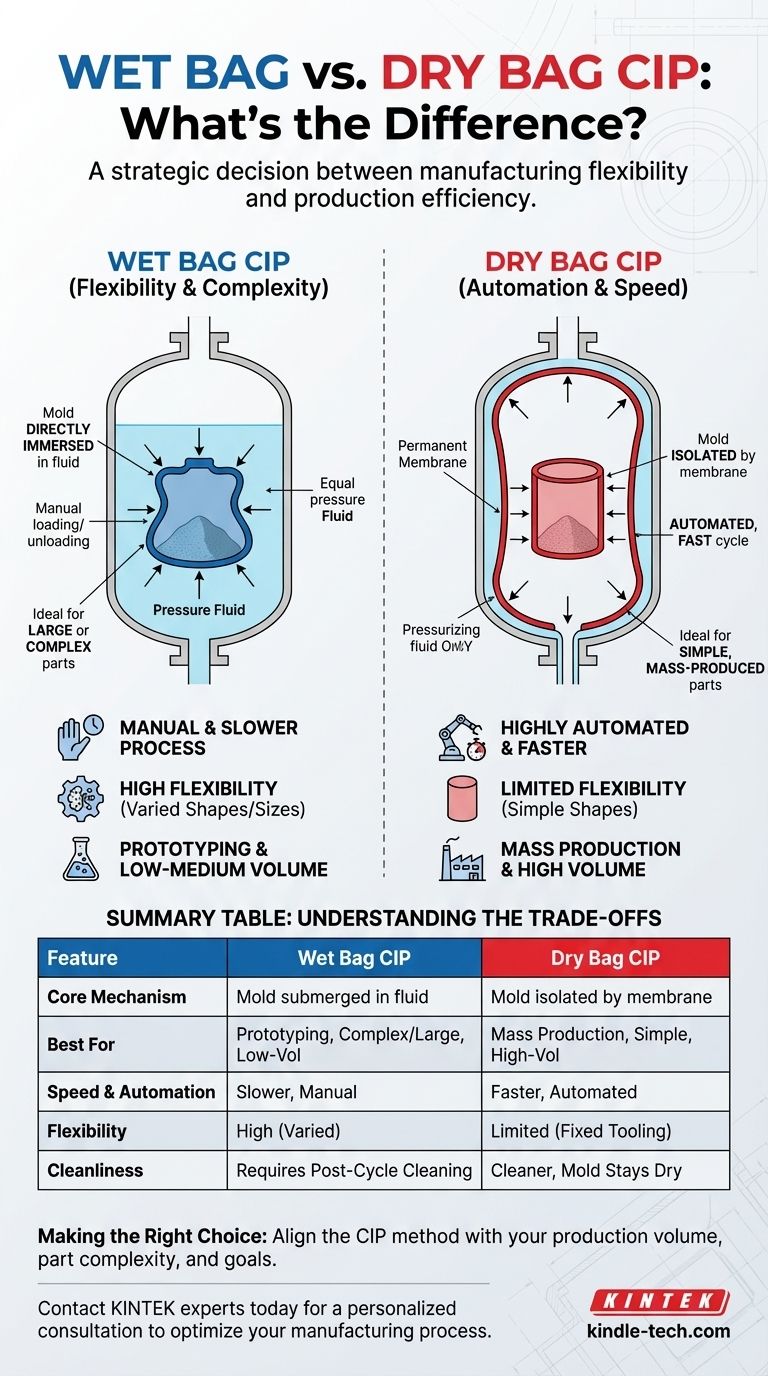

The fundamental difference between wet bag and dry bag Cold Isostatic Pressing (CIP) lies in how the powder-filled mold interacts with the pressurizing fluid. In the wet bag process, the sealed mold is directly immersed in the fluid, while in the dry bag process, the mold is isolated from the fluid by a permanent, flexible membrane built into the pressure vessel. This single distinction dictates the applications, speed, and automation potential of each method.

Your choice between wet and dry bag CIP is a strategic decision between manufacturing flexibility and production efficiency. The wet bag process offers maximum versatility for complex or large parts, whereas the dry bag process is engineered for high-volume, automated production of simpler shapes.

The Wet Bag Process: Flexibility and Complexity

The wet bag method is the more traditional and manual of the two CIP processes. It provides exceptional flexibility for a wide range of product shapes and sizes.

The Core Mechanism

In this process, powder is filled into a flexible mold, which is then sealed to be airtight. This entire sealed mold assembly is placed directly into a pressure vessel and submerged in a pressure medium, typically water or oil. Isostatic pressure is then applied equally to all surfaces of the mold, compacting the powder inside.

Key Characteristics

The primary characteristic of the wet bag process is its manual nature. Each mold must be filled, sealed, loaded into the vessel, and then removed and cleaned after each cycle. This makes the process inherently slower than its dry bag counterpart.

Typical Applications

This method is ideal for prototyping, research, and small-to-medium production runs. Its major advantage is the ability to produce very large or geometrically complex parts, as the tooling is not constrained by a built-in vessel membrane.

The Dry Bag Process: Automation and Speed

The dry bag process was developed to overcome the manual limitations of the wet bag method, enabling high-speed, automated production lines.

The Core Mechanism

In a dry bag press, a durable, flexible membrane is a permanent part of the pressure vessel itself. This membrane isolates the pressurizing fluid from the tooling. The powder is filled into a mold, which is then placed inside this "dry bag" membrane. The pressure is applied to the outside of the membrane, which in turn compresses the mold.

Key Characteristics

Because the mold never comes into contact with the pressure fluid, the process is much cleaner and faster. The cycle can be highly automated, as molds are simply inserted and removed from the dry chamber, saving significant labor and cleaning time.

Typical Applications

The dry bag process is perfectly suited for mass production of a limited variety of simple shapes. Think of components like spark plug insulators or small cylinders, where millions of identical parts are needed and cycle time is a critical cost factor.

Understanding the Trade-offs

The decision to use wet bag or dry bag CIP is not about which is "better," but which is appropriate for the manufacturing goal. The trade-offs are clear and direct.

Production Volume and Speed

Dry bag is the clear winner for speed and volume. Its rapid, automated cycles are designed for mass production. Wet bag is slower due to the manual handling of each mold, making it suitable for lower-volume needs.

Shape Complexity and Size

Wet bag offers superior flexibility for shape and size. Since the mold is independent of the vessel, it can be used for exceptionally large or intricate designs. Dry bag is limited to simpler geometries that can fit within the vessel's integrated membrane tooling.

Operational Process and Cleanliness

Dry bag is a cleaner, more streamlined operation. The mold stays dry, eliminating the need for post-cycle cleaning and reducing contamination risk. Wet bag requires extensive handling, including sealing the mold, submerging it, and cleaning both the mold and potentially the vessel.

Making the Right Choice for Your Goal

Select the process that directly aligns with your production volume, part complexity, and operational priorities.

- If your primary focus is prototyping or producing complex parts: Choose the wet bag process for its unmatched design freedom and flexibility.

- If your primary focus is high-volume mass production of simple parts: Choose the dry bag process for its speed, automation, and lower per-unit labor cost.

- If your primary focus is manufacturing very large-scale components: Choose the wet bag process, as the part size is not constrained by integrated tooling.

Ultimately, aligning the CIP method with your specific product and business goals is the key to successful implementation.

Summary Table:

| Feature | Wet Bag CIP | Dry Bag CIP |

|---|---|---|

| Core Mechanism | Mold is submerged in pressure fluid | Mold is isolated by a permanent membrane |

| Best For | Prototyping, complex/large parts, low-medium volume | Mass production, simple shapes, high volume |

| Speed & Automation | Slower, manual process | Faster, highly automated |

| Flexibility | High (varied shapes/sizes) | Limited (by fixed tooling) |

| Cleanliness | Requires post-cycle cleaning | Cleaner, mold stays dry |

Still unsure which CIP process is right for your lab's production goals?

KINTEK specializes in lab equipment and consumables, providing expert guidance and solutions for all your powder compaction needs. Whether you require the flexibility of wet bag CIP for complex prototypes or the high-speed efficiency of dry bag CIP for mass production, our team can help you select the ideal equipment to enhance your lab's productivity and output quality.

Contact our experts today for a personalized consultation and discover how KINTEK can optimize your manufacturing process!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is a cold isostatic press? Achieve Uniform Powder Compaction for Complex Parts

- What is the benefit of using a cold isostatic press for the secondary treatment of TiC10/Cu-Al2O3? Boost Density Now!

- What is the pressing method in ceramics? A Guide to Shaping Dense, High-Performance Parts

- What is the cold isostatic pressing method? Achieve Uniform Density in Complex Parts

- What are the advantages of the isostatic pressing process? Achieve High Density and Complex Geometries

- Why is isostatic pressing better than regular uniaxial pressing when manufacturing ceramics? Achieve Superior Density and Complex Shapes

- How does a cold isostatic press (CIP) address YAG ceramic density? Achieve Uniform High-Density Green Bodies

- What is isostatic pressing of polymers? Achieve Superior Uniform Density for High-Performance Parts