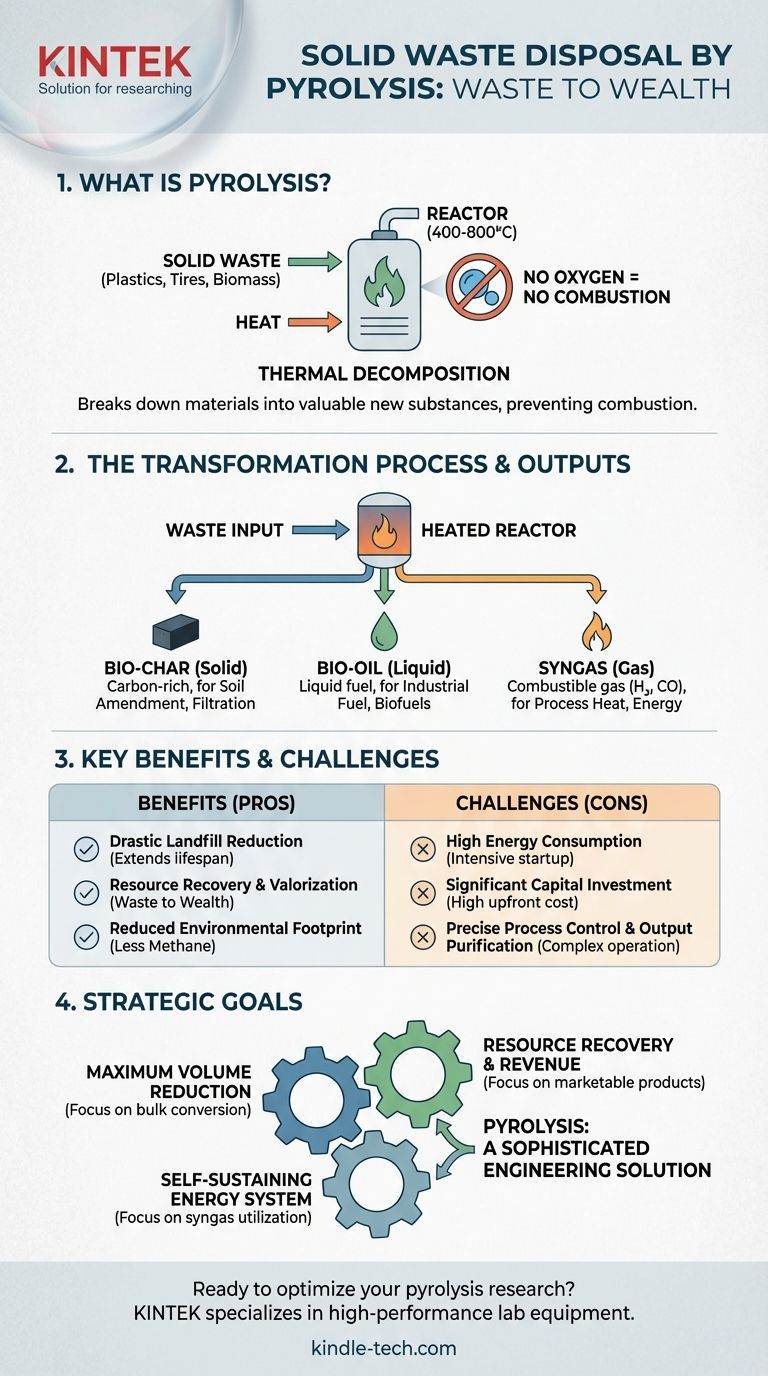

In essence, pyrolysis is the thermal decomposition of materials at high temperatures in an inert atmosphere. For solid waste, this means heating materials like plastics, old tires, or biomass in the absence of oxygen, which prevents them from combusting and instead breaks them down into valuable new substances.

While often seen as a waste disposal method, it is more accurate to view pyrolysis as a waste transformation or valorization technology. It converts low-value waste streams into higher-value products, but its practical application is governed by significant energy, technical, and economic challenges.

How Pyrolysis Transforms Waste

Pyrolysis fundamentally re-engineers waste at a molecular level. Unlike incineration, which uses oxygen to burn waste for heat, pyrolysis uses heat to break down complex organic materials without burning them.

The Core Principle: Heating Without Oxygen

The process involves heating waste to high temperatures (typically between 400-800°C or 750-1470°F) in a reactor vessel that is devoid of oxygen.

This absence of oxygen is the critical factor. It prevents combustion and forces the chemical compounds within the waste to break apart into simpler, more stable molecules.

The Three Primary Outputs

The decomposition process yields a mix of solids, liquids, and gases. These outputs must be separated and refined, but they represent a recovery of resources from the original waste.

- Bio-char (Solid): A stable, carbon-rich solid similar to charcoal. It can be used as a soil amendment to improve fertility, as a filtration medium, or as a feedstock for creating activated carbon.

- Bio-oil / Pyrolysis Oil (Liquid): A complex mixture of liquid organic compounds. After refining, it can be used as an industrial fuel or further processed into specialty chemicals and biofuels.

- Syngas (Gas): A mixture of combustible gases, primarily hydrogen and carbon monoxide. Syngas can be burned on-site to generate the heat needed to power the pyrolysis process itself, creating a partially self-sustaining system.

The Key Benefits of Pyrolysis

When successfully implemented, pyrolysis offers significant advantages over traditional landfilling, contributing to a more circular economy.

Drastic Landfill Reduction

Pyrolysis can significantly reduce the volume of non-recyclable waste that must be sent to landfills. This extends the life of existing landfills and reduces the need for new ones, which are often difficult to site.

Resource Recovery and Valorization

The process embodies the principle of "waste-to-wealth." It transforms materials otherwise considered garbage into marketable commodities like fuel, industrial chemicals, and agricultural products.

Reduced Environmental Footprint

By diverting waste from landfills, pyrolysis helps mitigate the release of methane, a potent greenhouse gas produced by decomposing organic matter. It also provides an alternative to open burning or less-controlled incineration methods.

Understanding the Trade-offs and Challenges

Despite its promise, pyrolysis is not a simple solution. Real-world implementation requires navigating significant technical and financial hurdles.

High Energy Consumption

Bringing a reactor to the required high temperatures is an energy-intensive process. While the syngas produced can offset some of this energy demand, the initial startup and process stabilization require a substantial external energy source.

Significant Capital Investment

Pyrolysis facilities involve high capital costs. The specialized reactors, gas handling systems, and equipment needed to separate and purify the end products represent a major upfront financial commitment.

The Need for Precise Process Control

Efficiency hinges on maintaining specific conditions. Factors like temperature, heating rate, and the composition of the waste feedstock must be carefully managed to ensure the desired output and prevent inefficient or hazardous operation.

Output Purification and Market Viability

The raw outputs—bio-oil, syngas, and bio-char—are not immediately ready for use. They often require costly purification and upgrading to meet market specifications, which can impact the overall economic viability of the operation.

Making the Right Choice for Your Goal

Pyrolysis is a powerful tool, but its application should be aligned with a clear strategic objective.

- If your primary focus is maximum volume reduction: Pyrolysis is highly effective, converting the bulk of solid waste into gas, liquid, and a smaller, stable solid residue.

- If your primary focus is resource recovery and revenue generation: Pyrolysis offers a clear pathway, but requires a thorough economic analysis of capital costs, operational energy needs, and the local market value for the refined end products.

- If your primary focus is creating a self-sustaining energy system: The ability to use syngas to power the process is a major advantage, but this requires careful engineering to balance energy production and consumption.

Ultimately, pyrolysis is a sophisticated engineering solution that treats waste not as an endpoint, but as a raw material for a new beginning.

Summary Table:

| Pyrolysis Output | Description | Potential Use |

|---|---|---|

| Bio-oil | Liquid fuel from decomposed waste | Industrial fuel, biofuels |

| Syngas | Combustible gas (H₂, CO) | Process heat, energy generation |

| Bio-char | Carbon-rich solid residue | Soil amendment, filtration media |

Ready to transform your waste management strategy with advanced pyrolysis solutions? KINTEK specializes in high-performance lab equipment and consumables for researching and optimizing pyrolysis processes. Whether you're developing new waste valorization techniques or scaling up your operations, our expertise can help you achieve precise temperature control, efficient resource recovery, and sustainable outcomes. Contact our experts today to discuss how we can support your laboratory and pilot-scale pyrolysis projects!

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Wall Mounted Water Distillation Unit

People Also Ask

- What is a rotary furnace used for? Achieve Unmatched Thermal Uniformity and Mixing

- What is refractory in rotary kiln? A Guide to Protecting Your Kiln and Maximizing Efficiency

- What are the process conditions during fast pyrolysis? Maximize Bio-Oil Yield with Precise Control

- What are the advantages of a continuous furnace? Achieve High-Volume, Consistent Thermal Processing

- What is safety in pyrolysis process? Managing Extreme Heat and Flammable Products

- What is the significance of calcination? A Guide to Purification and Metal Extraction

- How does pyrolysis work without oxygen? Transform Waste into Valuable Products

- What are the different types of calcination? Choosing the Right Method for Your Material