary gap exists, the filler metal will flow and create a bond, making it perfect for intricate assemblies like heat exchangers or honeycomb structures.

Understanding the Trade-offs

Neither process is universally superior; each comes with clear limitations you must respect.

Risk of Distortion and Cracking

Welding is inherently a high-stress process. The risk of distortion is always present, especially on thin or complex parts. This often necessitates heavy fixturing or post-process machining to correct.

The primary limitation of vacuum brazing is that the entire assembly must be able to withstand the furnace temperature. This requires careful material selection for all components, not just those near the joint.

Process Speed vs. Batch Processing

For a single, simple joint, welding is much faster. A welder can complete a joint in minutes.

Vacuum brazing is a batch process. A single furnace cycle can take many hours. However, a large furnace can process hundreds or even thousands of parts in a single run, making its "per-part" time extremely low for high-volume production.

Repairability and Field Use

Welding is highly portable and is the standard for on-site fabrication and repair. A broken weld on a steel structure can be easily ground out and re-welded in the field.

A brazed joint cannot be easily repaired in the same way. Repairing a brazed assembly typically requires a new furnace cycle, making it unsuitable for field applications.

Making the Right Choice for Your Application

Selecting the correct process requires aligning its strengths with your most critical project requirement.

- If your primary focus is maximum localized strength or field repairability: Welding is the superior choice for its direct fusion of parent metals.

- If your primary focus is joining complex, dissimilar, or dimensionally sensitive materials without distortion: Vacuum brazing is the definitive solution for its stress-free, uniform heating.

- If your primary focus is creating hundreds of clean, hermetic joints on intricate assemblies: Vacuum brazing offers unmatched quality and efficiency at scale.

Ultimately, understanding this distinction between localized fusion and holistic bonding empowers you to select the precise manufacturing process for a flawless result.

Summary Table:

| Feature | Welding | Vacuum Brazing |

|---|---|---|

| Base Metal State | Melted and fused | Remains solid |

| Heat Application | Localized, high temperature | Uniform, lower temperature |

| Material Compatibility | Best for similar metals | Excellent for dissimilar materials |

| Thermal Stress | High risk of distortion and warping | Minimal to no distortion |

| Joint Complexity | Limited to accessible areas | Ideal for complex, internal geometries |

| Process Environment | Ambient or shielded gas | High-vacuum environment |

| Best For | Maximum localized strength, field repairs | Complex assemblies, sensitive materials, high-volume production |

Need Expert Guidance on Joining Technologies?

Choosing between welding and vacuum brazing can significantly impact your project's success. At KINTEK, we specialize in providing advanced laboratory equipment and consumables for material joining applications. Our expertise helps you:

- Select the right process for your specific materials and design requirements

- Optimize joint quality with precision-controlled heating solutions

- Improve production efficiency with reliable, high-performance equipment

- Solve complex joining challenges for dissimilar materials and intricate designs

Whether you're working with heat exchangers, aerospace components, or precision instruments, KINTEK has the solutions and support you need. Let our specialists help you achieve flawless results.

Contact KINTEK today for a personalized consultation on your joining technology needs!

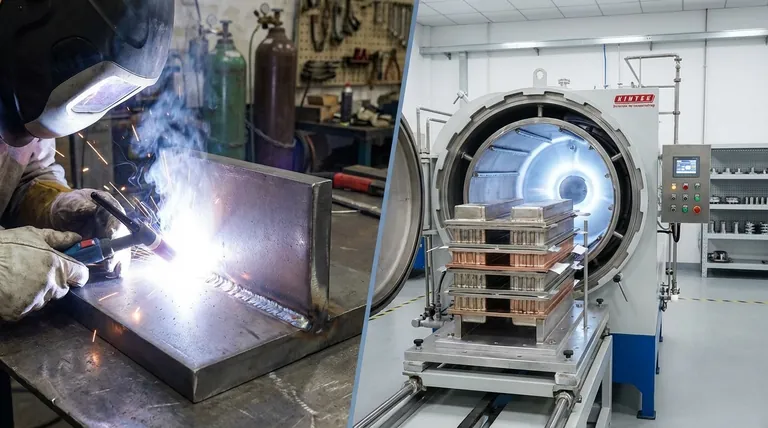

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of using a vacuum drying oven? Ensure Oxidation-Free Moisture Removal for Graphite Films

- Where is vacuum furnace used? Essential for Aerospace, Medical, and High-Tech Manufacturing

- What is the advantage of resistance furnace? Achieve Superior Control and Cleanliness

- What is the temperature sintering of alumina? Unlock Superior Performance with 1500°C to 1700°C

- What is a pyrolysis furnace? A Tool for Converting Waste into Valuable Resources

- What are the different design schemes and common mediums used for gas cooling in vacuum furnaces? Optimize Your Heat Treatment Process

- What role do industrial-grade high-temperature sintering furnaces play in the final formation of Lanthanum Zirconate?

- What are the advantages of metal sintering? Achieve Cost-Effective, Complex Metal Parts