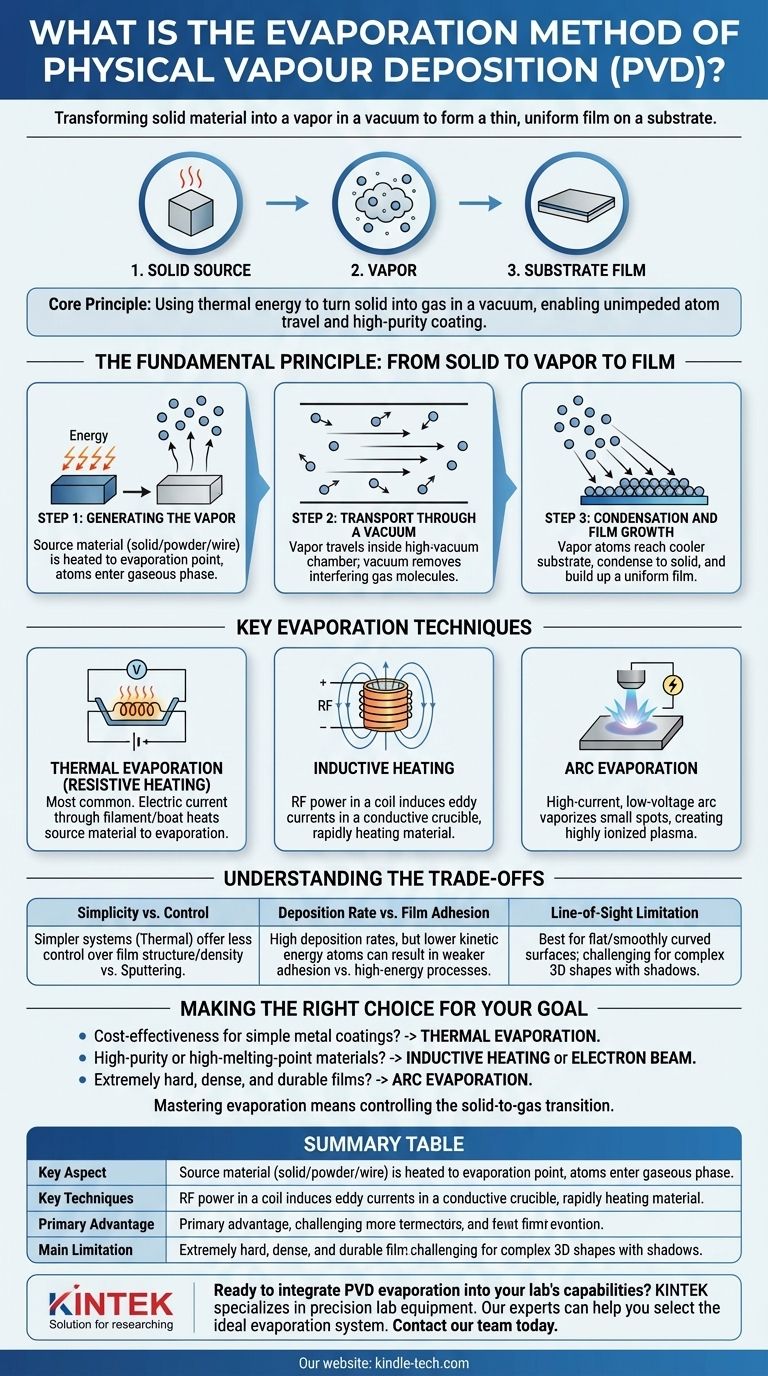

In physical vapor deposition (PVD), the evaporation method is a family of processes where a source material is heated in a vacuum chamber until it transforms into a vapor. This vapor then travels through the vacuum and condenses onto a cooler surface, known as the substrate, forming a thin, uniform film.

The core principle is simple: use thermal energy to turn a solid material into a gas within a vacuum. This allows its atoms to travel unimpeded and deposit onto a target surface, creating a high-purity coating.

The Fundamental Principle: From Solid to Vapor to Film

The entire process is governed by a straightforward, three-step sequence that takes place under controlled vacuum conditions.

Step 1: Generating the Vapor

The process begins by supplying energy to a source material, often in the form of a solid block, powder, or wire. This energy heats the material to its evaporation point, causing its atoms to break free from the surface and enter a gaseous phase.

Step 2: Transport Through a Vacuum

This vapor phase occurs inside a high-vacuum chamber. The vacuum is critical because it removes air and other gas molecules that would otherwise collide with the vapor atoms, scattering them and introducing impurities. In a vacuum, the vapor atoms travel in a straight, line-of-sight path from the source to the substrate.

Step 3: Condensation and Film Growth

When the vapor atoms reach the cooler substrate, they lose energy and condense back into a solid state. They adhere to the surface and gradually build up, atom by atom, to form a thin, solid film with the same chemical composition as the source material.

Key Evaporation Techniques

While the principle remains the same, different methods are used to supply the energy required for evaporation. The choice of technique depends on the material being deposited and the desired film properties.

Thermal Evaporation (Resistive Heating)

This is the most common and direct method. An electric current is passed through a high-resistance filament or "boat" (often made of tungsten or molybdenum) that holds the source material. The boat heats up, transferring thermal energy to the material and causing it to evaporate.

Inductive Heating

In this technique, a crucible containing the source material is placed inside a coil. A high-frequency alternating current (RF power) is run through the coil, which generates a changing magnetic field. This field induces eddy currents within the conductive crucible, causing it to heat up rapidly and evaporate the material inside.

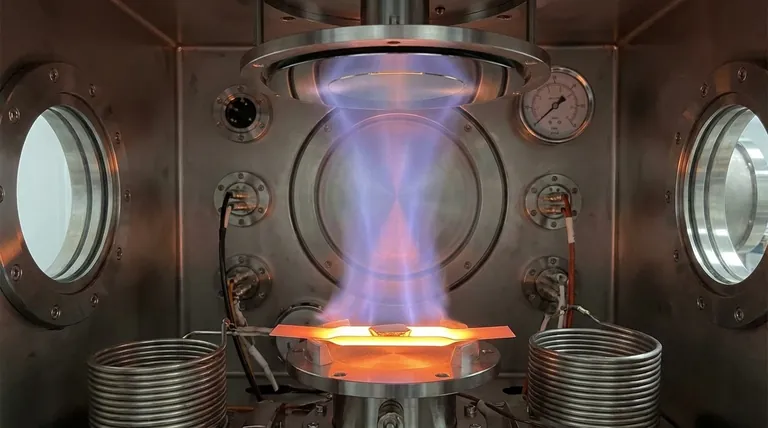

Arc Evaporation

This is a higher-energy process used for creating very hard and dense films. A high-current, low-voltage electric arc is ignited on the surface of the solid source target. The intense energy of the arc vaporizes small spots of the material, creating a highly ionized vapor, or plasma, which is then directed toward the substrate.

Understanding the Trade-offs

Evaporation is a powerful PVD method, but it's important to understand its characteristics compared to other techniques like sputtering.

Simplicity vs. Control

Evaporation systems, particularly thermal evaporation, are often simpler and less expensive to operate. However, they can offer less control over the film's structure and density compared to sputtering.

Deposition Rate vs. Film Adhesion

Evaporation can achieve very high deposition rates, making it efficient for some applications. However, because the vapor atoms arrive with relatively low kinetic energy, the adhesion of the film to the substrate can sometimes be weaker than films produced by higher-energy processes like arc evaporation or sputtering.

Line-of-Sight Limitation

Because the vapor travels in a straight line, evaporation is best suited for coating flat or smoothly curved surfaces. It can be challenging to achieve a uniform coating on complex, three-dimensional shapes with shadowed areas.

Making the Right Choice for Your Goal

Selecting the appropriate evaporation technique is a matter of matching the process capabilities to your specific requirements for the material and the final film.

- If your primary focus is cost-effectiveness for simple metal coatings: Thermal (resistive) evaporation is often the ideal choice due to its simplicity and high deposition rates.

- If your primary focus is depositing high-purity or high-melting-point materials: Inductive heating or electron beam evaporation (a related technique) provides the necessary energy without direct contact from a heating element.

- If your primary focus is creating extremely hard, dense, and durable films: Arc evaporation is superior, as the plasma it generates results in a more robust and adherent coating.

Ultimately, mastering the evaporation method means understanding that you are simply controlling the transition of matter from a solid to a gas and back again.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Heating a solid source material in a vacuum until it vaporizes and condenses on a substrate. |

| Key Techniques | Thermal (Resistive), Inductive (RF), Arc Evaporation. |

| Primary Advantage | High deposition rates and high-purity films. |

| Main Limitation | Line-of-sight deposition, less suitable for complex 3D shapes. |

Ready to integrate PVD evaporation into your lab's capabilities? KINTEK specializes in precision lab equipment and consumables. Our experts can help you select the ideal evaporation system—whether it's cost-effective thermal evaporation for simple coatings or advanced arc evaporation for durable films—to meet your specific research and production goals. Contact our team today to discuss your project and discover the KINTEK difference in laboratory performance.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the uses of thermal evaporation? Essential for Electronics, Optics & Decorative Finishes

- What are the applications of electron beams? From Nanoscale Imaging to Industrial Manufacturing

- What is the difference between thermal evaporation and e beam evaporation? Choose the Right Method for Your Thin Film

- What is the pressure for electron beam evaporation? Master the Key to High-Purity Thin Films

- How does a molybdenum evaporation source function in H2S for MoS2 synthesis? Master Reactive Film Deposition

- What are the applications of thin film in electronics? Building the Foundation of Modern Devices

- What are the advantages and disadvantages of e-beam evaporation? High Purity Films for Demanding Applications

- What is electron beam assisted evaporation used for? Achieve Superior Thin Film Coatings