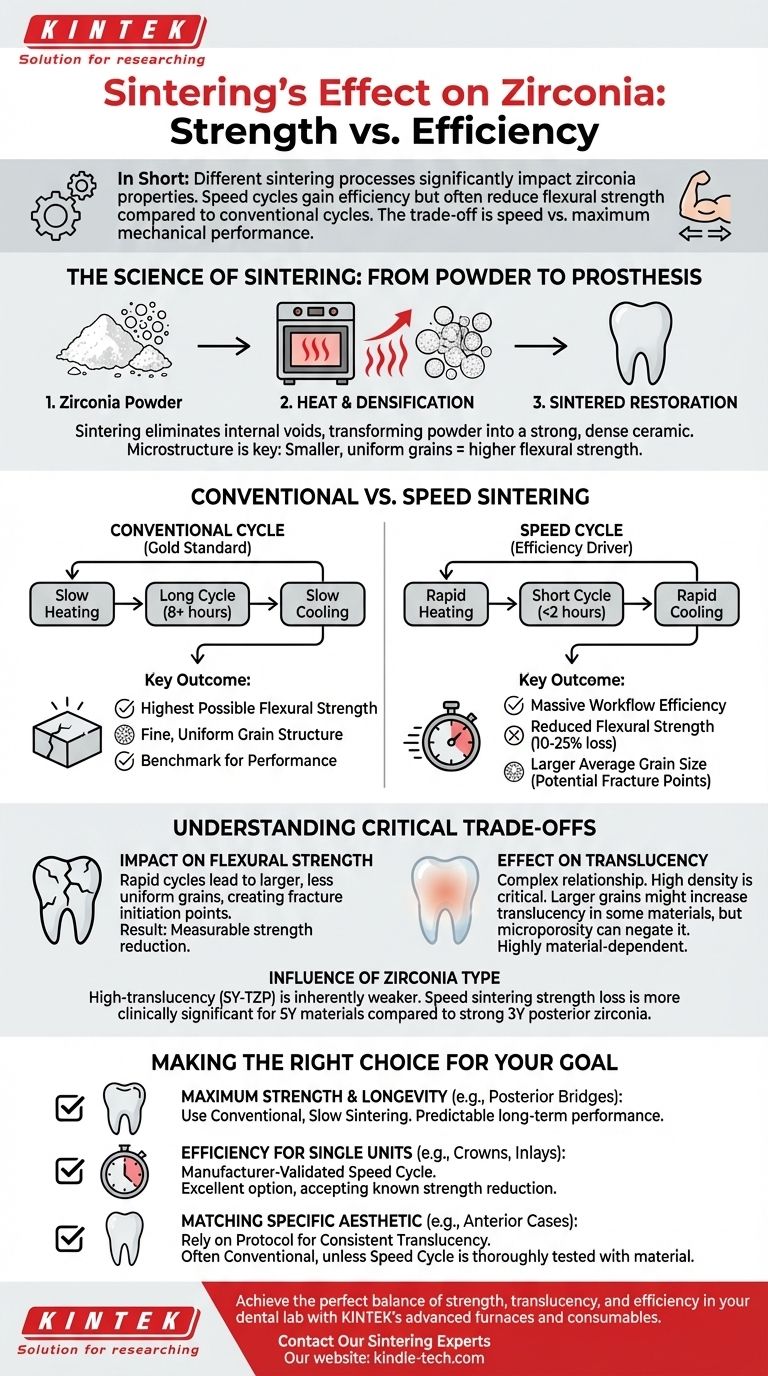

In short, different sintering processes significantly impact the final properties of translucent monolithic zirconia. While faster "speed" sintering cycles offer major efficiency gains, they often result in a measurable reduction in flexural strength compared to slower, conventional cycles. The effect on translucency is more complex and material-dependent, but the primary trade-off is one of speed versus maximum mechanical performance.

The choice between a conventional and a speed sintering cycle is not merely about saving time. It is a clinical and technical decision that directly alters the material's final microstructure, creating a critical balance between workflow efficiency, flexural strength, and aesthetics.

The Science of Sintering: From Powder to Prosthesis

The Goal of Sintering

Sintering is the critical step that transforms a chalk-like, porous zirconia block into a dense, strong ceramic restoration. The process uses heat to cause the individual zirconia particles to bond and compact together.

This densification process drastically reduces porosity. Eliminating these internal voids is what gives the final zirconia restoration its high flexural strength and structural integrity.

The Critical Role of Microstructure

The final properties of the sintered zirconia are determined by its internal microstructure, specifically the size and distribution of its crystalline grains.

In general, a microstructure with smaller, more uniform grains results in higher flexural strength. This is because it is more difficult for a crack to propagate through a dense network of small grains than it is to fracture across larger, irregular ones.

Conventional vs. Speed Sintering: A Direct Comparison

The Conventional Cycle: The Gold Standard

A conventional sintering cycle is a long, slow process, often taking 8 hours or more. It involves very gradual heating and cooling rates.

This deliberate pace allows for controlled, uniform grain growth, typically resulting in the fine-grained microstructure that yields the highest possible flexural strength for a given zirconia material. It is considered the benchmark for mechanical performance.

The Speed Cycle: The Efficiency Driver

Speed sintering cycles drastically shorten the process, often to under two hours. This is achieved through extremely rapid heating and cooling rates.

The obvious benefit is a massive improvement in workflow efficiency, enabling single-visit restorations and faster turnaround times for dental labs. This time savings, however, comes with important material science implications.

Understanding the Critical Trade-offs

The Impact on Flexural Strength

The rapid heating in a speed cycle can lead to less uniform grain growth, often resulting in larger average grain sizes. These larger grains can act as potential initiation points for fractures under stress.

Consequently, speed sintering almost always results in a reduction in flexural strength compared to the same material sintered conventionally. While modern materials are optimized to minimize this loss, a strength reduction of 10-25% is not uncommon, depending on the specific zirconia and furnace cycle used.

The Effect on Translucency

The relationship between sintering and translucency is complex. High density and low porosity are the biggest factors for good translucency, which both conventional and speed cycles aim to achieve.

However, grain size also plays a role. Some studies suggest that the larger grains produced by certain speed cycles can slightly increase translucency by reducing the number of grain boundaries that scatter light. This effect is not universal and can be negated if the cycle fails to eliminate all microporosity. The outcome is highly dependent on the specific material and furnace combination.

The Influence of Zirconia Type

The base material itself is a crucial variable. High-translucency zirconias (often called "anterior" or 5Y-TZP) are inherently weaker than high-strength zirconias (3Y-TZP).

A percentage-based strength reduction from speed sintering is therefore more clinically significant for an already weaker 5Y material. A strong 3Y posterior zirconia may still be more than strong enough for its purpose even after speed sintering, but the same cannot always be said for a 5Y material used in a high-stress situation.

Making the Right Choice for Your Goal

The decision of which cycle to use must be based on the clinical requirements of the specific case. There is no single "best" protocol; there is only the most appropriate protocol for the goal.

- If your primary focus is maximum strength and longevity (e.g., posterior long-span bridges): Use a conventional, slow sintering cycle to ensure the highest possible flexural strength and predictable long-term performance.

- If your primary focus is efficiency for single units (e.g., crowns, inlays): A manufacturer-validated speed sintering cycle is an excellent option, provided you accept the known reduction in peak strength.

- If your primary focus is matching a specific aesthetic (e.g., challenging anterior cases): Rely on the sintering protocol that gives you the most predictable and consistent translucency, which is often the conventional cycle unless you have thoroughly tested a speed cycle with your specific material.

By aligning your sintering protocol with the clinical demand, you move from simply following a program to strategically engineering the best possible outcome for each restoration.

Summary Table:

| Sintering Process | Cycle Time | Key Impact on Flexural Strength | Key Impact on Translucency | Best Use Case |

|---|---|---|---|---|

| Conventional | ~8+ hours | Highest strength (fine grain) | Consistent, predictable | Posterior long-span bridges, maximum longevity |

| Speed | <2 hours | Reduced strength (10-25% loss) | Material-dependent, variable | Single-unit crowns, inlays, efficiency-focused cases |

Achieve the perfect balance of strength, translucency, and efficiency in your dental lab. The right sintering protocol is critical for the clinical success of every zirconia restoration. At KINTEK, we specialize in providing advanced laboratory furnaces and consumables designed for precise, reliable sintering of all zirconia types. Our experts can help you select the ideal equipment to validate your sintering cycles and ensure consistent, high-quality results for every case. Contact us today to discuss your lab's specific needs and elevate your ceramic workflow.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the main disadvantage of dental ceramics? Balancing Aesthetics with Fracture Risk

- Are ceramic implants more expensive than titanium? Unpacking the Cost-Benefit Analysis

- What are dental furnaces used for? Essential for Crafting Durable & Aesthetic Dental Restorations

- How do you fix a broken ceramic tooth? Get Professional Repair & Restoration Solutions

- Which is cheaper porcelain or ceramic crown? A Practical Guide to Dental Crown Costs & Materials

- What are ceramics used for in dentistry? Achieve Natural-Looking, Durable Restorations

- What are the different types of temperature calibration systems used in porcelain furnaces? Ensure Precision for Every Ceramic Type

- How hot does a dental sintering furnace get? Unlock the Key to Perfect Restorations