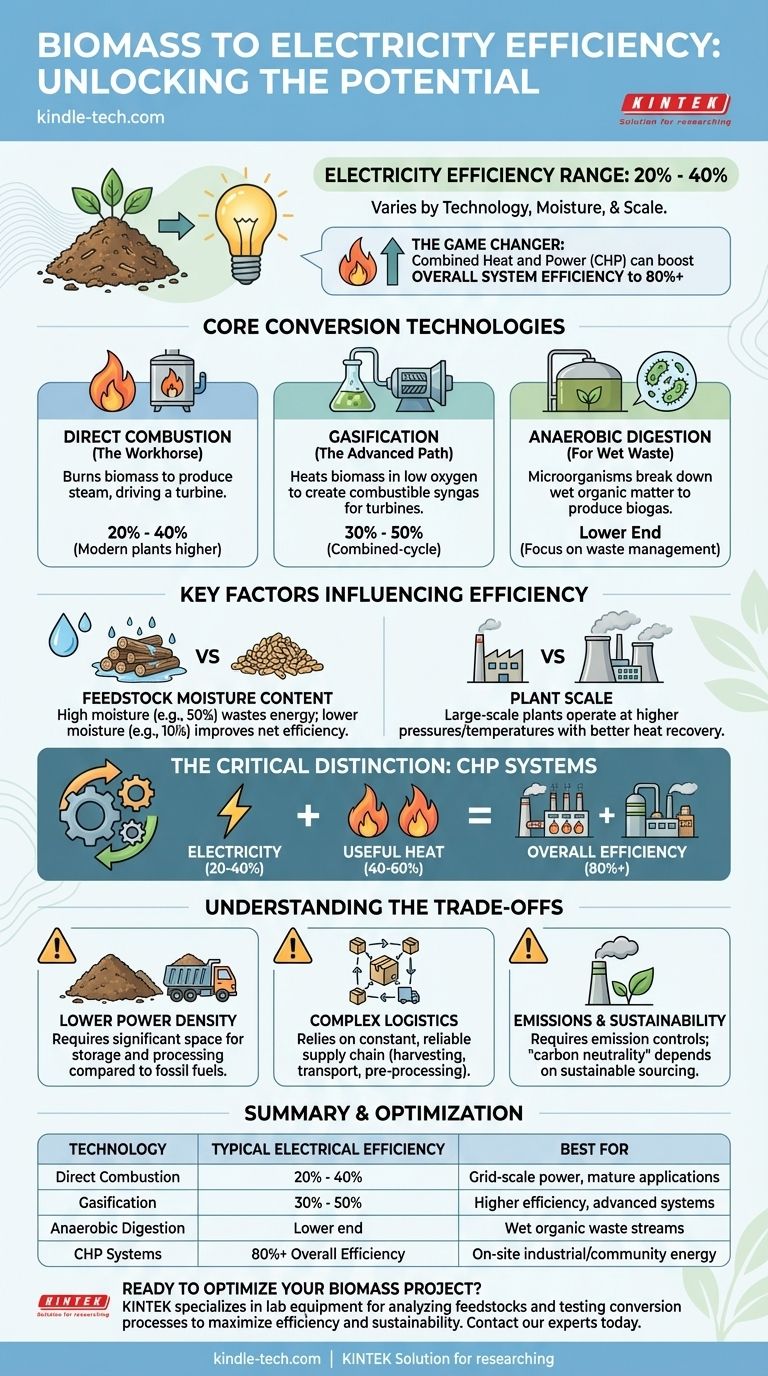

To be clear, the efficiency of converting solid biomass into electricity typically ranges from 20% to 40%. This wide variation is not arbitrary; it is dictated primarily by the specific conversion technology used, the moisture content of the biomass feedstock, and the scale of the power plant.

The central challenge with biomass is that while its electrical efficiency seems modest, this single metric overlooks its unique value. The true potential of biomass is often unlocked in Combined Heat and Power (CHP) systems, where "waste" heat is captured, pushing total system efficiencies above 80%.

The Core Conversion Technologies

To understand the efficiency range, you must first understand the primary methods used to generate power from biomass. Each operates on different principles and offers a distinct efficiency profile.

Direct Combustion (The Workhorse)

This is the most common and mature technology. Biomass, such as wood chips or agricultural residue, is burned in a boiler to produce high-pressure steam.

This steam then drives a turbine connected to a generator, similar to a conventional coal-fired power plant.

For most plants, especially older or smaller ones, the efficiency of this process hovers between 20% and 30%. Modern, large-scale facilities can push towards 40%.

Gasification (The Advanced Path)

Gasification does not burn the biomass directly. Instead, it heats it in a low-oxygen environment to produce a combustible gas known as syngas.

This syngas is then cleaned and can be burned much more efficiently in a gas turbine or a high-efficiency engine.

This multi-step process allows for higher electrical efficiencies, typically in the 30% to 50% range, especially when implemented in a combined-cycle configuration.

Anaerobic Digestion (For Wet Waste)

This is a biological process, not a thermal one. It uses microorganisms to break down wet organic materials (like manure, sewage sludge, or food waste) in an oxygen-free environment.

The process produces biogas, which is primarily methane. This biogas is then used to fuel an engine-generator set.

While essential for waste management, the electrical efficiency is often on the lower end, but it solves a critical waste disposal problem simultaneously.

Key Factors That Dictate Efficiency

Beyond the choice of technology, several physical and operational factors have a significant impact on the final net efficiency of a biomass plant.

Feedstock Moisture Content

A substantial amount of energy can be wasted just to boil off the water present in the biomass before useful energy can be released.

A feedstock with 50% moisture content (like green wood chips) will lead to a much lower net plant efficiency than one with 10% moisture content (like dried wood pellets).

Plant Scale

Large-scale power plants are inherently more efficient than smaller ones.

They can operate at higher steam pressures and temperatures and incorporate more complex heat recovery systems, minimizing energy loss and maximizing output per unit of fuel.

The Critical Distinction: Electrical vs. Overall Efficiency

Focusing solely on the electricity generated can be misleading. The most effective biomass applications often capture and use the enormous amount of heat produced during the process.

This is the principle of Combined Heat and Power (CHP), also known as cogeneration.

By using the "waste" heat for industrial processes, district heating, or drying applications, the overall system efficiency can exceed 80% or even 90%. This dramatically changes the economic and environmental calculus.

Understanding the Trade-offs

While a valuable renewable resource, biomass energy is not without its challenges and limitations. An objective assessment requires acknowledging these trade-offs.

Lower Power Density

Biomass is bulky and has a lower energy content by volume and weight compared to fossil fuels.

This means significant physical space is required for fuel storage, handling, and processing, which impacts the plant's footprint and logistics.

Complex Feedstock Logistics

Unlike a gas pipeline, biomass requires a constant and reliable supply chain of physical material.

This involves harvesting, collection, transportation, and pre-processing, which adds operational complexity, cost, and can have its own carbon footprint.

Emissions and Sustainability

While often considered carbon-neutral, combustion still produces local air pollutants like nitrogen oxides (NOx) and particulate matter that require control technologies.

Furthermore, the "carbon neutrality" of biomass is critically dependent on the sustainable sourcing of the feedstock, ensuring that the carbon released is recaptured by new growth.

Making the Right Choice for Your Goal

The optimal approach to biomass energy depends entirely on your primary objective.

- If your primary focus is maximizing grid-scale electricity: Invest in large, modern plants using dry feedstocks with advanced direct combustion or gasification combined-cycle technology.

- If your primary focus is on-site industrial or community energy: Prioritize a Combined Heat and Power (CHP) system to achieve the highest overall efficiency and economic return by using both electricity and heat.

- If your primary focus is managing organic waste streams: Anaerobic digestion is the purpose-built solution, turning a liability into a valuable energy resource.

Ultimately, viewing biomass not as a universal replacement but as a strategic tool for specific applications is the key to leveraging its true potential.

Summary Table:

| Technology | Typical Electrical Efficiency | Best For |

|---|---|---|

| Direct Combustion | 20% - 40% | Grid-scale power, mature applications |

| Gasification | 30% - 50% | Higher efficiency, advanced systems |

| Anaerobic Digestion | Lower end (waste management focus) | Wet organic waste streams |

| CHP Systems | 80%+ Overall Efficiency | On-site industrial/community energy |

Ready to optimize your biomass energy project? KINTEK specializes in lab equipment and consumables for analyzing biomass feedstocks, testing conversion processes, and ensuring the quality of your biofuels. Whether you're developing a new gasification system or optimizing a CHP plant, our analytical tools help you achieve maximum efficiency and sustainability. Contact our experts today to discuss how we can support your laboratory's critical role in the future of biomass energy.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Gold Disc Electrode

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is the RRDE in electrochemistry? Unlock Detailed Reaction Pathways with Dual-Electrode Analysis

- What is the application of RRDE? Unlock Quantitative Catalyst and Reaction Insights

- What are the performance characteristics of platinum wire/rod electrodes? Unmatched Stability for Your Lab

- What is a common application for the platinum wire/rod electrode? The Essential Guide to Counter Electrodes

- What is the rotating ring disk electrode method? Unlock Real-Time Reaction Analysis