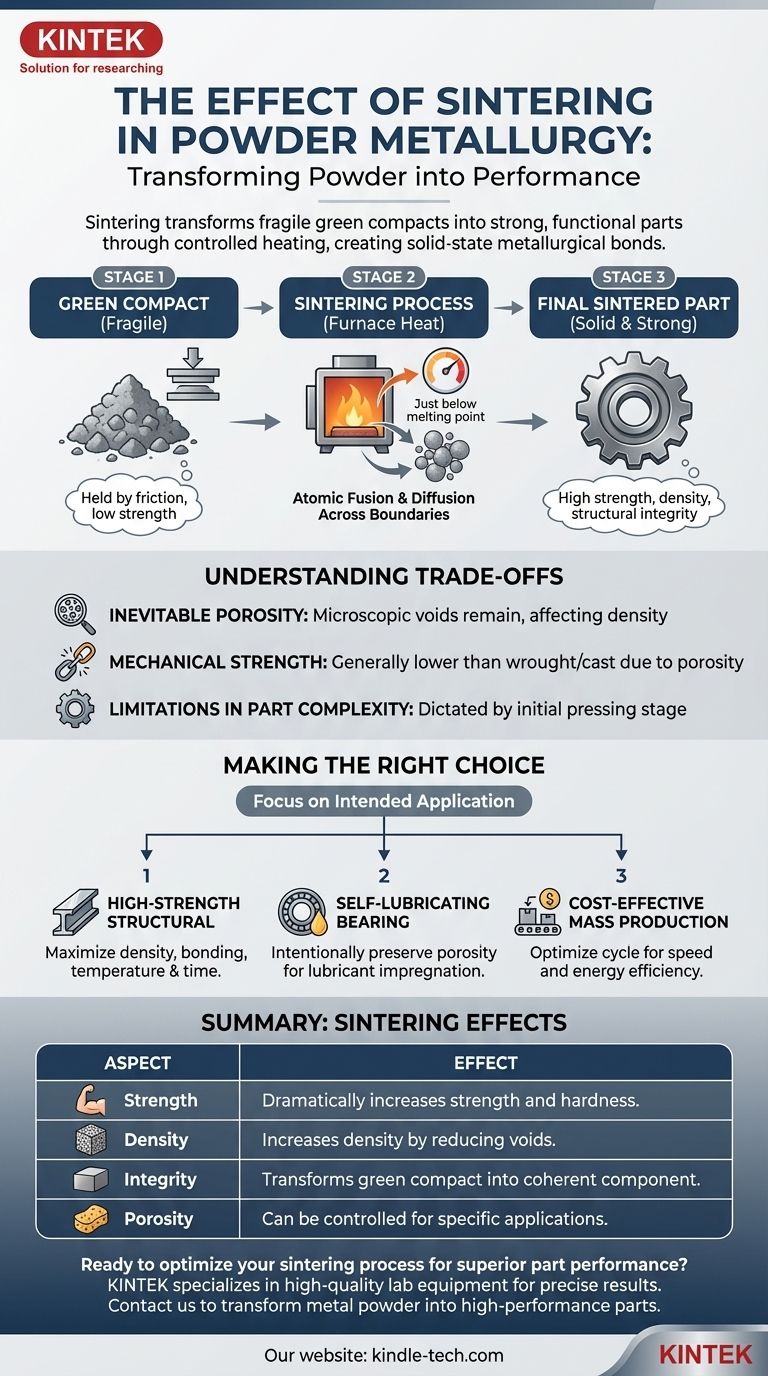

In powder metallurgy, the primary effect of sintering is to transform a fragile, compacted block of metal powder into a solid, coherent part with significant strength and integrity. This is achieved by heating the compacted material to a temperature just below its melting point, which causes the individual powder particles to fuse together into a solid-state bond.

Sintering is the critical step that converts a weakly-held shape of pressed powder into a functional engineering component. It's not about melting the material, but about using thermal energy to create powerful metallurgical bonds between particles, fundamentally changing the material's properties.

From Loose Powder to a Solid Part: The Role of Sintering

To understand the effect of sintering, we must first look at the state of the material before this process begins. The initial part is merely powder that has been mechanically pressed into a shape.

The "Green" Compact State

Before sintering, the component is known as a "green" compact. This part has the desired shape but possesses very little mechanical strength. It is brittle and can be easily broken, as the metal particles are only held together by friction and the cold welds formed during compaction.

The Mechanism of Atomic Fusion

Sintering applies controlled heat in a furnace, raising the temperature to just below the material's melting point. This thermal energy allows atoms to diffuse across the boundaries of adjacent powder particles. This process fuses the particles together at their points of contact, much like ice cubes left in a glass of water will slowly fuse into a single mass.

Imparting Mechanical Properties

This atomic-level fusion is what creates a strong, continuous metallic structure. The direct effect is a dramatic increase in the part's strength, hardness, and overall structural integrity. Without sintering, a powder metallurgy part would remain a fragile green compact, unsuitable for any practical application.

Achieving Final Density and Shape

As the particles bond, the voids or pores between them shrink, which increases the density of the component. This process ensures the part achieves its required final physical properties and dimensional accuracy, making it ready for its end-use.

Understanding the Trade-offs

While essential, the sintering process and the powder metallurgy method as a whole involve inherent compromises that must be considered.

The Inevitability of Porosity

A key characteristic of most sintered parts is the presence of some level of porosity. It is very difficult and often not cost-effective to achieve 100% density. These microscopic voids remain from the spaces between the original powder particles.

Impact on Mechanical Strength

Because of this residual porosity, a sintered component is often less strong than a part made from solid wrought metal or through casting. The pores can act as stress concentration points, which can slightly reduce the part's overall tensile strength and ductility.

Limitations in Part Complexity

The limitations of the initial powder pressing stage can dictate the complexity of the final part. While sintering solidifies the component, it cannot add complex features that weren't present in the green compact.

Making the Right Choice for Your Goal

The specific parameters of the sintering process are adjusted based on the intended application of the final component.

- If your primary focus is a high-strength structural part: You will aim to maximize density and bonding by optimizing temperature and time to achieve the highest possible mechanical properties.

- If your primary focus is a self-lubricating bearing: You will intentionally preserve a certain level of porosity, which can then be impregnated with a lubricant.

- If your primary focus is cost-effective mass production: You will optimize the sintering cycle for speed and energy efficiency while ensuring the part meets its minimum performance specifications.

Ultimately, mastering the sintering process is about precisely controlling heat to transform simple metal powder into a component with purpose-built properties.

Summary Table:

| Aspect | Effect of Sintering |

|---|---|

| Mechanical Strength | Dramatically increases strength and hardness by creating solid-state bonds between particles. |

| Density | Increases part density by reducing voids and pores between particles. |

| Structural Integrity | Transforms a fragile 'green' compact into a solid, coherent engineering component. |

| Porosity | Can be controlled; some porosity may be retained for specific applications like self-lubricating bearings. |

Ready to optimize your sintering process for superior part performance?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your powder metallurgy needs. Whether you're developing high-strength structural components or cost-effective mass-produced parts, our expertise and reliable solutions ensure you achieve precise temperature control and consistent results.

Contact us today to discuss how we can support your laboratory's sintering applications and help you transform metal powder into high-performance parts.

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics

- What is the primary function of a vacuum hot pressing sintering furnace? Expert Guide for Ti-22Al-25Nb Fabrication

- What critical processing conditions does a vacuum hot pressing sintering furnace provide for high-density VC/Cu?