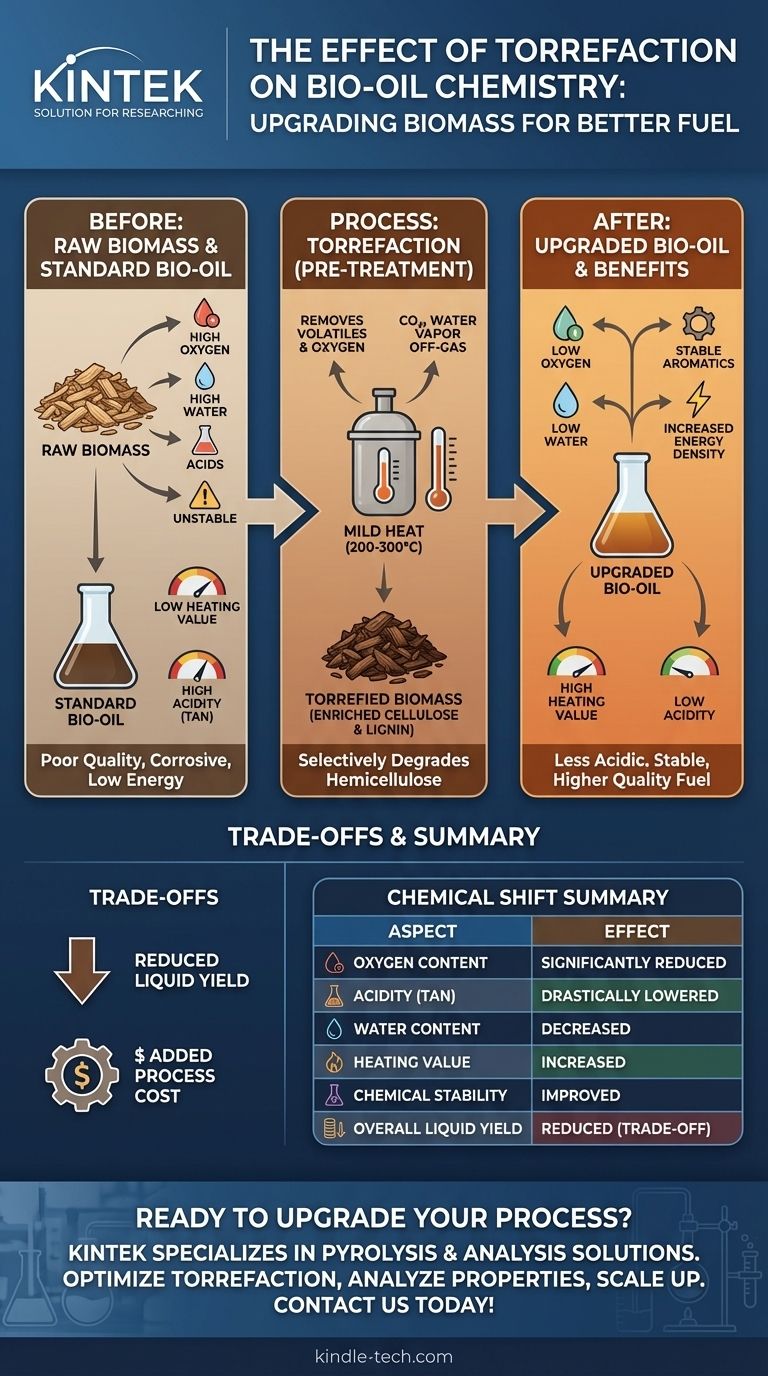

Torrefaction fundamentally alters the chemistry of fast pyrolysis bio-oil by reducing its oxygen content and increasing the concentration of stable, energy-dense compounds. This pre-treatment step roasts the initial biomass in an inert environment, breaking down its most reactive and oxygen-rich components before they enter the pyrolysis reactor. As a result, the final bio-oil produced is less acidic, contains less water, and has a higher heating value, directly addressing the core quality issues that limit its use as a fuel.

The central challenge with standard bio-oil is its poor quality, driven by high acidity and low energy density. Torrefaction is a strategic pre-treatment that upgrades the biomass itself, leading to the direct production of a higher-quality, more stable bio-oil that more closely resembles conventional fuel oil.

Why Bio-Oil Quality is a Problem

To understand the impact of torrefaction, we must first recognize the inherent chemical limitations of bio-oil produced from raw biomass. These issues stem directly from the chemical composition of the plant matter itself.

High Oxygen and Water Content

Raw biomass contains a significant amount of oxygen locked in its molecular structure. During fast pyrolysis, this oxygen is carried over into the bio-oil, primarily in the form of water, acids, aldehydes, and ketones. This high oxygen content is the main reason for bio-oil's low heating value, which is often half that of petroleum fuels.

Inherent Acidity and Corrosiveness

The breakdown of hemicellulose, a primary component of biomass, yields large quantities of carboxylic acids, particularly acetic and formic acid. These acids make the bio-oil highly corrosive to standard steel pipes and engines, requiring expensive, specialized materials for handling and storage.

Chemical Instability

Bio-oil is a complex mixture containing highly reactive compounds like aldehydes and ketones. Over time, these molecules react with each other, forming larger polymers. This aging process increases the bio-oil's viscosity, making it difficult to pump and use.

How Torrefaction Upgrades the Feedstock

Torrefaction is a mild thermal treatment (200-300°C) that fundamentally changes the biomass before it undergoes pyrolysis. This is the key to improving the final product.

Selectively Degrading Hemicellulose

Hemicellulose is the least stable polymer in biomass and the main source of acids and water in the resulting bio-oil. Torrefaction selectively targets and breaks down this component, driving off its volatile and oxygen-rich elements as gases (like CO2) and water vapor.

Concentrating Lignin and Cellulose

By removing the most reactive parts of the hemicellulose, the remaining solid biomass becomes enriched in cellulose and lignin. These components are more energy-dense and tend to produce more valuable aromatic and phenolic compounds during pyrolysis, rather than corrosive acids.

The Resulting Chemical Shift in the Bio-Oil

When this torrefied, upgraded biomass is fed into a pyrolysis reactor, the chemical profile of the resulting bio-oil is dramatically improved.

Drastically Reduced Acidity

Because the hemicellulose precursors were already removed, the formation of acetic and formic acid during pyrolysis is significantly suppressed. This directly lowers the bio-oil's Total Acid Number (TAN), making it far less corrosive.

Lower Water Content

The torrefaction process removes both free water from the biomass and the oxygen-containing functional groups that would have formed water during pyrolysis. A lower water content in the final bio-oil directly translates to a higher energy density.

Increased Aromatic Compounds

The pyrolysis of a lignin-rich feedstock yields a higher proportion of stable phenolic and aromatic compounds. These molecules are not only more stable over time but also contribute significantly to the bio-oil's heating value. This improves the overall stability and quality of the liquid fuel.

Understanding the Trade-offs

While torrefaction offers significant chemical benefits, it is not without its challenges. An objective assessment requires acknowledging the drawbacks.

Reduced Overall Liquid Yield

The primary trade-off is a decrease in the total volume of bio-oil produced per ton of raw biomass. The torrefaction step drives off volatile matter that would have otherwise become part of the liquid product. You get a higher-quality oil, but you may get less of it.

Added Process Complexity and Cost

Integrating a torrefaction unit adds significant capital and operational expense to a biorefinery. The economic viability depends on whether the increased value and marketability of the upgraded bio-oil can offset these additional costs.

Net Energy Balance

The torrefaction process itself requires a significant energy input to heat the biomass. While the combustible gases produced during torrefaction can be used to offset some of this energy demand, the overall energy balance of the integrated process must be carefully analyzed.

Making the Right Choice for Your Goal

The decision to use torrefaction depends entirely on the desired characteristics of the final product.

- If your primary focus is maximizing liquid fuel volume: Torrefaction may be counterproductive, as it is known to decrease the total bio-oil yield per ton of initial raw biomass.

- If your primary focus is producing a high-quality, stable drop-in fuel: Torrefaction is a highly effective pre-treatment for reducing acidity, lowering water content, and increasing the energy density of the final bio-oil.

- If your primary focus is economic viability: You must conduct a thorough techno-economic analysis comparing the added cost of the torrefaction unit against the increased market value of the upgraded, less corrosive bio-oil.

Ultimately, torrefaction is a strategic lever for trading bio-oil quantity for a significant and necessary improvement in its quality.

Summary Table:

| Aspect | Effect of Torrefaction |

|---|---|

| Oxygen Content | Significantly Reduced |

| Acidity (TAN) | Drastically Lowered |

| Water Content | Decreased |

| Heating Value | Increased |

| Chemical Stability | Improved |

| Overall Liquid Yield | Reduced (Trade-off) |

Ready to upgrade your biomass conversion process and produce a higher-value bio-oil?

At KINTEK, we specialize in advanced laboratory equipment for pyrolysis and biomass analysis. Our solutions help researchers and engineers optimize pre-treatment processes like torrefaction to achieve the specific fuel quality and stability goals outlined in this article.

Let us help you:

- Test and optimize torrefaction parameters for your specific biomass feedstock.

- Analyze the chemical properties of your upgraded bio-oil with precision.

- Scale your process from the lab to pilot and production with reliable equipment.

Contact us today to discuss how our expertise in lab equipment and consumables can advance your bio-fuel research and development. Get in touch with our experts now!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- How does a rotary extractor work? Master Continuous High-Volume Solid Processing

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the drying zone in a rotary kiln? Boost Efficiency with Modern Drying Solutions

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment